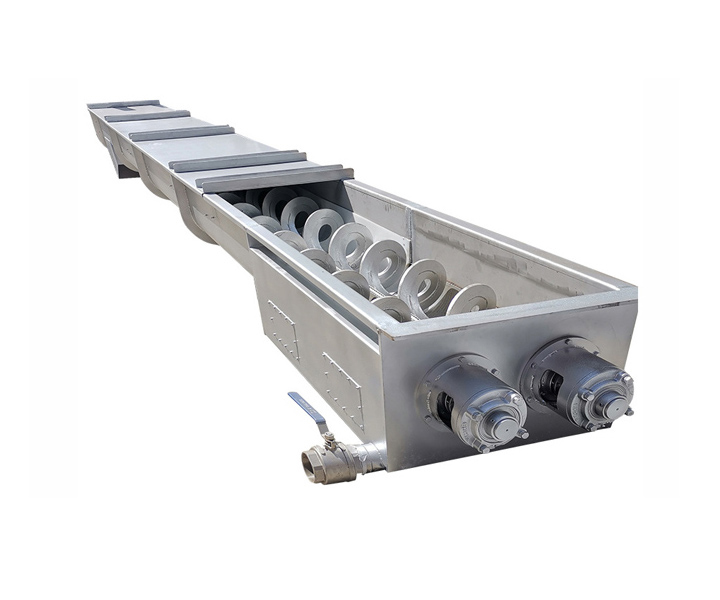

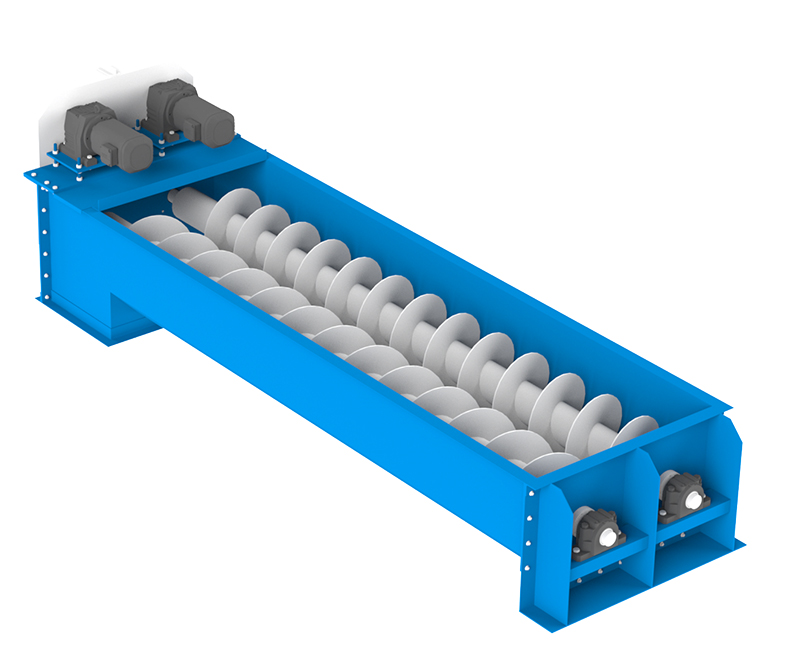

With the functions of mixing, stirring, cooling, etc., the two screw shafts rotate in opposite directions, and it is not easy to block the material. The conveying capacity is 1.5-2 times that of a single shaft.

![]()

![]()

![]()

Price:$500.00-$5,500.00/Set

Consult now and enjoy a 10% discount

Width or Diameter: 200mm-600mm

Type: Double shaft or double shaftless

Delivery capacity: 458 cubic meters per hour

Conveying length: 2-70 meters

Tilt angle: 0-15° Frame Material: SUS304/Carbon Steel

Applicable materials: cement, sludge, slag, household garbage, chemical raw materials, waste paper pulp, coal powder, etc.

Application fields: building materials, metallurgy, chemical industry, mining, coal, tobacco, food, medicine and other industries

Twin screw conveyor is a material handling device used to move bulk materials horizontally or inclined. It consists of two parallel screws rotating in opposite directions, creating a fluidization effect that allows the material to move smoothly along the conveyor. The twin screw conveyor is designed with a groove or housing that contains the helix. Screws are usually made of metal and powered by an electric motor. As they rotate, the screws move material along the length of the conveyor. Ideal for handling sticky, viscous or materials that are difficult to move with other types of conveyors. The fluidization effect created by the twin screws helps break up clumps and makes it easier for the material to move along the length of the conveyor.

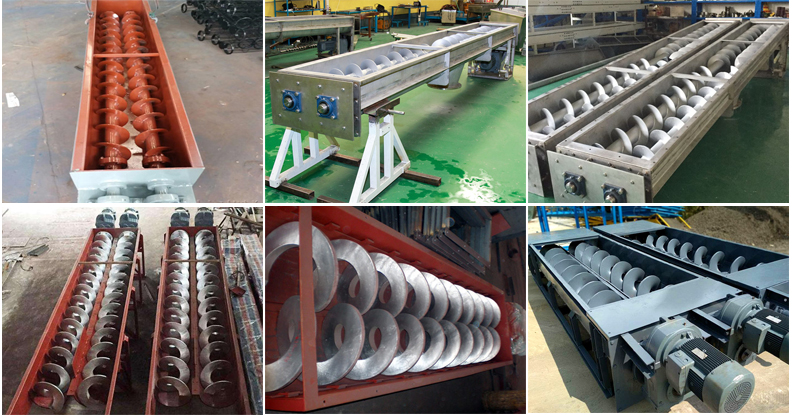

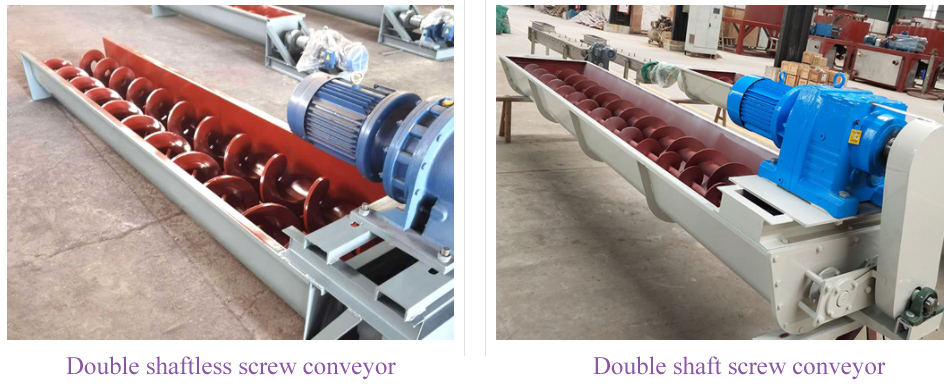

1. Different structures

Twin-shaft screw conveyor: It can transport materials that are not easy to stick and have a certain friction force, which has certain requirements for the wear resistance of the screw conveyor.

Twin- shaftless screw conveyor: it can transport granular/powder/wet/paste, semi-fluid/viscous materials, such as sludge, domestic garbage, etc., and is also suitable for materials with special hygienic requirements.

2. Different materials

Stainless steel material: This material has anti-oxidation, anti-corrosion effects and is easy to clean, so it is more popular in food, chemical, pharmaceutical and other industries.

Carbon steel material: The equipment material is a low-cost material, and the price is convenient, which has certain advantages and is suitable for a wide range of materials.

Manganese steel material: Manganese steel is a common material for mining, with strong wear resistance and toughness, so it has great advantages for mines and some relatively rough material transportation.

The purpose of a twin screw conveyor is to move bulk material horizontally or inclined in a controlled and efficient manner. Twin screw conveyors are used for material handling in a variety of industries including food processing, pharmaceuticals, chemical manufacturing, construction and mining.

Some specific uses for twin screw conveyors include:

1. Mixing and mixing: It can be used to mix and mix different materials to ensure that the materials are fully mixed before further processing or packaging.

2. Metering: It can be used to accurately meter a specific quantity of material, ensuring that the correct amount of material is delivered to the next stage of the production process.

3. Cooling or heating: the shell with jacket can be designed, which can be heated or cooled to maintain the temperature of the conveyed material.

4. Conveying: It can be used to convey bulk materials from one location to another, with the ability to move materials horizontally, inclined or vertically.

twin screw conveyor for concrete

twin screw conveyor for sawdust

The working principle of a twin screw conveyor involves the use of two parallel screws that rotate in opposite directions to move bulk materials horizontally or at an incline. Here is a step-by-step explanation of how a twin screw conveyor works:

1. Material Loading: The bulk material is loaded onto the inlet of the conveyor.

2. Screw Rotation: The twin screws, which are powered by a motor, begin to rotate in opposite directions.

3. Material Transport: As the screws rotate, they move the material along the length of the conveyor, with the screw flights acting as a screw pump and pushing the material forward.

4. Mixing and Fluidizing: The screws also create a fluidizing effect that helps to break up clumps and mix the material, ensuring that it moves smoothly along the conveyor.

5. Discharge: The material is discharged from the outlet of the conveyor, where it can be collected or further processed.

The speed and direction of the screws can be adjusted to control the rate of material flow and ensure that the material is handled gently and with minimal degradation. The twin screw conveyor can also be customized with different screw geometries, outlet configurations, and materials of construction to meet specific material handling requirements.

Efficient material handling

For efficient movement of bulk materials, reducing the time and energy required for material handling.

Has many uses

A wide range of materials can be handled including powders, granules and sticky or sticky materials.

Gentle material handling

The fluidization effect created by the twin screws helps prevent damage or breakage of the material being transported, ensuring gentle material handling and minimal degradation.

Customizable design

Twin screw conveyors can be customized to meet specific material handling requirements, with different screw geometries, outlet configurations and materials of construction.

Low maintenance

Requiring minimal maintenance, no lubrication or frequent adjustments, low operating costs and long service life.

Health

Can be designed with food-grade materials for easy cleaning and sanitization, making them ideal for food processing and other hygienic applications.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.