bucket elevator

bucket elevator continuous bucket elevator

continuous bucket elevator chain bucket elevator

chain bucket elevator plate chain bucket elevator

plate chain bucket elevator z type bucket elevator

z type bucket elevator

For vertical conveying of large volumes of material, from heavy iron ore pellets to sand, fly ash and other pulverized, pulverized, dry materials.

![]()

![]()

![]()

Price:$500.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Type: Belt/Chain

Material particle size: 25-70mm

Lifting capacity: 5.4-142 tons/hour

Lifting height: ≤40 meters

Lifting speed: 1.4-2 m/s

Material: carbon steel, stainless steel

Application: Continuous vertical lifting of powdery, granular and small materials. It can be widely used in feed mills, flour mills, rice mills and oil plants of various sizes.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

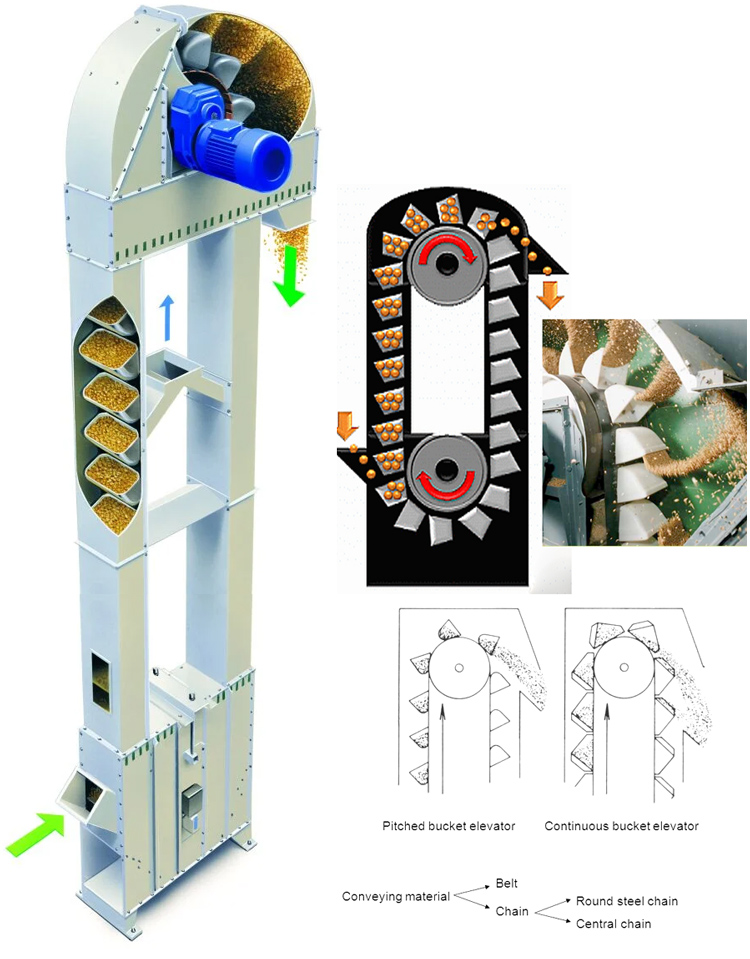

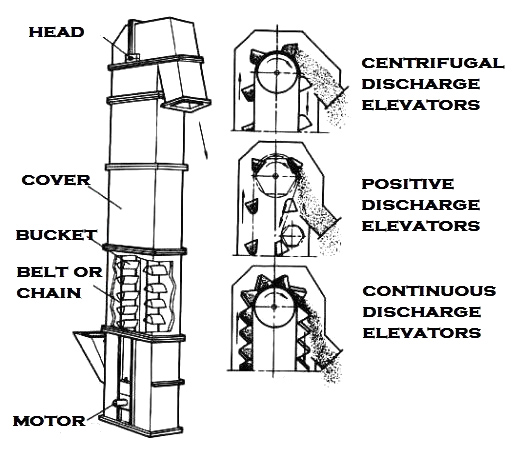

Bucket elevator is a conveyor system consisting of a series of buckets attached to chains or belts that move the buckets vertically between the different levels of the production line, used to vertically transport bulk materials such as grain, fertilizer, or sand.

The buckets on a bucket elevator are usually made of durable materials such as steel or plastic and are designed to scoop up material as the elevator moves up. Then, the bucket unloads the materials on the top of the elevator, where they can be directed to storage bins or other processing equipment, which can be widely used in feed mills, flour mills, rice mills, oil plants of all sizes, starch plants, Vertical transportation of bulk materials in grain warehouses, ports and other occasions.

According to the characteristics and process requirements of bulk materials, Dahan Machinery has designed and manufactured a wide variety of bucket elevators to meet the needs of many industries.

Belt Type Bucket Elevator

The use of belt + hopper to lift and transport materials has been involved in grain, coal, fly ash, cement, crushed ore, quartz sand, carbon and other industries, and has been well applied.

Delivery capacity: 400 cubic / hour

Lifting height: 40 meters

Chain Bucket Elevator

The circular chain or leaf chain is used as the traction component, which has good wear resistance and reliability, and is suitable for vertical lifting of powdery, granular, and small pieces of low-abrasive materials, such as: coal, cement, gravel, sand, Fertilizer, etc.

Delivery capacity: 5.4-365 cubic/hour

Lifting height: 40 meters

Z Type Bucket Elevator

Horizontal-vertical-horizontal combined conveying, suitable for packaging and conveying into warehouses of bulk products, such as feed, plastic granules, potato chips, low material damage rate, single-point or multi-point feeding.

Discharge height: 1.5-12m

Feeding length: ≤1.3m

The working principle of a bucket elevator is relatively straightforward. The elevator consists of a series of buckets that are attached to a chain or belt, which moves the buckets vertically between different levels of a production line.

Here is a step-by-step breakdown of how a bucket elevator works:

1. Loading: The bulk material is loaded into the buckets at the bottom of the elevator, either manually or through an automated feeding mechanism.

2. Upward Movement: As the elevator chain or belt moves upward, the buckets are lifted and transported vertically to the top of the elevator.

3. Discharge: At the top of the elevator, the buckets are tipped over, allowing the material to fall into a storage bin or other processing equipment.

4. Return: After the buckets are emptied, they continue their downward movement and return to the bottom of the elevator to be loaded again.

The movement of the bucket elevator is driven by a motor, which powers the chain or belt that moves the buckets. The speed of the elevator can be adjusted to control the rate of material transport.

Vertical transport

Designed for vertical transport of bulk materials, it is ideal for applications where materials need to be moved between different levels of the production line.

High capacity

Large quantities of material can be handled over long distances, making it an efficient way to move bulk materials. The lifting volume can reach 830 cubic meters per hour, and can be lifted to 40~100 meters.

Improve product quality

Helps minimize product damage and contamination during shipping, improving product quality and reducing waste.

No dust or material

Fully sealed structure, the inner edge of the bearing is sealed with glue to the sealing ring, which is dustproof, weatherproof, and can also prevent material leakage during transportation.

Customizable

Can be customized to meet the specific needs of a production line, including bucket size and capacity, elevator speed, and type of material being conveyed.

Low maintenance cost

Typically low maintenance, with few moving parts and simple design. This helps reduce downtime and maintenance costs.

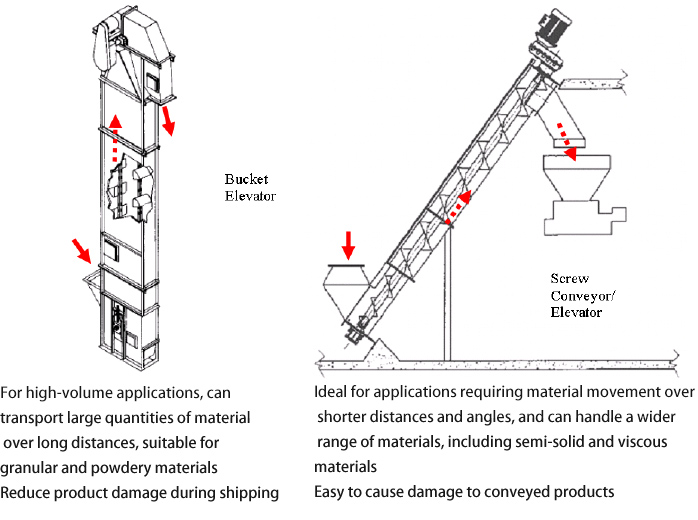

Both bucket elevators and screw conveyors are commonly used in material handling applications, the following are the differences between the two types of conveying equipment:

1. Conveying products: Bucket elevators are designed to transport materials vertically, while screw conveyors are designed to transport materials horizontally or inclined. Bucket elevators are ideal for applications where material needs to be moved between different levels of the production line, while screw conveyors are better for applications where material needs to be moved over shorter distances and angles.

2. Capacity: The bucket elevator has a higher capacity than the screw conveyor, and can handle larger volumes of materials over longer distances. This makes them a more efficient way of moving bulk materials.

3. Reduced product damage: Bucket elevators are designed to minimize product damage during transport because the buckets are gentle on the material being transported. And screw conveyors can cause more damage to some materials, especially if they are abrasive or brittle.

4. Maintenance: Bucket elevators require less maintenance than screw conveyors because they have fewer moving parts and a simpler design. This helps reduce downtime and maintenance costs.

bucket elavator for sand

chain elavator for fertilizer

Vertical-horizontal-vertical combined conveying

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

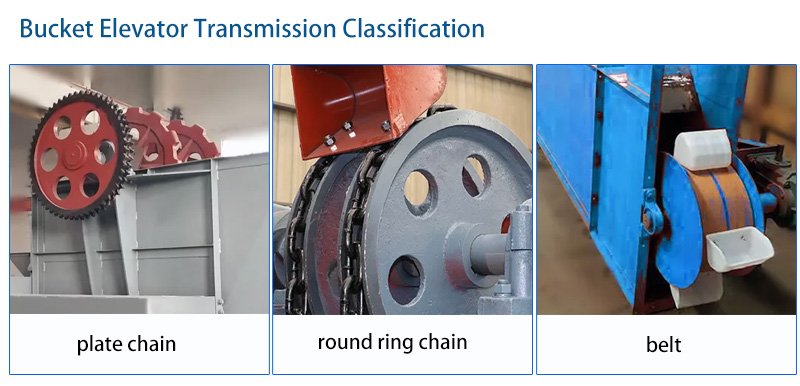

Traction parts: There are two types of tape (cotton core rubber belt/nylon core tape/steel rope core tape) and chain (plate type/ring type).

Hopper: punched and welded steel plate, divided into plastic bucket, nylon bucket.

Note: The bucket spacing is generally 2.5-3.5 times the bucket depth, about 200-400mm.

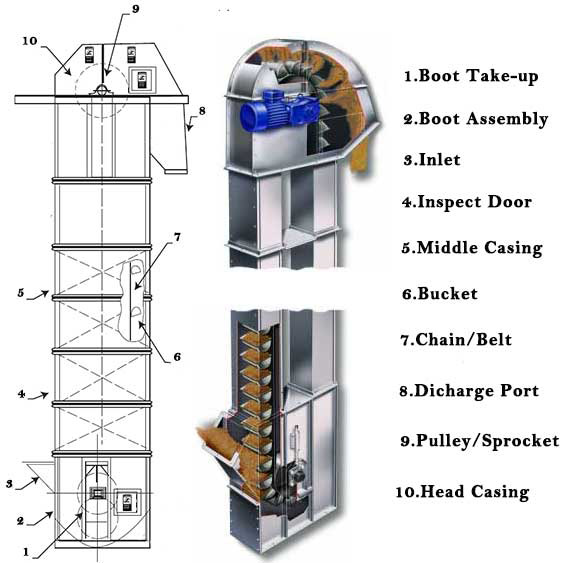

Machine head: It is composed of head wheel, machine head shell, discharge port and transmission device.

Base: base shell, bottom wheel, tensioning device, feeding hopper, deviation and speed sensing device.

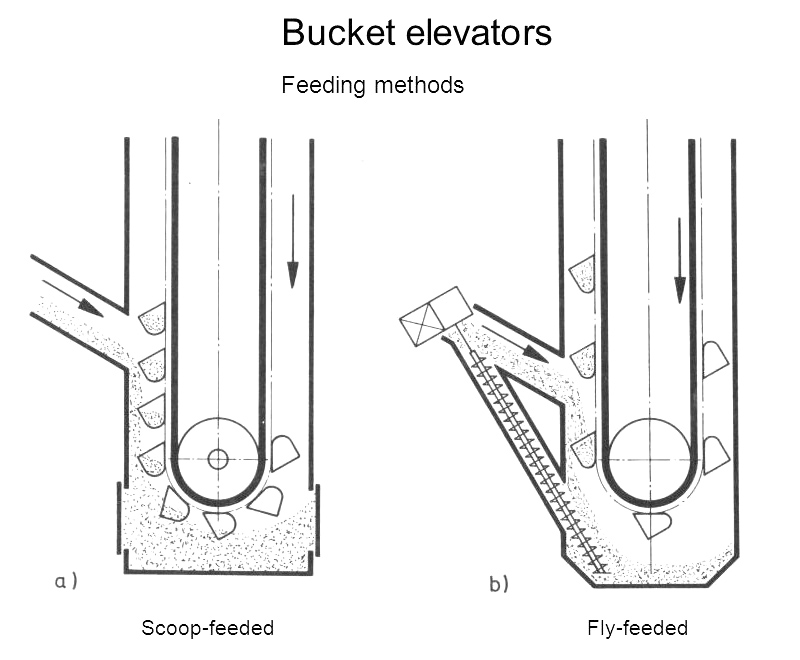

1. Loading method

(1) Take out

The material is drawn from the material by the hopper. The working resistance is required to be small, so it is mainly used to lift powdery and small bulk materials with less abrasiveness. The running speed of the hopper can reach 0.8-2m/s.

(2) Inflow type

The material flows directly into the hopper for filling. In order to prevent material spilling during loading, the hoppers of the bucket elevator are arranged in close contact. It is mainly used to lift bulky and abrasive materials. The running speed of the hopper shall not exceed 1m/s.

2. Unloading method

(1) centrifugal

The running speed of the hopper is usually 1-2m/s. The value of the centrifugal force on the material is greater than the gravity value, and the material in the hopper moves along the outside of the inner wall of the hopper for centrifugal discharge. It is used for unloading of powdery, granular and small block materials that are easy to flow.

(2) Gravity type

The running speed of the hopper is about 0.4-0.8m/s. The gravity of the material is greater than the centrifugal force, and the material moves along the inner wall of the bucket elevator hopper for gravity discharge. It is used for unloading bulky and abrasive materials. It is required to use a scale hopper, and the hoppers are arranged in close contact.

(3) Centrifugal + gravity (mixed)

The running speed of the hopper is about 0.6-0.8m/s. - Part of the material moves along the outer side of the inner wall of the hopper under the action of centrifugal force, and another part of the material moves along the inner side of the inner wall of the bucket elevator hopper under the action of gravity, which is suitable for poor fluidity and wet materials. The hopper generally chooses a shallow hopper, and the distribution method is an interval layout to ensure the completion of unloading. This unloading method combines the advantages of centrifugal and gravity elevators, and is suitable for the transportation and lifting of most materials.

Bucket elevators are available in a variety of designs and options to meet the specific needs of your production line. Here are some of the options available for bucket elevators:

1. Bucket material: Buckets can be made of various materials, including steel, plastic or aluminum, depending on the material being transported and the environment in which the elevator will be used.

2. Bucket size and shape: The size and shape of the bucket can be customized to optimize the transportation of specific materials, such as powders or granules.

3. Traction parts: The bucket elevator can use rubber belts, steel cable belts or chains to move the bucket. The choice of belt type will depend on the specific requirements of the application.

4. Bucket elevator configurations: Bucket elevators can be designed in a variety of configurations, including single-point or multi-point discharge, vertical or inclined transport, and straight or Z-shaped configurations.

Bucket elevators are widely used in industries and applications that require the vertical transportation of bulk materials between different levels of a production line. Here are some common applications for bucket elevators:

1. Agriculture: Commonly used in the agricultural industry to transport grain, seeds and other bulk materials between different stages of the production process.

2. Mining industry: It is used in the mining industry to transport coal, ore, minerals and other materials from underground mines to the surface.

3. Food processing: Used in food processing facilities to convey grain, flour, sugar and other food products between different stages of the production process.

4. Chemical processing: used in the chemical processing industry to transport materials such as fertilizers, plastics and other chemicals between different stages of the production process.

5. Construction: Used to transport materials such as cement, sand and gravel between different floors on a construction site.

6. Power plant: used in power plants to transport materials such as coal and biomass from storage bins to boilers as fuel.

7. Recycling: Used in recycling plants to transport materials such as plastic, glass and metal between different stages of the recycling process.

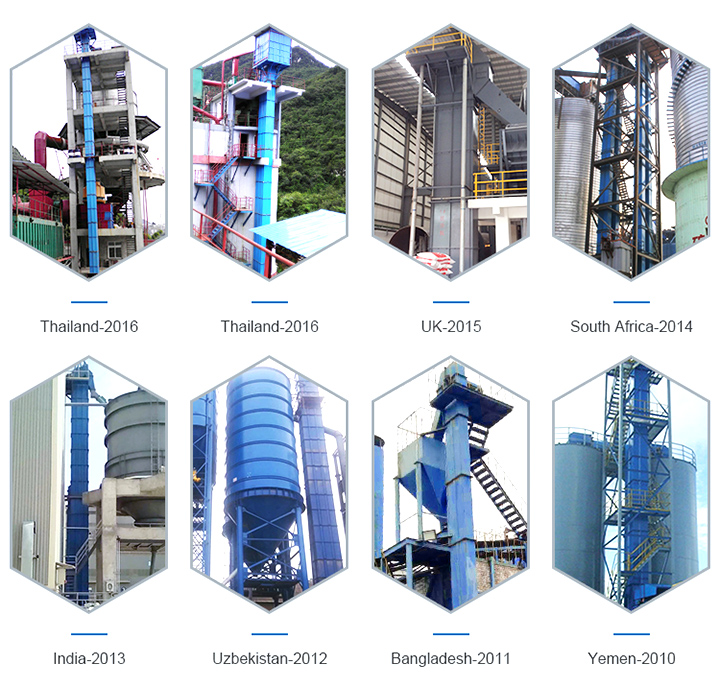

Dahan bucket elevator manufacturers include design, drawing, modeling, processing, quality inspection, assembly, test machine, painting, delivery, etc. We have machining workshops (lathes, milling machines, boring machines, drilling machines), assembly workshops, painting workshops, warehouses, etc. 13 years of production experience, complete models, reasonable price, 1 year warranty, customized quick model selection, provide drawing parameters.

Xinxiang Dahan bucket elevator manufacturer has 15 years of production experience. It is a manufacturer and exporter of bulk material handling and conveying systems. The product manufacturing meets strict quality standards and has obtained ISO international quality system certification and EU CE certification. As a formal direct-selling bucket elevator manufacturer, we have a complete mechanical processing production line, and can customize different models, materials, configurations or designs according to the actual application of the user according to the characteristics, capacity and lifting height of the material.

We have a dedicated person responsible for tracking each order to deliver on time. Our products can be shipped within 24 hours (customized products are shipped within 7 days), which reduces waste and unnecessary steps in the production of products or services. Users gain more time. Dahan manufacturers can quickly and timely respond to the needs of users. If the equipment fails, we can immediately provide replacement parts. If necessary, we can dispatch technicians to the user's site within 72 hours to provide solutions.

Traction member: According to the material temperature, humidity, viscosity, particle size, loose density, and abrasiveness, there are three types of plate chain type, ring chain type, and belt type.

Overall height of equipment: Determine the lifting height according to the customer's actual foundation conditions and lifting requirements, and then determine its total height (the total height is the lifting height plus the height of the head and base)

Drive device: Y series motor + reducer with backstop (motor power over 18.5KW, hydraulic coupling is required)

Bucket speed: The bucket speed of high-temperature materials and abrasive materials is less than 0.3m/s, and the bucket speed of cohesive materials is 0.5~1.2m/s.

Bucket capacity: Calculated by the horizontal bucket capacity, generally take 0.75%~0.85% of the horizontal bucket capacity to calculate the lifting amount during work.

Q: What's material will be transported by Bucket elevator ?

A: Bucket elevator is a kind of conveying equipment used for conveying bulk materials vertically,like cement, sand, limestone and grain etc.

Q: What's capacity of Bucket elevator that you want?

A: 20t/h, 50t/h and 100t/h etc.

Q: How high is the Bucket elevator ?

A: 10m, 30m and 50m etc.

Q: Other speical require?

A: Dahan bucket elevator manufacturers select and design according to the parameters you provide. We have 13 years of experience in design and production, and the product quality is good.Like hot material, SEW gearbox and Siemens motor etc.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.