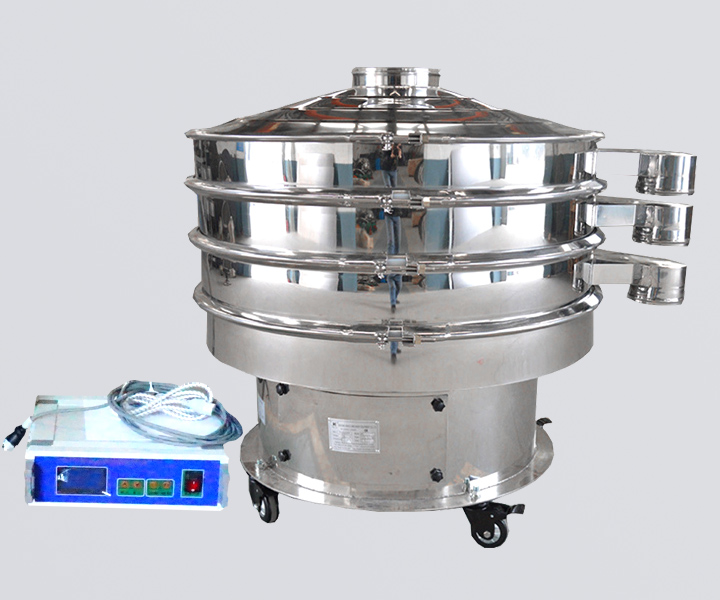

ultrasonic vibrating screen

ultrasonic vibrating screen stainless steel ultrasonic vibrating screen

stainless steel ultrasonic vibrating screen multi-layer ultrasonic vibrating screen

multi-layer ultrasonic vibrating screen movable ultrasonic vibrating screen

movable ultrasonic vibrating screen mobile ultrasonic vibrating screen

mobile ultrasonic vibrating screen

For ultrafine powder screening, prevent mesh blinding and blocking with ultrasonic system

![]()

![]()

![]()

Price:$800.00-$3,000.00/Set

Consult now and enjoy a 10% discount

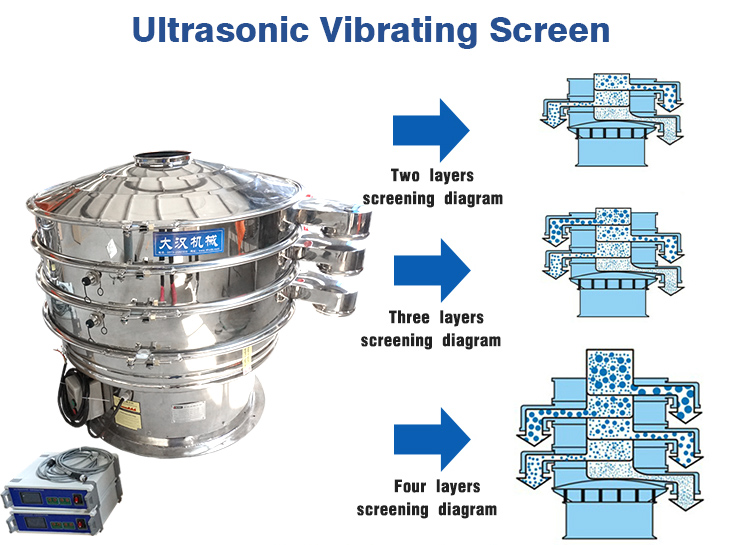

Mesh Size: 10-635 Capacity:1-20t/hLayer:1~5 layers

Material: Stainless steel 304,316L,or Carbon Steel

Voltage: 3 phase, 220V/ 380V/ 415V, 50HZ/60HZ(Customized is available)

Application:Strong adsorption, adhesion, sticky, high static, high density, ultrafine powder, etc.

Customizable: external type/built-in type, gate type, gas protection type

Commitment:

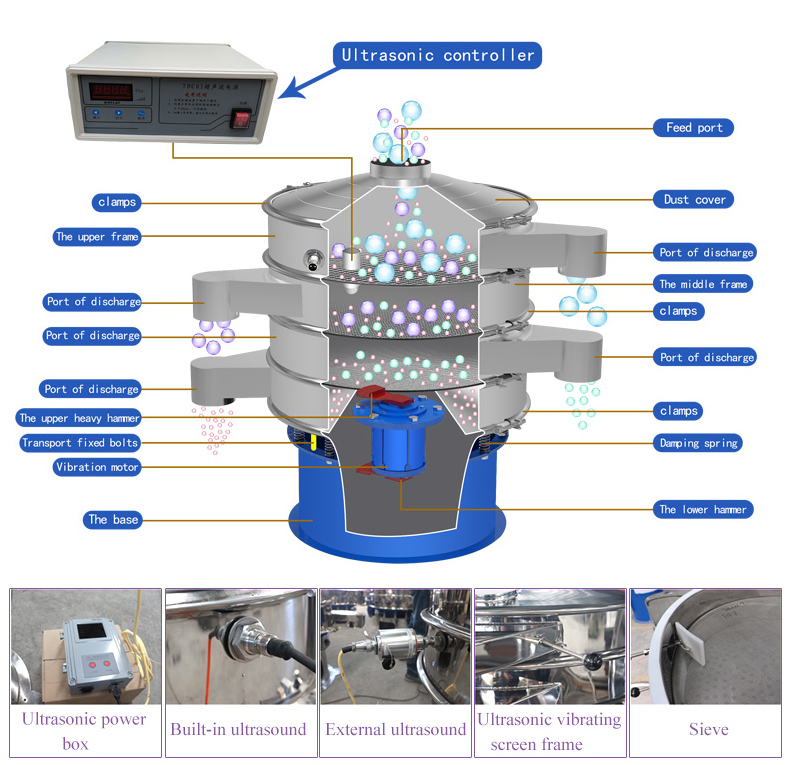

Ultrasonic vibrating screen is an additional ultrasonic system on the basis of ordinary vibrating screen,it consists of consisting of a generator and a probe that applies an ultrasonic frequency to a mesh screen,it has been designed to allow for difficult powders to be easily screened on sieve meshes. Not only does this increase the capacity of the product that is sieved but allows for accurate separation down to 20µm (#635mesh)。Screening accuracy can be increased more than 80%, capacity increased by 2 to 5 times.

Ultrasonic vibrating screen also be called as other name in different country, for example, sometimes will also named it as Ultrasonic Sieve; ultrasonic vibro sifter; ultra-sonic vibrating separator and so on.

Note: Our ultrasonic vibrating screen adopts a gate design, and the operator can decide the material screening time by himself.

1. Ultrafine powder screening: Really solve the screening problems of the characteristics material of strong adsorption, adhesion, sticky, high static, high density, ultrafine powder, etc.

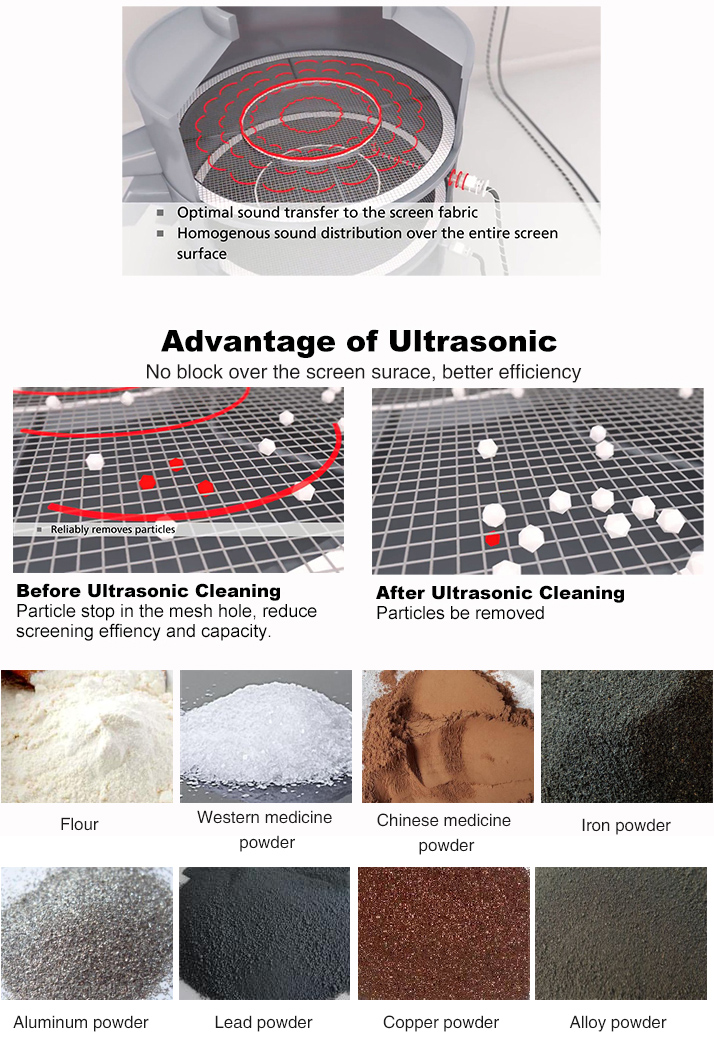

2. Solve the network blockage: convert 220V, 50Hz electric energy into 38KHz high frequency electric energy, input the ultrasonic transducer, and turn it into 38KHz mechanical vibration, so as to achieve the purpose of screening and cleaning the network, making it easy to screen fine powder Increasing the penetration rate and reducing the clogging of the screen.

3. Reduced costs: eliminates mesh damage normally associated with mechanical cleaning devices, increasing mesh life

Suitable for Ultra-fine Powder

Solved the problem of the sieving of strong adsorption, free huddle, strong stickiness, high static, high density, ultrafine powder, etc.

Not Clog the Mesh

The vibration frequency of the ultrasonic vibrating screen is 360,000 times/minute, which effectively prevents the screen from clogging, and the materials that are difficult to screen hardly block the mesh.

Improve Efficiency

The accuracy of the sieve can be increased by more than 80% and the output is increased by 2-5 times.

Lower Cost

There is no need to add a screen cleaning device, except for the damage of the mesh usually associated with mechanical cleaning equipment, and increase the service life of the mesh.

Ultrasonic vibrating screen can input 220V, 50Hz or 110V, 60Hz electric energy into the ultrasonic transducer, and turn it into 36KHz mechanical vibration. Ultrasonic vibrating screen can input 220V, 50Hz or 110V, 60Hz electric energy into the ultrasonic transducer, and turn it into 36KHz mechanical vibration. The generated ultrasonic wave makes the screen mesh vibrate at a high frequency. The materials on the screen surface are superimposed with ultrasonic vibration while performing low-frequency rotational vibration, which can not only prevent mesh clogging, but also improve the output and product quality of the screening machine, making the ultrasonic vibrating screen easy to screen ultrafine powder.

Ultrasonic Vibrating Screen for Calcium Powder

Ultrasonic Vibrating Screen for Fine Powder

Ultrasonic Vibrating Screen for Bentonite

Ultrasonic system can improve screening efficiency by 50%-400%.

| Model (mm) |

Testing materials | Ordinary screening machine | UItrasonic vibrating screen | ||

| Mesh | Test results | Mesh | Test results | ||

| φ1000 | Silicon carbide | 500 | Unable to screening | 500 | 1500KG/H |

| Tungsten powder of cemented carbide | 600 | No fine powder was sifted out for 15 minutes | 600 | 30KG/H | |

| vitamin c powder | 400 | 1KG/H | 400 | 120-150KG/H | |

| φ500 | Pollen | 400 | No fine powder was sifted out for 15 minutes | 400 | Screen out 20% in 15 minutes.Fine and effective classification can be carried out in fine workmanship. |

| Nickel powder,Cobalt powder | 325 | Screen three times to meet the requirements | 400 | Screen once to meet the requirements | |

| φ450 | Ndfeb powder | 300 | 32.2% residual sieve in 30 minutes | 300 | 6.9%residual sieve in 30 minutes |

1、Ultrasonic resonance power supply: 38KHz high-frequency high-power ultrasonic resonance power supply. The built-in microcomputer chip can automatically track the whole digital frequency according to the different states of the ultrasound, without manual adjustment, and the operation is simple and convenient. Long-time working oscillator has low heat output and stable working condition.

2、High-frequency connection line: The ultrasonic oscillator and the ultrasonic resonant power supply are connected by a cable.

3、Connector: Aviation connection plug-in.

4、Oscillator: High-performance ultrasonic conversion device.

5、Ultrasonic grid: It is composed of an outer grid and a resonance ring.

6、Ultrasonic vibrating screen: suitable for 10 mesh to 635 mesh.

| Model | Effective screening diameter | Screen mesh size range | No of layers | Power | Online quotation |

| DHC-400 | 340 | 80-600MESH | 1-3 LAYERS | 0.18KW |  |

| DHC-600 | 540 | 80-600MESH | 1-3 LAYERS | 0.25KW |  |

| DHC-800 | 730 | 80-600MESH | 1-3 LAYERS | 0.55KW |  |

| DHC-1000 | 900 | 80-600MESH | 1-3 LAYERS | 0.75KW |  |

| DHC-1200 | 1100 | 80-600MESH | 1-3 LAYERS | 1.1KW |  |

| DHC-1500 | 1400 | 80-600MESH | 1-3 LAYERS | 1.5KW |  |

| DHC-1800 | 1700 | 80-600MESH | 1-3 LAYERS | 2.2KW |  |

| Special Design | Features | Photo |

| Edged type | The specially designed flanged type increases the feeding amount, prevents the material from splashing, and is easy to observe the mesh. |  |

| Gate type | There is a gate-type design for the treatment of special materials to extend the screening time of difficult-to-screen materials and increase the processing capacity. |  |

| Explosion-proof | The whole machine has better sealing performance and adopts BZDL explosion-proof vertical vibration motor to meet the higher requirements of special industries. |  |

| Airtight type | Install a gas protection device to ensure that the new material does not touch the air during the screening process and overcome dust pollution |  |

Test video for fine powder

Installation steps of ultrasonic vibrating screen

Ultrasonic vibrating screen mesh replacement

Ultrasonic vibrating screen is suitable for powdered sugar, starch, salt, soybean milk powder, API intermediates, silicon carbide, brown corundum, white corundum, molybdenum powder, tungsten powder, nickel powder, cobalt powder, stainless steel powder, alloy powder, powder coating, Quartz powder, emery, electromagnetic powder, laser powder, aluminum powder, electrolytic copper powder, grinding powder, refractory material, luminous powder, glass microbeads, rubber additives, etc.

1.Size classification:separation of particles into groups of comparable size from the materials.

2.Gravity filtering:removal of solids from liquids and slurries.

3.Product reclamation:removal of the solids from waste product or clarification of waste liquor for further use.

4.Screening:separation of a few oversize particles from a quantity of materials.

Dahan Machinery is an ultrasonic vibrating screen manufacturer integrating R&D, production and sales. It has been 14 years since our establishment. The manufacturer has obtained ISO9001 and EU CE certification, and has successfully served users in more than 80 countries and regions around the world. Dahan ultrasonic vibrating screen can be made of carbon steel and stainless steel according to the screening materials. The models are complete, and non-standard designs can be customized according to user requirements. The product will be shipped within 24 hours after being assembled, and if there is a performance problem within 30 days after the user signs it, it can be returned for free. It provides 1-year warranty, lifetime maintenance, original supply of product accessories and other services.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.