ISO/CE 30 Days Free Return Shipped in 5 Days 1 Year Warranty

Screen Mesh: 10 mm - 400 mesh (38 microns)

Width: 500-1500mm

Length: 2000-4000mm

Capacity: 10Kg-10Tons/Hour

Layer(s): 1-6 Layers

Motor Power: 2*(0.4-3.7)kw(Ordinary type or explosion-proof type optional)

Deck inclination: 0-15°

Applications: suitable for inspection, screening and grading of fragile materials with low bulk density, such as rice, corn, wheat bran, feed, abrasives, quartz sand, plastic granules, stones, etc.

Multi-layer Horizontal Screening Machine Which Allows the Materials to Screen and Grade Accurately.

Linear vibrating screen, also known as linear motion vibrating screen, the motion is linear, used for screening, classifying, deblocking, dewatering any lumpy solids or slurries, it uses a vibrating motor to throw up and forward linear motion Materials, these models are usually run with dual vibration motors that operate in synchrony, centrifugal force and gravity help throw the material in the direction it's moving, multi-layer systems can separate the product into 2-7 different parts, in Multi-stage separation is completed while removing impurities.

Linear vibrating screen can provide 500mm to 1,500mm wide and 1,500 to 4,000mm long screening area, allowing up to 20 tons / hour of processing capacity, suitable for a variety of dry 0.074-5mm particle size, moisture content less than 70%, non-sticky For the screening of powdery materials, the maximum feeding particle size is not more than 10mm.

Linear vibrating screens have the ability to convey while separating and are often used for container filling and safety screening – preventing clumping, oversized products or large particles that could cause problems in subsequent processing or quality control, while maintaining optimum performance for further processing. feed rate. Another common application is to combine a hopper with a screen - unloading material from the hopper, removing fines and feeding the material to the inspection table, improving inspection efficiency. It can be equipped with single-layer or multi-layer screens, and can continuously screen up to 7 products at a time.

Successfully used for:

Coarse grading - grading bulk materials that do not require extreme dimensional accuracy

Fine Classification - Provides high precision for particle sizes from less than 3 mm to 50 microns

Dust removal - for extraction of undersized particles

Protective Screening - Used to remove oversized particles, impurities and other foreign bodies, etc.

Separation - remove coarse material from fine material

Dewatering - used to recover solids from wash media

Extraction - Used to remove insoluble impurities from washing and carrier liquids.

The linear vibrating screen relies on two reverse motors of the same frequency to make the material jump straight forward on the screen surface. After a large number of broken materials with different particle sizes and mixed thickness enter the screen surface, only a part of the particles contact the screen surface. The vibration of the box loosens the material layer on the sieve, which further expands the existing gap of the large particles, and the small particles take the opportunity to pass through the gap and transfer to the lower layer. Due to the small gap between the small particles, the large particles cannot pass through, so the original is disorderly. The arranged particle groups are separated, that is, stratified according to the particle size, forming an arrangement rule that the small particles are at the bottom and the coarse particles are at the top, so as to achieve the purpose of screening and sorting materials.

Rough cleaning and screening

It is suitable for sieving any dry material of 0.74mm-5mm, the maximum particle size is 10mm, and the sieving accuracy reaches 200 mesh (0.074mm).

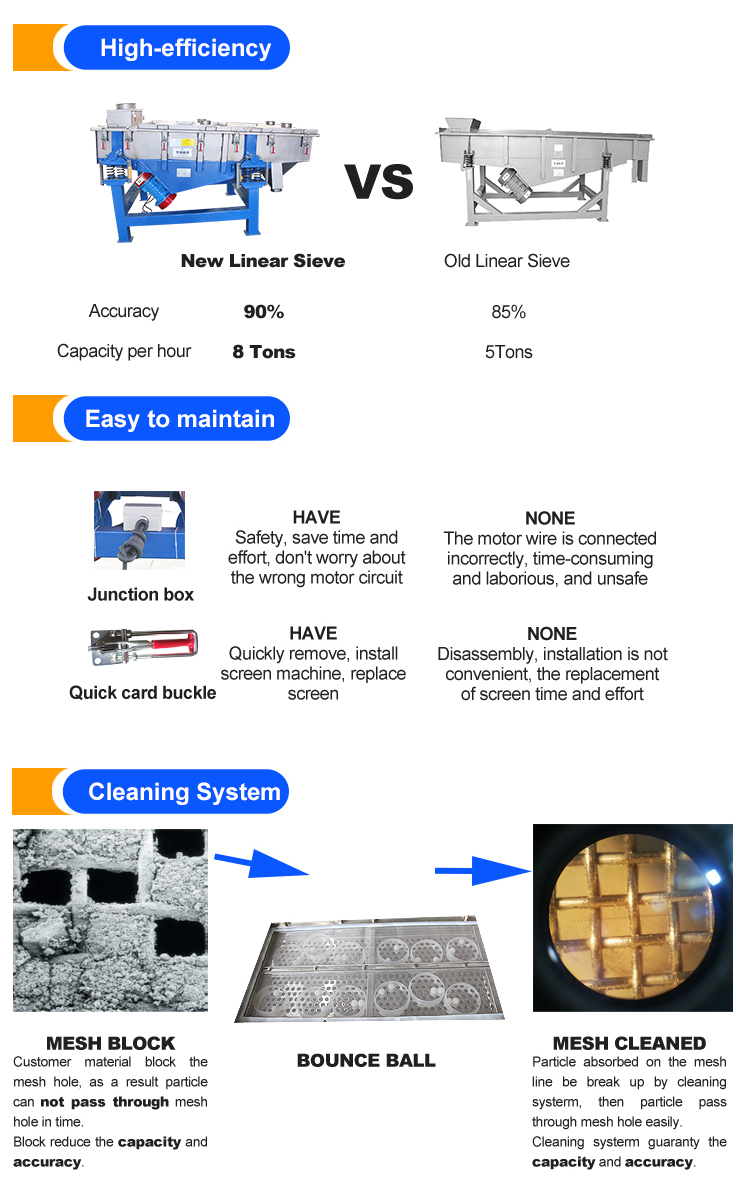

High capacity

Impurities and coarse materials are automatically discharged, continuous operation, it can process 0.12-20 tons/hour per hour.

Dual motor

Equipped with vertically mounted dual motors for proper vibratory flow, the screening efficiency is up to 96% and the energy consumption is reduced by 30%.

Multi-layer separation

The multi-layer system can classify products into 2, 3, 4, 5, 6 or 7 different grades as it can build up to 6 layers.

closed system

Fully enclosed structure, good sealing, less dust flying, can also be enclosed or connected to the air duct dust collector.

Screens are easy to clean and replace

Equipped with a simple clamping system that allows the operator to easily clean the screen when needed.

Screening plastic particles

Linear vibrating screen with belt conveyor

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Selection tips:

1. The shape and size of the sieve hole: the particle size of the circular sieve is smaller, and the size of the square sieve is larger.

2. The length and width of the screen surface: the model is determined by the length and width of the screen surface of the sieve (such as a 1025 type sieve, representing 1000mm (width) x 2500mm (length)), the wider the screen surface width, the thinner the material layer thickness will be , the greater the output, the longer the length of the screen surface, the longer the screening time, the more chances of sieving, and the higher the screening efficiency. Generally, the appropriate width-to-length ratio is 1:2~1:3.

3. Screen surface inclination: In general, linear vibrating screens can be installed at a certain angle. If the inclination is too small, the material movement speed will be slow and the productivity will be greatly reduced. If the inclination is too large, the discharge will be too fast and the screening efficiency will be reduced. , so the inclination angle should be appropriate. Generally, we suggest that the inclination angle of the linear vibrating screen is 0-15°. If special materials are to be screened, the inclination angle can be increased appropriately, but it should not exceed 25°.

4. Motor excitation force: must be higher than 30% of the total weight of the linear screen.

Xinxiang Dahan linear vibrating screen manufacturer has independent research and development capabilities. Our linear vibrating screen can be customized according to user needs and actual application conditions, such as adding a feeding device, movable type, heightened base, etc.,

The distance between the discharge port of the standard linear vibrating screen and the ground is 500mm, and the total height of the equipment, the height of the discharge port from the ground, and the height of the support from the ground can also be designed according to the actual situation of the use occasion.

| Name | Image | Features |

| Ordinary linear vibrating screen |  |

Suitable for handling a wide range of dry powders and granules |

| Air-cooled linear vibrating screen |  |

It is suitable for high temperature materials and can be screened after effectively reducing the temperature of the materials. |

| Adjustable Linear Vibrating Screen |  |

Adjust the angle and height of the linear vibrating screen according to the material screening process. |

| Suspended linear vibrating screen |  |

The screening equipment that can be installed in the air can save space on the screening site |

| Silo type linear vibrating screen |  |

Equipped with a feeding bin, the feeding speed can be controlled by adjusting the feeding bin insert. |

In order to make it more convenient for you, you can compare the following table to clear your machine configuration

(You can also click this link to contact us directly)

| General requirements | Model | DZSF-520/525/530/1020/1025/1030 |

| Number of Layers(L) | 1-6(Suggest ≤ 3) | |

| Main Material | Stainless Steel(304/316L)•Carbon Steel(Q235)•PP | |

| Number of vibrations(times/min) | 960 | |

| Sealing Strip | Silica gel / Rubber | |

| Special requirements | Overall height of the fuselage | Please communicate specifically |

| Feed inlet | Angle / Size and so on | |

| Outlet | Angle / Size /Add valve | |

| Observation port | Silicone cover / Rubber cover / Glass cover | |

| spring | You can choose whether to add a silicone protective cover | |

| Internal spray(mm) | PTFE / ePTFE / WC / Al2O3 | |

| Equipment surface treatment | Polishing / Sandblasting | |

| Body metal material requirements | For example: require no Cu and Zn (except electrical parts) | |

| Vibration motor | Ordinary motor / Explosion-proof motor | |

| other | Customized to your needs |

Show Details

Installation Steps

Grid Installation

Motor Installation

The linear vibrating screen can be designed and customized according to the actual use requirements, such as the installation position of the vibrating motor, the type of screen, adding a batcher at the feed inlet, the feed inlet can be designed as a circle or square according to the relevant configuration pipeline, the shape, size and outlet The height of the feed port can also be customized according to actual use requirements.

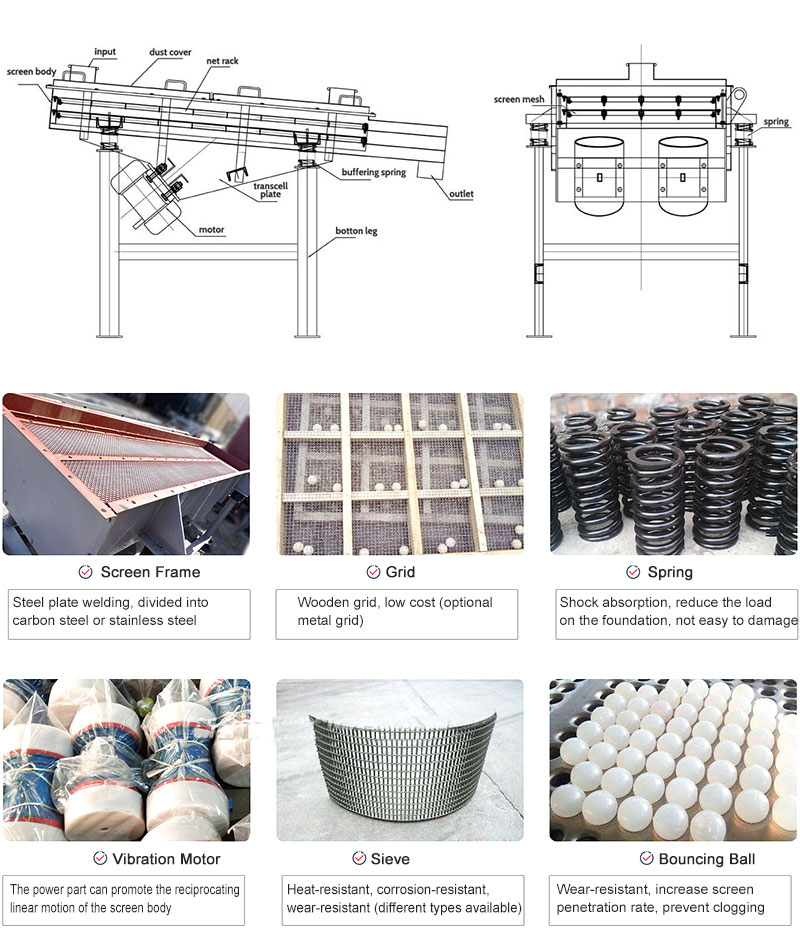

Motor installation position

The vibration motors are installed on both sides of the linear vibrating screen: it is suitable for occasions where the overall height of the equipment is limited, but the width of the equipment is not limited. For example, due to the special requirements of some materials, the discharge port of the equipment cannot be too high. If the vibration motor is also installed at the bottom of the linear vibrating screen, the overall height of the equipment cannot be well controlled.

The vibration motors are installed at the bottom of the linear vibrating screen: the motor is installed at the bottom of the equipment, which reduces the overall width of the linear screen, thus ensuring the shielding area of the equipment without affecting the throughput and shielding efficiency.

The vibration motors are installed on the top of the linear vibrating screen: If the height and width of the outlet of the customer's linear screen equipment are limited, no matter whether it is installed at the bottom or on both sides, the vibration motor cannot meet the requirements. At this time, the vibration motor can be installed in the middle of the top of the equipment, which will neither increase the width of the equipment nor affect the height of the discharge port of the equipment.

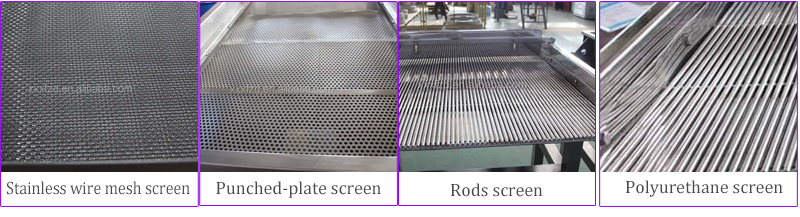

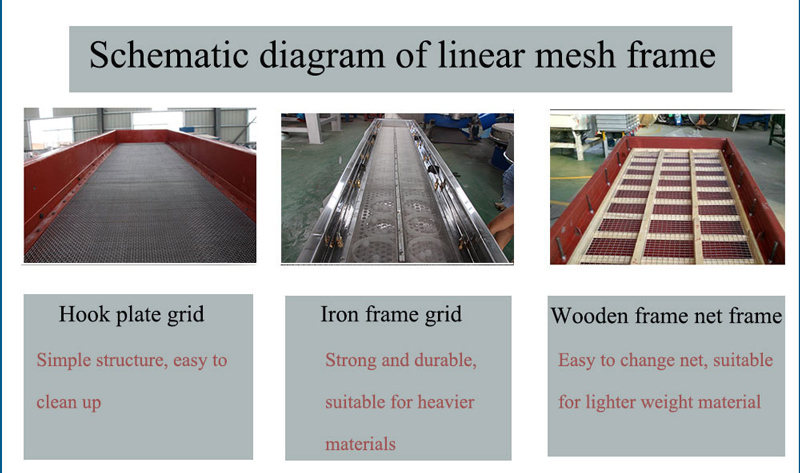

Different Types of Screen

Linear vibrating screen can provide different screen types to achieve different screening goals.

The types of screens that can be included are:

1.Woven wire mesh

2.Laser cutting of punched plates

3.Wedge

4.Grid bars

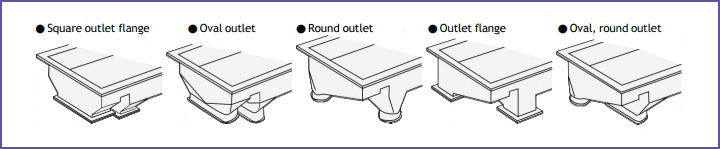

Different Outlet Design

The discharge port of the linear vibrating screen can be round or square, and the direction of the discharge port can also be designed according to needs, such as left, right, downward, and forward.

Frames of Different Materials

There are two main types of linear vibrating screen mesh frames: wooden mesh frame and iron mesh frame. So which mesh frame should customers choose when purchasing linear screen equipment? First of all, let's have a simple understanding of these two mesh frames.

1. Wooden mesh frame: It mainly uses high-quality poplar, red pine and white pine as raw materials. Net cleaning devices such as bouncing balls can be added to increase the net penetration rate, which can prevent the clogging of the linear vibrating screen. It is very suitable for granular, powdered sieving of materials.

2. Metal grid: The material can be divided into Q235 carbon steel and 304 stainless steel. The metal mesh frame is mainly made of Q235 carbon steel or 304 stainless steel as raw materials. The screen is strong and durable, and can ensure the screening quality of materials. It can be used to screen large particles and materials with heavy specific gravity.

| Material | Proportion | Mesh | Model | Method | Processing Capacity Kg/h |

| Millet | 0.15 | 250 mesh | DZSF-515-2s | Dry | 600 |

| Quartz Sand | 1.6 | 70 mesh | DZSF-1540-3s | Wet | 30000 |

| Raisin | 0.83 | 60 mesh | DZSF-520-1s | Wet | 6000 |

| Sunflower Seeds | 0.04 | 80 mesh | DZSF-525-1s | Dry | 7100 |

| Plastic Particles | 0.95 | 3 mm | DZSF-515-2s | Dry | 500 |

| Flour | 0.6 | 24 mesh | DH-515-3S | Dry | 1500 |

| Iron ore Powder | 2.3 | 150 mesh | DZSF-1020-3s | Dry | 10000 |

| Slag | 4 | 5 mm | DZSF-1020-1s | Dry | 10000 |

| Sawdust | 0.2 | 80 mesh | DZSF-1030-3S | Dry | 18000 |

| Emery | 4 | 60 mesh | DZSF-515-1S | Dry | 300 |

| Wood Flour | 0.4 | 120 mesh | DZSF-1036-4s | Wet | 2000 |

| Activated Carbon | 0.8 | 36 mesh | DZSF-515-1s | Dry | 500 |

Xinxiang Dahan Vibration Machinery Co., Ltd. has a factory area of 10,000 square meters. It has been 15 years since its establishment. Our company has passed ISO and CE certification. machine or withdraw.

The models of linear vibrating screen include DZSF-520, DZSF-525, DZSF-530, DZSF-1020, DZSF-1025, DZSF-1030, etc. Carbon steel and stainless steel can be selected according to the characteristics of the screening material, and the screening purpose can also be selected. To choose 1~6 layers of screen mesh, if you have special requirements, we can also customize different configurations and designs according to the user's process requirements.

Dahan linear vibrating screen manufacturers provide design selection, test machine with material, 72-hour free door-to-door delivery, after-sales maintenance and other services, and 365-day quality assurance.

Q: What is the inclination angle of the linear vibrating screen?

A: Generally 0°~15° (the inclination angle can be increased according to special materials, not more than 25°)

Q: The linear vibrating screen generally chooses several layers for better effect?

A: The linear sieve can be separated in multiple stages. The 1-6 layers of the screen can screen 7 kinds of specifications. The size of the particles after screening is uniform, but it is generally recommended not to exceed 5 layers, and the number of layers is too much. The excitation force cannot transmit the force well.

Q: If the space is limited, how can I choose the right linear screen?

A: Our factory supports free of charge to develop the service of the production line for users, and at the same time, it can also be solved through tailor-made.

Q: How can I be sure that my product is suitable for this machine? How do I see results?

A: You can mail the material to our company, we will test it for you and send you the video for free.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.