The circular and tapping motion of the test sieve in manual sieving is accurately reproduced. When precise separation is required, uniform mechanical action ensures reliable, comparable dimensional testing.

![]()

![]()

Price:$650.00-$1,500.00/Set

Consult now and enjoy a 10% discount

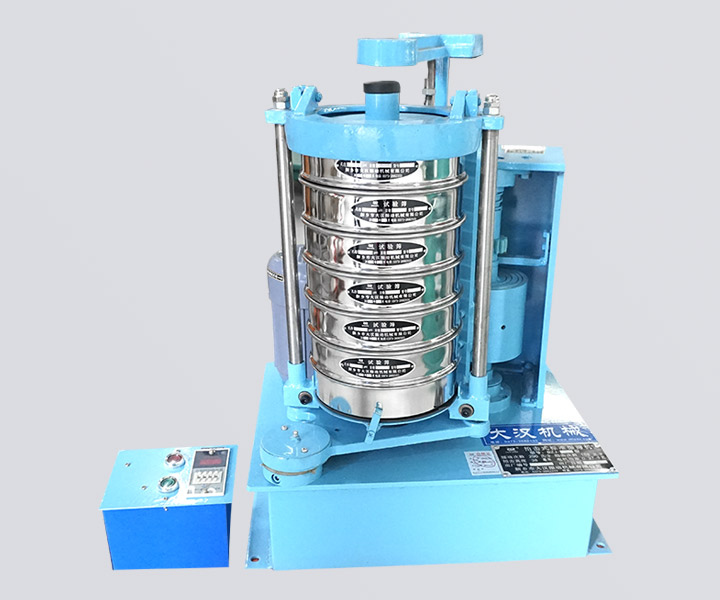

Model: 200mm/300mm

Slap times: 156±3 times/min Slap height: 38±6mm

Oscillation times: 290±6 times/min

Layers: 1-8 layers

Timer: 0-99 minutes Weight: 125kg

Application: General abrasive particle size composition inspection and superhard material production grading and particle size composition inspection

Commitment:

Rotap Sieve Shaker offers a compact design and aggressive sieving action. This shaker provides 290 vibrations and 156 taps per minute to create an effective sieving action that stratifies material particles and finds critical openings in the test medium, and offers a built-in 99-minute timer, the unit has up to Holds 7 sieves and additionally includes a catch tray.

The rotap sieve shaker can be adapted for testing with 200mm diameter test sieves and 300mm diameter test sieves, due to its circular and percussion motion, when precise separation is required, the uniform mechanical action ensures reliable and accurate dimensional testing, suitable for handling quantities up to 2 kg and measuring ranges from 5 μm to 63 mm.

Rotap sieve shaker has two unique reciprocating and beating vibrating screening methods. The feeding speed is fast and the material will not be blocked. It is used for the detection of the particle size composition of ordinary abrasives, the classification and particle size detection of superhard materials, and is especially suitable for diamond micropowder, super Hard material production and grading process The hard material industry is used repeatedly with high strength and high frequency. . The following are some specific applications of rotap sievei shaker:

1. Quality control: Widely used in quality control process to ensure that the particle size distribution of the product meets the required standards. This is especially important in industries such as pharmaceuticals, food processing and cosmetics, where particle size can affect the efficacy, quality and appearance of the final product.

2. Material science: used in material science research to analyze and classify the particle size distribution of powder, granules and other materials. This information can be used to optimize manufacturing processes, develop new materials and improve the quality of existing materials.

3. Geology: Used in geological research to analyze soil samples and classify the size distribution of particles in sedimentary rocks. This information can be used to study the history and formation of geological formations and identify potential mineral deposits.

4. Environmental science: Used in environmental science research to analyze the particle size distribution of airborne particles such as pollen, dust and pollutants. This information can be used to monitor air quality, study the impact of human activities on the environment, and develop strategies to mitigate environmental damage.

| Product | Mesh size | Product | Mesh size | Product | Mesh size |

| Cassia | 14 mesh | Buckwheat | 12 mesh | Tenebrio eggs | 12 mesh |

| Insect droppings | 30 mesh | Soybean | 4-5 mesh | Green beans | 10 mesh |

| Rice | 12-14 mesh | Rice flour | 30-40 mesh | Cornmeal | 30-40 mesh |

| Flour | 50-60 mesh | Cereals | 40-50 mesh | Sesame | 22-24 mesh |

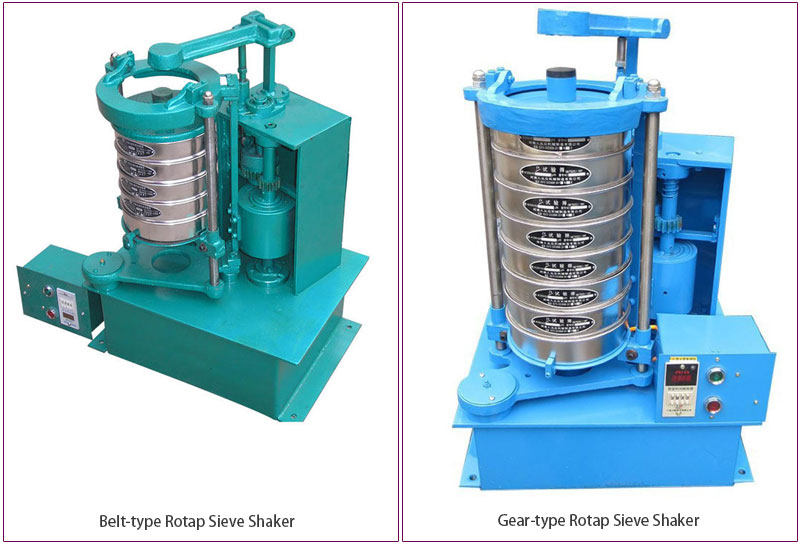

1. Different transmission modes

Belt-type Rotap Sieve Shaker: The belt-type rotap sieve shaker has carried out a reasonable innovation on the basis of the structure of the gear-type rotap sieve shaker, and improved the structure of the original machine base. The structure is more compact and simple, and the maintenance cost is low

Gear-type Rotap Sieve Shaker: The gear is used to drive the synchronous belt transmission, the speed ratio is accurate, and there will be no speed drop phenomenon of the general V-belt (3% drop rate of the V-belt), so that the sieving movement at the same time is consistent every time (The transmission ratio of the gear is 99.99% accurate).

2. Different designs

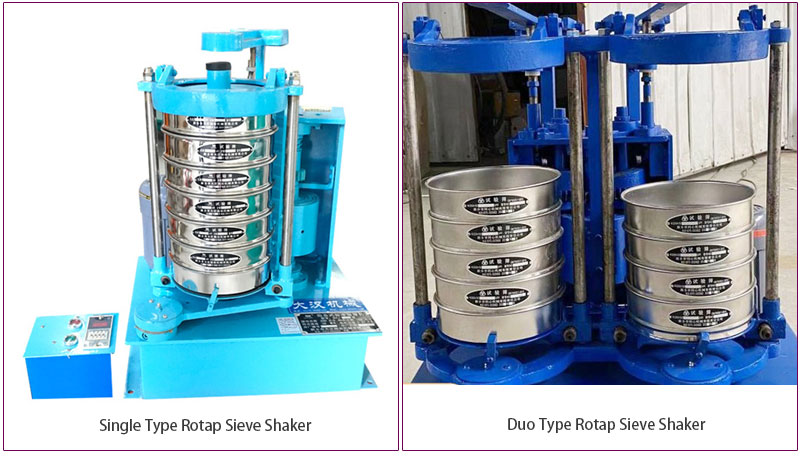

Single Type Rotap Sieve Shaker: 1 set of sieve frame is installed, only 1 material can be screened, and it can be divided into 1-7 different particle segments at the same time.

Duo Type Rotap Sieve Shaker: The unit also has a cavity to accommodate two stacks of 200mm/300mm diameter test sieves. This allows twice the processing power required to complete the test in the same amount of time.

| NO. | Name | Unit | Value |

| 1 | Sieve diameter | mm | φ200, φ100, φ75 |

| 2 | Sieve layer number | layer | 7 |

| 3 | 200 test samples | set | 1 |

| 4 | Rotation rate | times/min | 290±6 |

| 5 | Number of clicks | times/min | 156±3 |

| 6 | Click height | mm | 38±6 |

| 7 | Chassis levelness | mm/min | ≤0.6 |

| 8 | Rotate the track | mm | 25 |

| 9 | Electric machine | kilowatt | 0.37 |

| 10 | Shape size | mm | 433*432*785 |

| 11 | Screen machine weight | kilogram | 128 |

| 12 | CR control range | rpm | 0.001~1500 |

| 13 | CS control range | rpm | 10-7~1500 |

| 14 | Torque range | Nm | 2×10-8~0.2 |

| 15 | Frequency | Hz | 10-5~100 |

| 16 | Normal force | N | Minimum 0.01, maximum ±5 |

| 17 | Temperature control range | ℃ | -40~200 |

Rotap sieve shaker works by using a combination of rotary and tapping motion to separate particles by size. Here is a step-by-step overview of how the Rotap sieve shaker works:

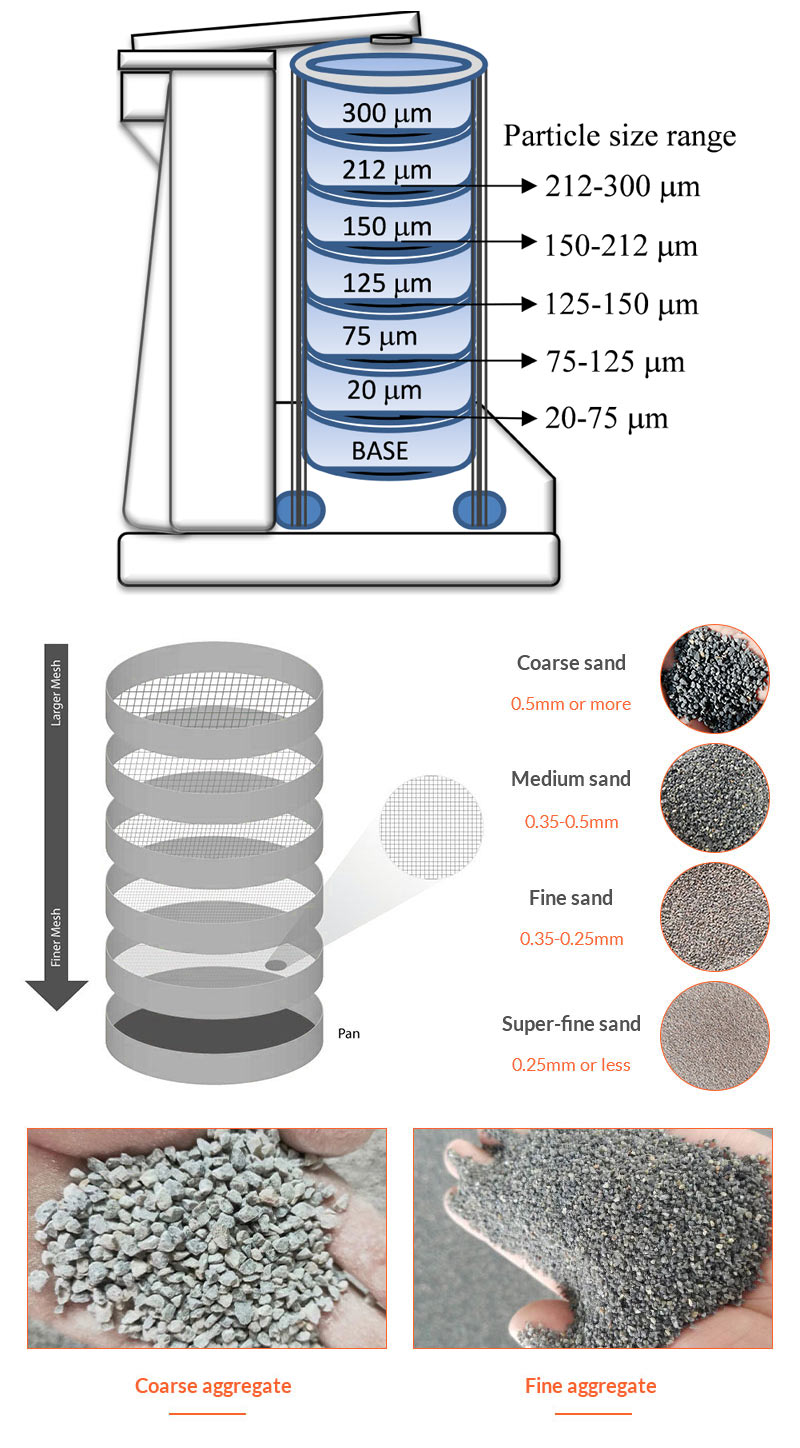

1. Preparation: The sieve trays are selected based on the desired particle size range to be analyzed. The sample to be analyzed is placed on the top sieve tray.

2. Assembly: The sieve trays are stacked on top of each other, with the largest mesh size on top and the smallest mesh size on the bottom. They are then secured to the vertical column.

3. Operation: The base of the shaker rotates in a circular motion, while the vertical column and sieve trays move up and down in a tapping motion. This motion causes the particles to move through the wire mesh of the sieve trays and separate into different sizes, with smaller particles passing through the smaller mesh openings and larger particles remaining on top of the sieve. The shaking motion is typically controlled by a timer.

4. Separation: After the shaking process is complete, the sieves are removed from the shaker and the particles that have passed through each sieve are collected and weighed. This allows for the determination of the particle size distribution of the sample.

Has a unique 2D operating mode

With a horizontal circular motion and vertical tapping motion, this method allows the particles to stratify and "search" for critical openings in the sieve, allowing easy screening of agglomerated bulk materials.

Automatic timing

Featuring a 99 minute digital timer/clock with a 0.1 second tolerance, it is designed to achieve consistent, repeatable results that are more reproducible than manual sieving.

Multi-layer filtering

It can accommodate 1 to 8 sieves (including sieve bottoms), and can continuously sort a sample with 7 different particle size segments.

Accurate speed

The gear-driven "synchronous belt" transmission method is adopted, and the transmission is accurate and consistent, and there will be no speed drop or belt slip phenomenon.

Save time

The time required to perform sieving analysis can be reduced, which not only allows you to perform and analyze results faster, but also allows you to complete more tests per day.

Durability/Lifespan

The contact adaptability between the step belt and the gear is good, the service life is long, the wear is not easy, the cost is low, and it is easy to replace. Reduced technical requirements and costs for maintenance.

Rotap Sieve Shaker for Metal Powder Inspection

Rotap sieve shaker for testing abrasives

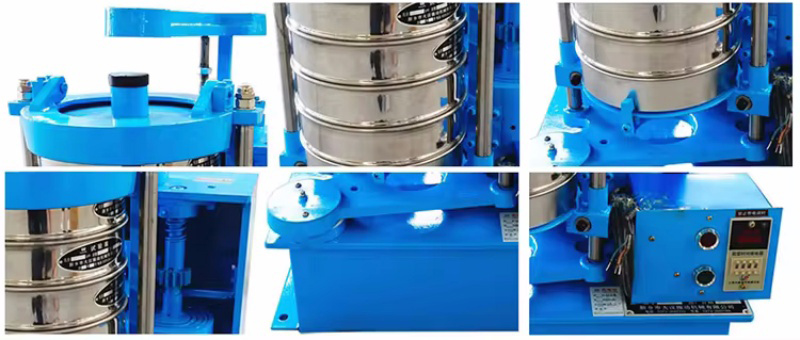

Beat hammer: The screen is vibrated by the vibration motor. During this process, the small beat hammer on the top keeps beating and beating the top cover, and the materials that are easily blocked will be dispersed during the vibration and beating and penetrate the screen smoothly, and it is not easy to be blocked.

Screen: There are two kinds of diameters: 200mm and 300mm. The screen types include wire woven mesh (mesh size 2.36-0.02mm), punching plate screen (mesh size 1mm-125mm), electroforming screen (mesh size 1mm-125mm) size 5μm-500μm).

Time relay: set the running time on the timer, it can be automatically shut down, the time can be adjusted from 1 to 99 minutes, and the vibrating screen time can be freely controlled to ensure test repeatability and inspection production consistency.

Transmission device: The transmission mode of the synchronous belt driven by gears, the speed ratio is accurate, the accuracy rate can reach 99.99%, and the phenomenon of speed drop will not occur, and the two gears of the slap screen have no direct contact, the degree of wear is small, and the service life is longer.

| NO. | 1 | 2 | 3 | 4 | 5 |

| Part Name | Big gear | Up and down eccentric wheel | Cam | Eccentric copper sleeve | Slider |

| Part Model | Φ200-30 | Φ200-31 | Φ200-32 | Φ200-33 | Φ200-8 |

The rotap sieve shaker is available with a wide range of options and accessories to enhance its functionality and customization. Here are some common options and accessories:

1. Digital timer: A digital timer can be added to control the vibration time and frequency more precisely.

2. Adjustable amplitude control: Some rotap sieve shakers have an adjustable amplitude control that allows you to customize the intensity of the shaking motion.

3. Soundproof enclosure: A soundproof enclosure can be added to reduce the noise level during operation, which is especially useful in laboratory environments where noise pollution is a concern.

4. Wet sieve kit: The wet sieve kit can be added to the rotap sieve shaker for wet sieving of samples. The kit usually includes a waterproof base and a drainage system to facilitate the wet sieving process.

5. Calibration Kit: Ensures accurate operation and reliable results. The kit usually includes a standard test sieve and a sample of known particle size distribution.

6. Different sieve tray sizes and materials: can be equipped with different sizes and types of sieve trays, depending on the application. Sieve pans can be made of stainless steel, brass or nylon and can be designed for different particle size ranges.

Test product: Abrasive

Mesh size: 20 mesh -200 mesh

Recommended product: BZJ-200 Rotap Sieve Shaker

Test product: sand and gravel aggregate

Mesh size: 6mm, 8mm

Recommended product: Geared RO-TAP Sieve Shaker

Test product: Diamond

Mesh size: 30 mesh, 35 mesh, 40 mesh, 45 mesh, 50 mesh

Recommended product: BZJ-300 RO-TAP Sieve Shaker

Test product: seasoning

Mesh size: 30, 40, 60 mesh

Recommended product: BZJ-200 Rotap Sieve Shaker

The price of rotap sieve shaker machine can vary depending on factors like size, brand, and features. However, a general estimate suggests they can range from around $300 to $1,000 USD. For specific and up-to-date pricing information, it is recommended to contact suppliers or manufacturers directly for accurate quotes.

1. Prepare the screen frame and the material to be tested

2. Put the sieve frame into the rotap sieve shaker and install the sieve frame

3. The tray supports the screen frame to a proper position, and tightens the screws

4. Close the flap and put down the hammer

5. Turn on the power, adjust the timer time, and start working

Note: The rotap sieve shaker has a timing device, the user can adjust the use time, and it will automatically stop when it is turned on. The first two digits of the adjustment time are minutes, and the last two digits are seconds. Users can adjust the running time according to their needs.

Dahan manufacturers mainly operate: rotap sieve shaker, two-seat rotap sieve test sieve shaker and other laboratory particle size testing tools, complete model parameters, can provide a variety of supporting facilities, factory direct sales, low price, has successfully served more than 80 countries and regions around the world. area.

The manufacturer promises: Standard parts are in stock, 7 working days for special customization, free shipping from the manufacturer, and quality problems within 30 days, users can choose free maintenance or replacement, one-year warranty, and lifetime warranty.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.