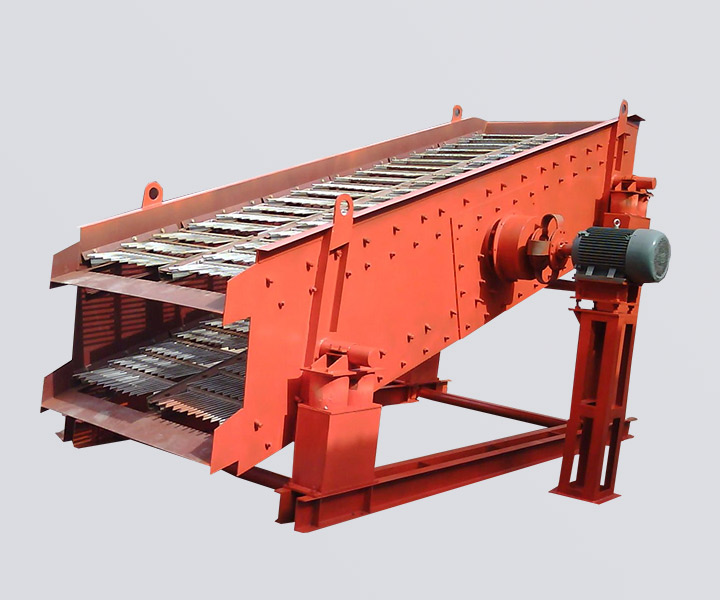

Circular motion tilting screens are used to sort materials at different stages of the crushing process and final product separation

![]()

![]()

![]()

Price:$800.00-$5,000.00 /Set

Consult now and enjoy a 10% discount

Mesh size: 4-200mm

Processing capacity: 12-600t/h

Layers: 1-5 layers

Tilt angle: 15-30 degrees

Power: 7.5-37KW

Application scope: screening of sand and gravel, screening of coal mines and other ore screening with particle size> 3mm.

Commitment:

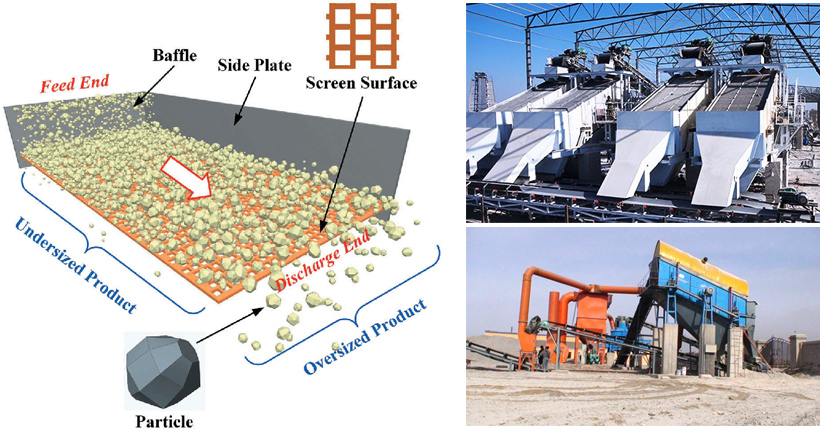

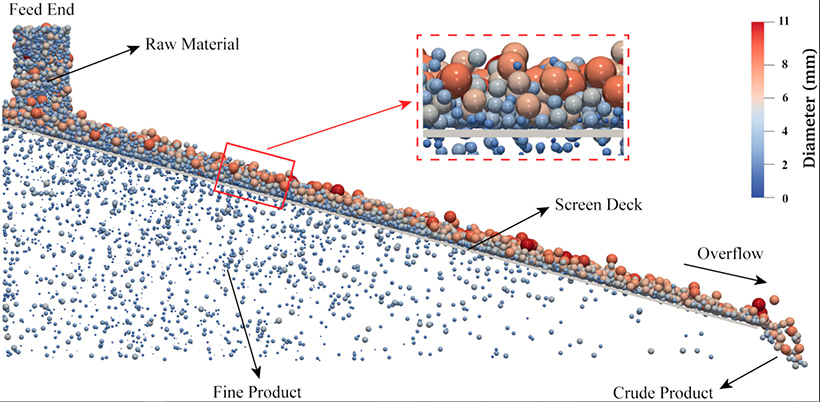

Vibrating screens, also known as inclined vibrating screens or inclined screens, are used to sort materials at different stages of the crushing process and separation of the final product.Circular motion inclined screens typically lend themselves to scalping operations. The circular motion causes the material to roll down the deck. This helps reduce "plugging" of the near size material in the openings. Elliptical motion inclined screens operate in much the same way as the circular motion version. Depending on drive placement, this screen can speed up the travel rate on the feed end and slow it down on the discharge end.

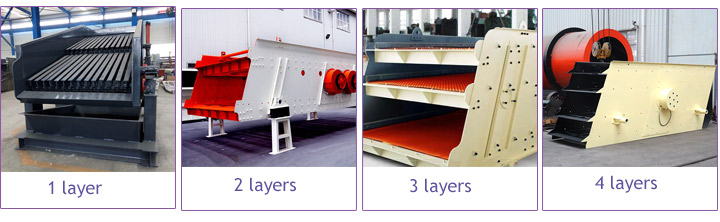

Our inclined screens provide single, double and triple layer configurations in various sizes ranging from 2 sqm to 16 sqm, available in different types of media such as grille, perforated sheet, polyurethane and steel, and provide A wide range of cleaning options to meet requirements provides maximum durability with customizable features and accessories.

The motor makes the eccentric block of the exciter rotate at high speed through the V-belt. The running eccentric block generates a large centrifugal force, which stimulates the screen box to produce a circular motion with a certain amplitude. The material on the screen is subjected to the impulse transmitted by the screen box on the inclined screen surface to produce a continuous throwing motion. The process of meeting the material and the screen surface The particles smaller than the sieve opening are made to pass through the sieve, so as to realize the classification.

Circular motion inclined screens

Circular motion inclined screens typically lend themselves to scalping operations. The circular motion causes the material to roll down the deck. This helps reduce "plugging" of the near size material in the openings.

High production

Using small amplitude, high frequency, the inclination of the screen varies from 15 to 30 degrees, the feeding particle size is 400mm, and the processing capacity per hour ranges from 80-620 tons.

Multi-layer grading

The machine can provide single-layer, double-layer, three-layer and four-layer sieve plates, and can carry out product classification of 1-5 different specifications, and the specifications of each grade are clearly screened.

Durable

Inclined vibrating screens are constructed with high-strength heat-treated side panels that are resistant to vibration, allowing our customers to use them for long periods of time.

Reduce maintenance costs

With a no-weld design, the side panels are bolted to the main frame with vests. This robust construction ensures a long service life and reduces maintenance costs.

Customizable

High-manganese steel woven screen, punching screen and rubber screen can be used according to materials and user requirements, and can be selected according to the processing materials.

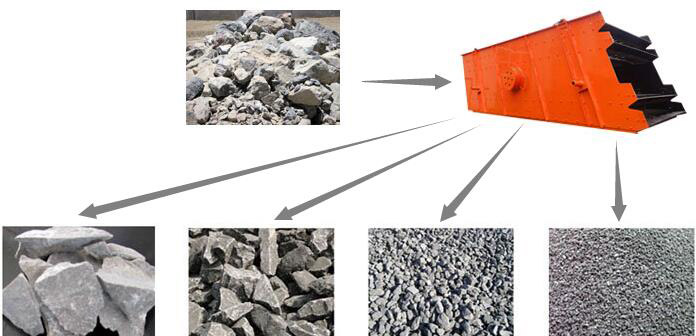

Sieving sand and gravel

Sieving stone

| Model | Screen surface parameters | Feeding granularity (mm) |

Handling capacity (t/h) |

Double amplitude (mm) |

Motor | Single point dynamic load (N) |

Dynamic load (N) |

||||

| Layer | Area(m²) | Inclination(degree) | Apeture(mm) | Model | Power(kw) | ||||||

| YK1230 | 1 | 3.6 | 15-30 | 3-50 | ≤200 | 220 | 6-10 | Y160M-6 | 7.5 | 440 | 2200 |

| 2YK1230 | 2 | 3.6 | 15-30 | 3-50 | ≤200 | 220 | 6-10 | Y160L-6 | 11 | 732 | 3660 |

| YK1530 | 1 | 4.5 | 15-30 | 3-50 | ≤200 | 250 | 6-10 | Y160L-6 | 11 | 720 | 3600 |

| 2YK1530 | 2 | 4.5 | 15-30 | 3-50 | ≤200 | 250 | 6-10 | Y200L1-6 | 18 | 1154 | 5770 |

| YK1545 | 1 | 6.75 | 15-30 | 3-50 | ≤200 | 300 | 6-10 | Y180L-6 | 18 | 845 | 4225 |

| 2YK1545 | 2 | 6.75 | 15-30 | 3-50 | ≤200 | 300 | 6-10 | Y200L1-6 | 22 | 1360 | 6800 |

| YK1845 | 1 | 8.1 | 15-30 | 3-50 | ≤200 | 350 | 6-10 | Y180L-6 | 18 | 936 | 4680 |

| 2YK1845 | 2 | 8.1 | 15-30 | 3-50 | ≤200 | 350 | 10-15 | Y200L-6 | 22 | 1570 | 7850 |

| YK2045 | 1 | 9 | 15-30 | 6-100 | ≤200 | 450 | 10-15 | Y200L-6 | 18 | 987 | 4935 |

| 2YK2045 | 2 | 9 | 15-30 | 6-100 | ≤400 | 450 | 10-15 | Y250L-6 | 22 | 1593 | 7965 |

| YK2060 | 1 | 12 | 15-30 | 6-100 | ≤400 | 550 | 10-15 | Y200L-6 | 18 | 1339 | 6695 |

| 2YK2060 | 2 | 12 | 15-30 | 6-100 | ≤400 | 550 | 10-15 | Y250L-6 | 30 | 2149 | 7590 |

| YK2460 | 1 | 14.4 | 15-30 | 6-100 | ≤400 | 600 | 10-15 | Y250L-6 | 22 | 1518 | 9545 |

| 2YK2460 | 2 | 14.4 | 15-30 | 6-100 | ≤400 | 600 | 10-15 | Y250L-6 | 37 | 2107 | 10535 |

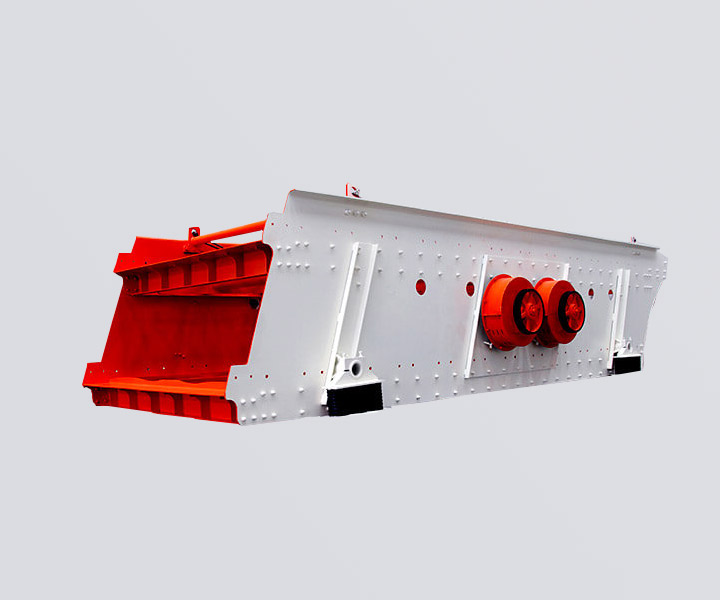

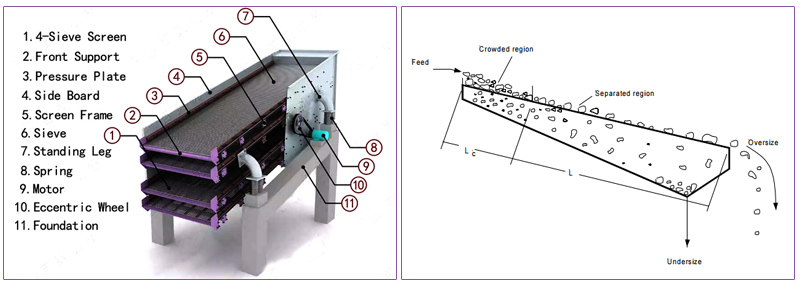

Vibrating screen consists of eccentric vibration exciter, screen box, motor, base and supporting device.

Vibrator: The eccentric structure is adopted, and the feeding box can be selected. The application of the feeding box increases the effective screening area of the vibrating screen and prolongs the service life of the screen at the feeding end.

Transmission part: an intermediate transition bearing seat is added. The application of the intermediate transition bearing seat effectively protects the motor and prolongs the service life of the motor.

Motor: Installed on the left side of the screen frame, and can also be installed on the right side of the screen frame.

This series of screen machines are seat-mounted. The adjustment of the inclination angle of the screen surface can be realized by changing the height of the spring support.

It is suitable for screening sand and gravel materials in quarries, and can also be used for product classification in coal preparation, mineral processing, building materials, electric power and chemical industries.

The following factors need to be considered in the selection of vibrating screens: screening mesh number, production capacity, screening particle size range and material characteristics. First, determine the required screening mesh and particle size range according to the production process and product requirements, and then determine the size and specification of the vibrating screen based on the production capacity. According to the material characteristics, select the appropriate screen material and structure to avoid clogging and adhesion. In addition, the brand, quality, after-sales service, price and other factors of the vibrating screen also need to be evaluated to choose a vibrating screen product with higher cost performance.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.