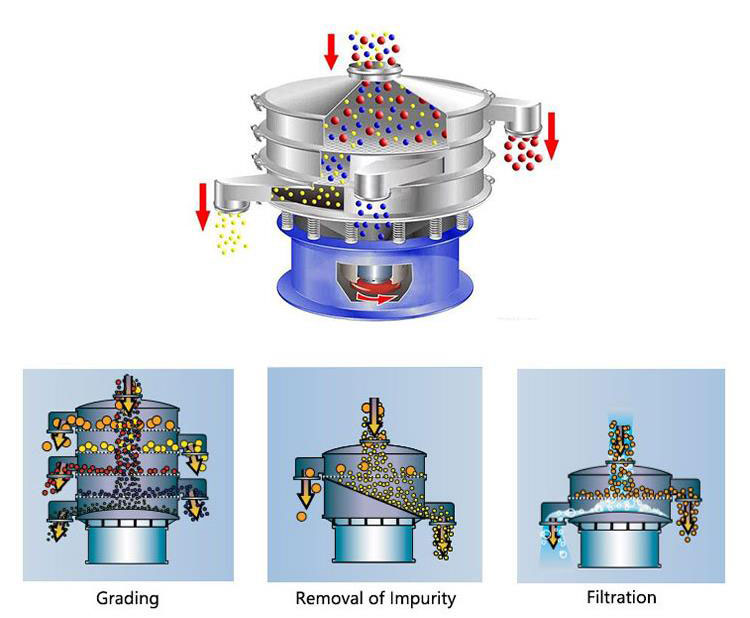

1. Meet the screening requirements. The main purpose of designing a vibrating screen is to be able to meet the required materials and separate qualified products and unqualified products within a certain period of time. Therefore, screening requirements need to be considered when designing vibrating screens, including safety, efficiency, stability, and reliability. At the same time, it is also necessary to consider the characteristics of the material, such as particle shape, size, density, adhesion, etc.

2. The vibrating screen adopts elliptical or linear motion trajectory. The processing capacity is ≥60 L/s, which meets the normal use of 200-mesh sieve cloth.

3. The vibrating screen motor is a short-rod or long-rod explosion-proof excitation motor. The same series of vibrating screens should use the same motor manufacturer, the same specification and type of vibration motor, and they are universally interchangeable. It is advisable to use the vibration motor with adjustable excitation force.

4. Reasonable structure and easy operation. In order to facilitate operation and maintenance, the design of the vibrating screen should consider the rationality of the structure. Therefore, the vibrating screen should have simple operation control and maintenance. At the same time, the labor intensity should be fully considered in system design to ensure the safety and health of operators.

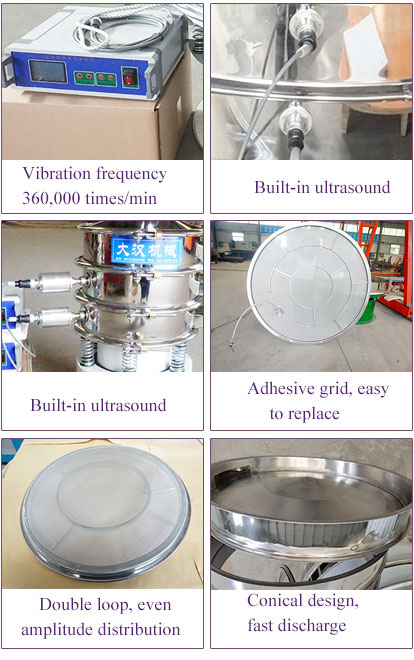

5. Appropriate vibration force and vibration frequency. In the design of the vibrating screen, the use requirements need to be considered. For different materials, it is necessary to choose the appropriate vibration force and vibration frequency. When selecting the vibration force, it is necessary to consider the characteristics of the material and the selection of the screen; when selecting the vibration frequency, it is necessary to fully consider factors such as output, screen aperture and material properties.

6. The screening system should use a general-purpose quick-loading plate and frame screen. It is required that the screen itself has high strength, strong interchangeability, and easy installation and disassembly. network (or configure as needed). Hook edge screen can also be used, screen size: 1130×780 mm.

7. The screen and sieve bed must use a fully sealed structure with buckle installation. The temperature resistance of the sealing rubber strip is ≥120°C, oil-based mud resistance, corrosion resistance, and good sealing; the rubber parts are oil-resistant rubber parts (Nitronitrile rubber) And provide a third-party certificate.

8. The tilt angle adjustment device of the vibrating screen adopts a mechanical or hydraulic adjustment device to realize stepless adjustment. The tilt angle of the screen box can be dynamically adjusted according to the needs to meet the needs of different drilling conditions.

9. Screen tensioning method, priority is to use wedges for quick compression, and a spiral fast tensioning device can be used. The screen replacement does not exceed 2 minutes per piece, and it should be disassembled directly outside the screen box.

10. Select high-quality components to ensure after-sales service. The selection of vibrating screen components should consider quality assurance and after-sales service. High-quality components such as high-quality wear-resistant and corrosion-resistant must be selected to ensure the service life of the equipment, and the equipment must be regularly maintained and updated to ensure the stable and continuous operation of the vibrating screen.

11. Pay attention to environmental protection and energy saving. The design of the vibrating screen needs to consider the issues of environmental protection and energy saving. The vibrating screen will generate certain noise and vibration during operation. It is necessary to eliminate and control the noise and vibration, and also consider energy-saving measures, such as the use of energy-saving motors and other technical means.

12. The vibrating screen box is suspended on the adjustment system through rubber shear springs. During transportation, the vibrating screen has a transportation fixture specially placed for spring deformation. During use, this device must be completely disassembled before use.

In general, the design of the vibrating screen should fully consider the characteristics of the required materials, use requirements, safety and health, environmental protection and energy saving, etc., and formulate a suitable, stable, reliable and efficient plan in order to effectively Improve the sorting efficiency and production benefits of the vibrating screen.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.