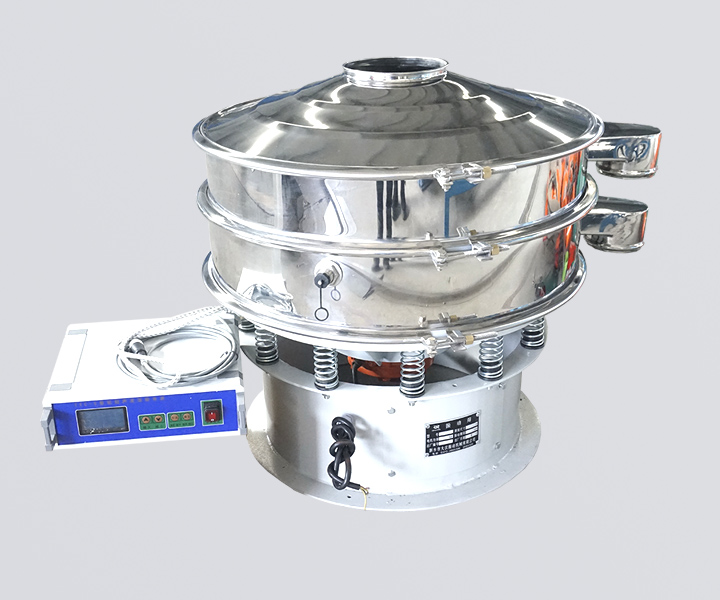

rotary sieving machine

rotary sieving machine industrial sieving machine

industrial sieving machine powder sieving machine

powder sieving machine ultrasonic sieving machine

ultrasonic sieving machine stainless steel sieving machine

stainless steel sieving machine

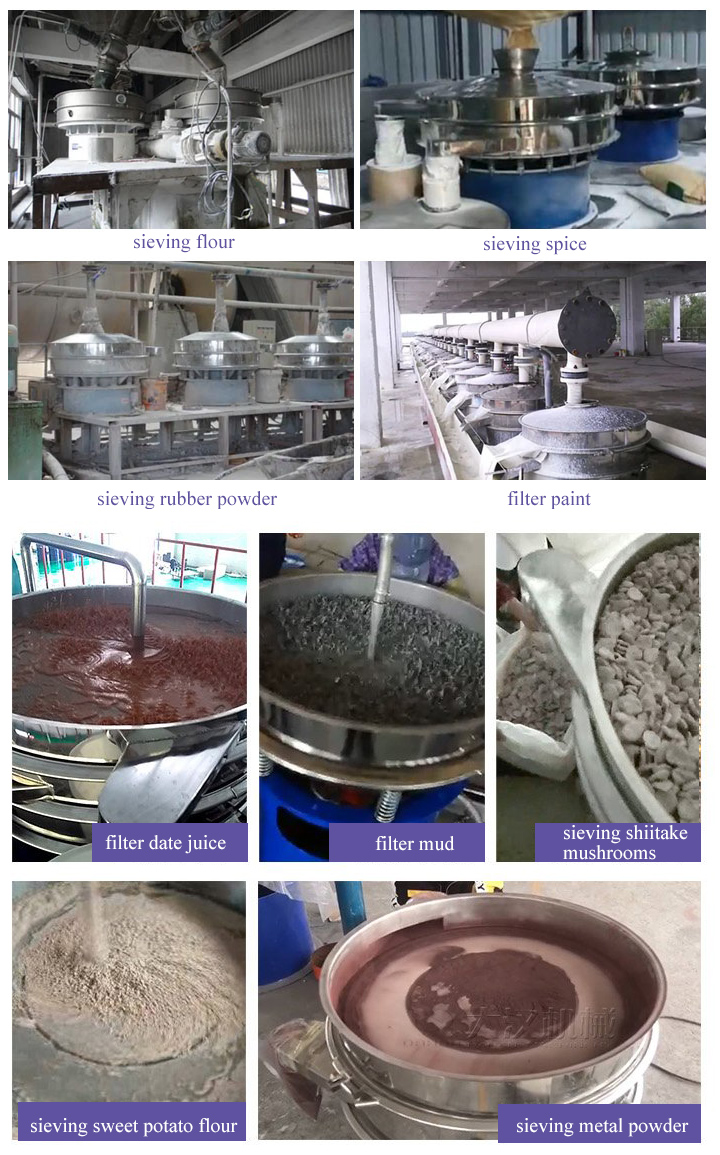

Safe screening for foreign matter elimination, separation of different particle sizes in the same product, solid-liquid separation

![]()

![]()

![]()

Price:$800.00-$5,600.00/Set

Consult now and enjoy a 10% discount

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh (or 0.028mm)

Processing capacity: 100-5000kg/h

Layer(s): 1-5 Layers

Power: 0.25KW-2.2KW

Power supply: 3-phase lndustrial electricity

Material: SS304 stainless steel/Q235 carbon steel

Application: food and beverage, medicine, powder coating, metal powder, chemical industry, agriculture, plastics and other industries.

Commitment:

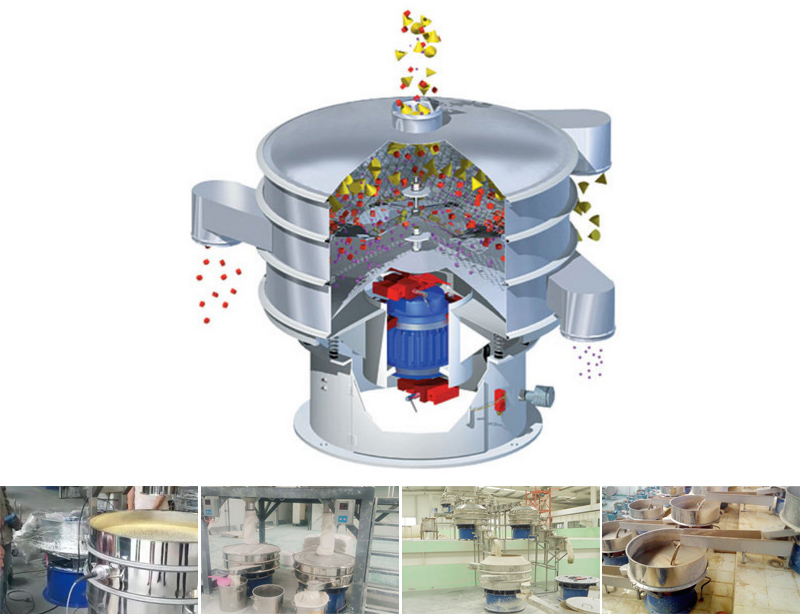

Sieving machines provide a cost-effective solution for almost any separation requirement, including sizing, peeling, grading or product recovery, accurately removing oversized contaminants and agglomerates, or separating the mass components of solids based on particle size Separated from solid and fractionated materials.

To best fit your production line and ensure we can handle any throughput you need, Dahan sieving machines are available in 8 sizes: 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm. It allows a throughput of 100 to 5,000 kg/h, depending on the product, mesh size and the feed flow of the machine.

1. Screening impurities

Used to remove broken or undersized products such as lumps and other contaminants for final quality checks.

2. Particle size classification

It is to accurately separate particles of different sizes from the product, so that the final material is classified into different sizes. This is usually achieved by passing the product through a grid of up to 5 different aperture sizes.

3. Solid-liquid separation

It can quickly remove insoluble solid substances in various slurries, and can quickly discharge slag. Most are single-layered, but multiple layers can also be used.

4. Batch filtering

Improve product quality and safety by breaking down lumps and filtering out oversized particles, contaminants and debris, ideal for smaller processes, batch production or short production runs.

5. Dehydration

For materials with high mud content and high water content, vibrating screen equipment can be used to achieve desliming and dehydration treatment of materials, which can reach 16-18 tons in 1 hour, but this treatment can only be achieved by special vibrating screen equipment.

Contact us for more information on our grading sieving machines range and how we can help you with your unique requirements.

Vibro Sifter

Excessive pollutants can be removed accurately, and the separation of 5 different sizes of materials can be achieved in one operation, and the insolubles in various slurries can be quickly removed. This type of screening machine is used to ensure higher quality of the final product.

Ultrasonic Sieving Machine

Ultrasonic frequencies are used to vibrate the screen so that the mesh does not clog and the powder is easier to screen. The system increases screening capacity by a factor of 10, increasing productivity while allowing separation accuracy down to 20m (#635 mesh).

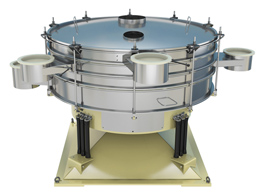

Tumbler Screen

Imitating the principle of manual screening, combining screening (circular motion) with hand screen (parabolic motion), it can be suitable for dry and wet materials, the screening accuracy is 90-95%, and the output is 5-10 times that of vibrating screen. There is no high-speed vibration and will not destroy the shape of the material.

Wide screening range

Any particle, powder, slurry (mucus) can be screened. The sieving can be as fine as 500 mesh (0.028mm), and the filter can be as small as 5 microns.

Precise sieving

Fully enclosed structure, powder does not fly, liquid does not leak, mesh is not blocked, automatic discharge, there is no storage in the machine, and the grid structure has no dead ends.

Multi-layer screening

It can be used in single and multiple layers at the same time, up to 5 layers, and can carry out 2-6 levels of sorting or filtering at the same time.

Simple screen replacement

The composite screen design has longer screen life and higher efficiency. Two people can change the screen within 3 to 5 minutes, which saves 30 to 60 minutes compared to other types of screens.

Increase flexibility

The compact system is easy to move and can be used in multiple locations on the production line.

Low noise level

Internally sealed with air tightness up to 50 mPa and noise level reduced to 69 dBA.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Various powder industries, any particles, powders, and mucus can be screened and filtered within a certain range.

| Special design | Photo | Features |

| Standard |  |

The solid and liquid can be filtered or the dry material can be sized and removed. |

| Ultrasonic type |  |

Adding an ultrasonic screening system and a fine powder screening tool to solve the problem of blocking the mesh. |

| In-line type |  |

Special design, huge processing capacity, easy to combine with production line, good at sieving flour, starch, washing powder, additives, etc. |

| Anticorrosive |  |

The part in contact with the material is made of polypropylene (PP plastic), which is a screening solution for corrosive materials such as carbon steel and stainless steel. |

| Edged type |  |

The specially designed flanged type is a type that has a large feeding volume, prevents material splashing, and is easy to observe the screen. |

| Gate type |  |

There is a gate-type design for the treatment of special materials to ensure the processing accuracy of difficult-to-screen materials and increase the processing capacity. |

| Material | Mesh | Capacity | Model |

| Flour | 24 | 1500kg/h | DH-1000-1S |

| Chinese medicine powder | 80 | 550kg/h | DH-800-1S |

| Salt | 30,80 | 5000kg/h | DH-1500-2S |

| Pollen | 12 | 100kg/h | DH-400-1S |

| Soy sauce | 100 | 6500kg/h | DH-1200-2S |

| Iron powder | 400 | 203kg/h | DH-800-3S |

| Graphite | 16,40,80 | 1400kg/h | DH-1000-3S |

| Mud | 250 | 3200kg/h | DH-1000-1S |

| Refractory | 2.2mm | 10000kg/h | DH-1500-2S |

| Quicklime | 100 | 480kg/h | DH-1000-3S |

Dahan Machinery sieving machine is mainly used for impurity removal and classification of various powders, and is widely used in food, medicine, chemical industry, metallurgy, abrasives, coal and other industries. The manufacturer has won ISO quality system certification and EU CE certification. The product models are complete and can be designed according to the special requirements of individual users. The products are shipped directly by the manufacturer, reducing the profit extraction of middlemen and reducing the purchase cost of users.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.