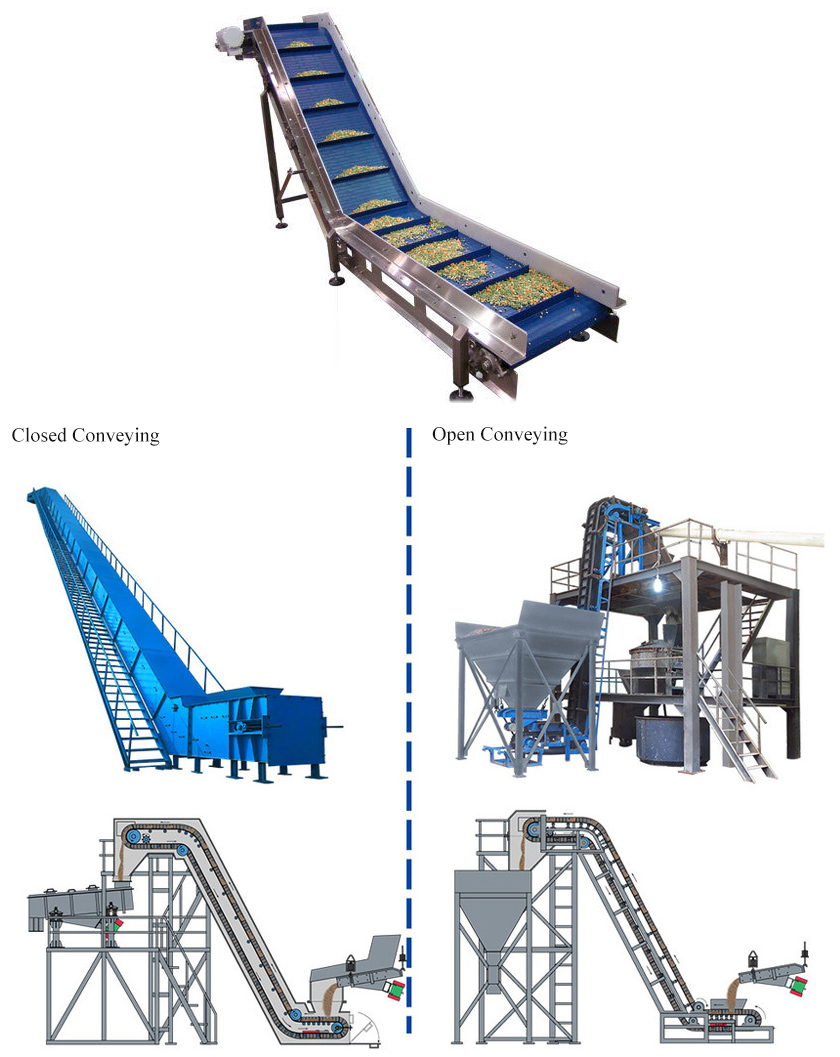

Z type belt conveyor

Z type belt conveyor Food grade z type belt conveyor

Food grade z type belt conveyor Inclined belt conveyor

Inclined belt conveyor Z type belt conveyor with feed hopper

Z type belt conveyor with feed hopper Z type belt conveyor system

Z type belt conveyor system

It can be used for loading and climbing conveying of various materials.

![]()

![]()

Price:$680.00 - $22,800.00/Set

Consult now and enjoy a 10% discount

Machine Type: Z Type

Conveying angle: 0-90°

Belt width: 300-1500mm

Belt Type: Skirt

Speed: 0.8-4.0m/s

Conveying capacity: 28-800m³/h

Conveying length: 6 meters

Belt material: food grade PVC, PU, rubber

Frame material: SUS304 stainless steel/carbon steel/aluminum

Weight: 300 kg

Application: suitable for the continuous transportation of goods with height difference between upper and lower floors, slope terrain, overpass and so on.

Commitment:

Z type belt conveyor is used for feeding and climbing conveying of various materials or transition from another conveyor and elevate up to another piece of equipment or discharge for inspection or assembly. The angle of incline and the discharge horizontal sections are adjustable from 20- 90 degrees for elevation changes.

Z type belt conveyor can complete inclined or vertical conveying in a narrow space. The conveyor belt has rubber side corrugations and partitions, which can avoid the problem of scattered items when conveying at a large angle.

The conveying angle of the Z type belt conveyor can be greater than 30 degrees, and the vertical conveying can even reach 90 degrees. It has the functions of conveying and lifting, and can effectively convey products from low-end to high-end. It is widely used in the food packaging industry.It can also be used in the food industry, warehousing and logistics industry, packaging industry, express delivery industry, electronic and electrical industry, medicine and other industries to help improve the efficiency of transportation and loading and unloading of various goods.

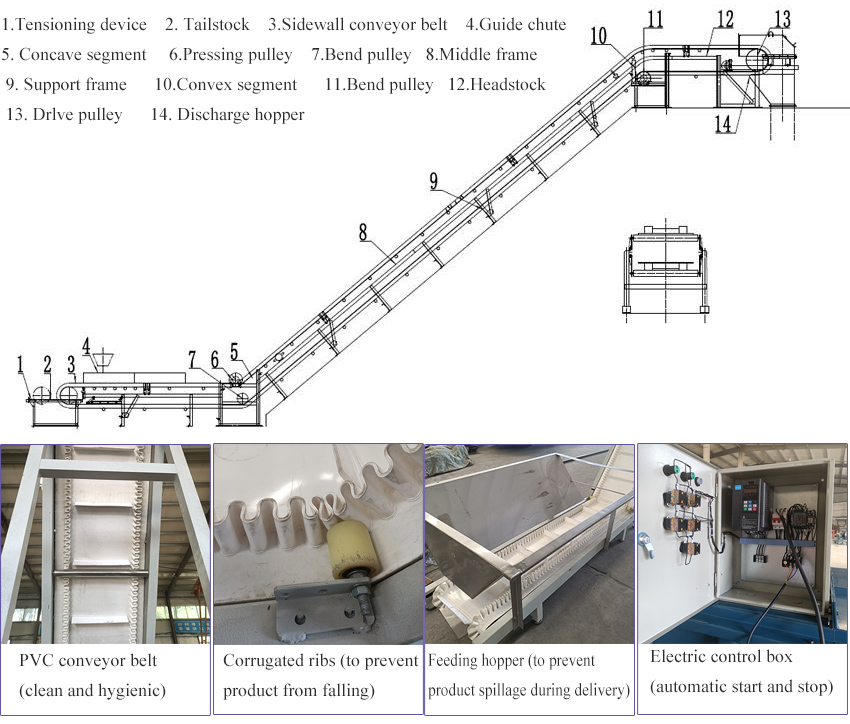

The conveyor belt, as the main traction and bearing member, forms a ring through the drive roller and the tail reversing roller, and the tensioning device provides the conveyor belt with tension during operation to avoid slippage when conveying materials. It provides the support of the material on the conveyor belt, so as to avoid excessive deflection and sag of the conveyor belt and increase the pressure of the driving device, resulting in the failure of the driving roller. The material moves on the conveyor belt through friction with the conveyor belt and is discharged to the destination at the redirecting roller.

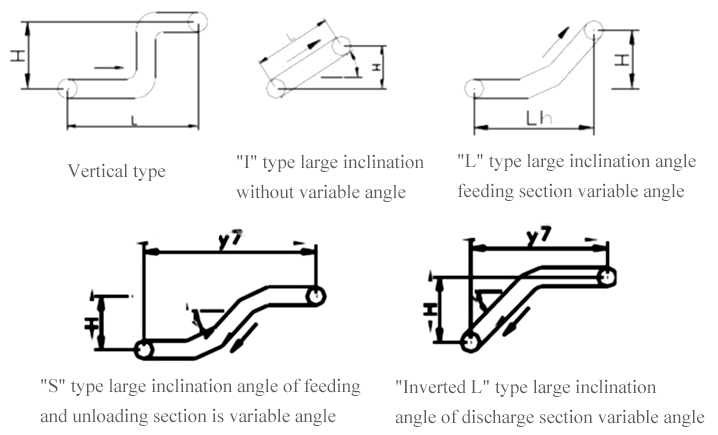

Large inclination conveying

Conveyor belts with corrugated ribs and diaphragms are used. Therefore, it is especially suitable for large inclination angle and vertical 90° conveying, which completely solves the conveying angle that cannot be achieved by ordinary and patterned belt conveyors.

Small footprint

The maximum conveying angle can reach 90°, which is an ideal equipment for large inclination conveying and vertical lifting. It can save floor space, equipment investment and civil construction cost, and the overall investment cost is low, about 20% to 30% of the investment cost.

High conveying efficiency

It can continuously transport materials below 500 kg. For example, if a user wants to lift coal to the top of a 20m-high silo, if a Z-type belt conveyor is used to transport at an inclination of 45°, the length of the machine only needs to be 28.3m (the length of the horizontal machine is 20m). ); and if the z-type belt conveyor for vertical conveying is used, then the horizontal captain can be controlled within 6m.

Low energy consumption

Because there is no excavation resistance during loading and internal friction and external friction resistance of materials during operation, the energy consumption is small. For example, the two vertical Z-type belt conveyors used in Lunan Fertilizer Plant, each with a lifting height of 19.28m and a conveying capacity of 25t/h, each have a power of only 4kW for conveying crushed coal. The power of the four original buried scraper conveyors is 44kW.

Z type belt conveyor for conveying raisins

Z type belt conveyor for conveying peanuts

| Belt Width B (mm) | 400 | 500 | 650 | 800 | 1000 | 1200 | 1400 | |||||||||

| High guard H (mm) | 60 | 80 | 80 | 120 | 120 | 160 | 160 | 200 | 160 | 240 | 200 | 300 | 240 | 400 | ||

| minimum horizontal baffle spacing | 100 | 120 | 120 | 160 | 160 | 200 | 200 | 250 | 200 | 280 | 250 | 350 | 280 | 400 | ||

| Throughput | 30° | 28 | 36 | 50 | 71 | 104 | 120 | 157 | 195 | 216 | 327 | 331 | 466 | 500 | 794 | |

| (raw coal,idling 1m/s) | 45° | 19 | 25 | 33 | 57 | 83 | 97 | 127 | 157 | 175 | 271 | 267 | 384 | 414 | 680 | |

| M³/h | 60° | 15 | 19 | 23 | 40 | 58 | 69 | 90 | 112 | 124 | 197 | 190 | 278 | 302 | 524 | |

| 90° | 9 | 11 | 15 | 21 | 31 | 37 | 48 | 60 | 66 | 106 | 102 | 149 | 162 | 281 | ||

| Overall dimensions | High head belting leather surface H1 | |||||||||||||||

| 1200 | 1350 | 1615 | 1815 | 2000、2200 | 2300、2525 | 2525、2700 | ||||||||||

| High end belting leather surface H2 | ||||||||||||||||

| 690 | 800 | 950 | 1115 | 1250、1400 | 1600、1700 | 1600、1700 | ||||||||||

| High middle section of belt surface H3 | ||||||||||||||||

| 700 | 800 | 850 | 1115 | 850、1200 | 1400、1500 | 1600、1700 | ||||||||||

| middle period of anchor wide B1 | ||||||||||||||||

| 580 | 850 | 1020 | 1220 | 1440 | 1690 | 1890 | ||||||||||

Z type belt conveyor is generally composed of unloading part, transmission part, driving part, brake, backstop, tensioning device, fuselage, deep groove idler device and tail device.

Conveyor length: generally 1m, 2m, 3m, 4m, 6m, 10m, other sizes can be customized.

Belt wire rack material: carbon steel, stainless steel, aluminum profiles.

Conveyor belt: 2mm, 3mm, 5mm, thick PVC belts can be used, and PE, PU belts, and anti-static belts are also available.

Wire brackets are: stainless steel, aluminum profiles, carbon steel spray, etc.

Conveyor feet: adjustable feet, casters;

Conveyor pallet: one-piece and split type can be used, and the split type can be made of carbon steel galvanized sheet, stainless steel sheet, etc.

Bar skirt: optional heights of 20mm, 30mm, 40mm, 50mm, 60mm, etc.

Bar spacing: 100mm-1000mm range, other sizes can also be customized.

The conveying speed is generally: 0.1 ~ 10M/min; the speed can also be adjusted or fixed according to the needs of the user.

Z type belt conveyor adopts "Z" shape construction method, which is mainly composed of upper horizontal section, inclined section and lower horizontal section.

1. Lower horizontal section: low-type intermediate frame legs are used for smooth loading of materials during loading, reducing the pressure on the conveyor during loading and reducing material scattering.

2. Inclined section: The horizontal section adopts low, middle or high intermediate frame legs, and the inclined section adopts low intermediate frame legs. When the inclination angle of the conveyor is higher than 45°, it is recommended to use the type II low-type intermediate frame outriggers.

3. Upper horizontal section: It is the discharge end. According to the discharge requirements of different heights, the height of the head frame used is different, and the legs of the intermediate frame need to be matched according to the head frame.

Xinxiang Dahan specializes in z type belt conveyors, with complete models, low prices, 1-year warranty, and free surveys to provide drawing parameters. We can help you choose and design according to material particle, lifting height, lifting amount, many years of on-site survey and actual production and design experience. The manufacturer has: technical design and drawing department, production department, assembly department, inspection department, purchasing department, sales department , After-sales service. The production sequence is based on verifying working conditions and needs with customers, designing and selecting models, drawing drawings for customers to confirm, making sure that they are correct, arranging to do, viewing drawings and cutting materials, purchasing parts, workshop production, parts inspection, assembly, test machine, painting, packaging ,Ship.

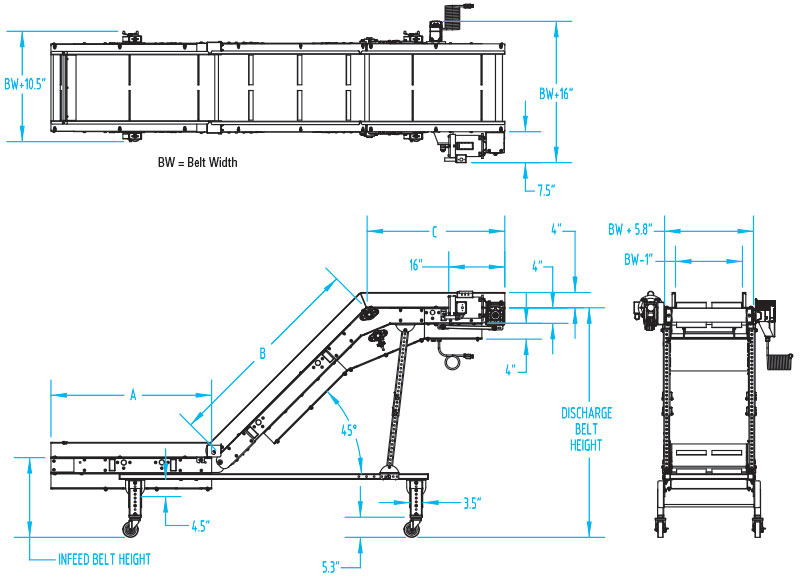

Please provide the following information:

1. The conveyor model you ordered

2. The belt width you need (standard widths are 6", 9", 12", 18", 24", 30")

3. Required feed length in feet (A dimension) Minimum length 2.5'. A + B + C cannot exceed 15'

4. You need slope length in feet (B dimension) Minimum length 2.5'. A + B + C cannot exceed 15'

5. Top shelf length you need in feet (C dimension) Minimum length 3'. A + B + C cannot exceed 15'

Note: Other widths, lengths and conveyor speeds are available.

BW = belt width

Address:China,Yanjin county forest park gate to the west 1000 meters north road.