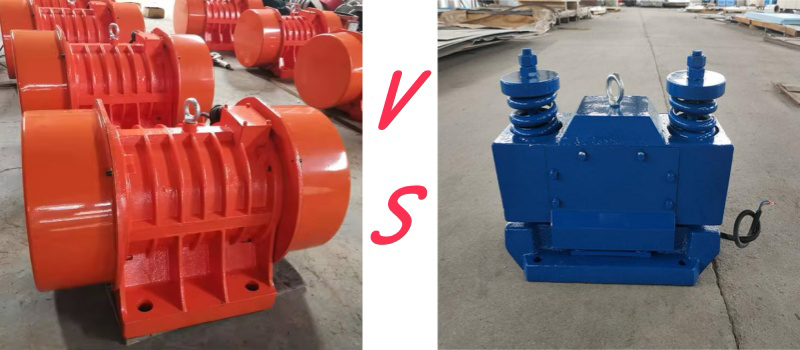

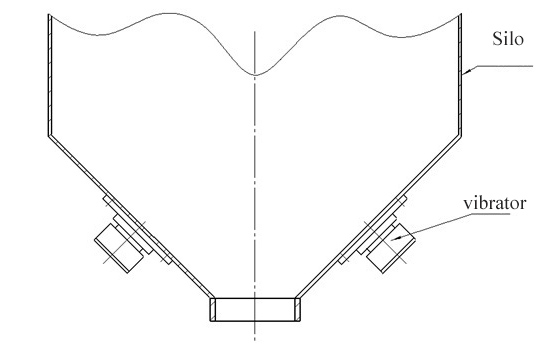

Warehouse wall vibrator is one of the commonly used accessories of mechanical equipment. The silo wall vibrator is used to prevent and eliminate the "blocking" and "tower arch" phenomenon caused by the internal friction, deliquescence, electrification and component segregation of materials in various silos; It can also be used to remove all kinds of warehouse walls and pipeline bonding materials. Warehouse wall vibrator can be divided into electromagnetic warehouse wall vibrators and motor warehouse wall vibrators.

Electromagnetic warehouse wall vibrators and motor warehouse wall vibrators are two types of vibration equipment commonly used in industrial production. They have some significant differences in structural principles and applications. Today, Dahan Machinery will share with you the difference between electromagnetic warehouse wall vibrators and motor warehouse wall vibrators.

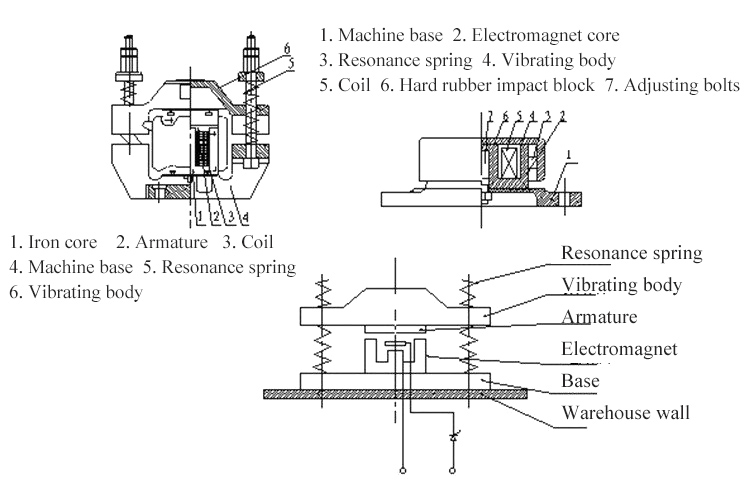

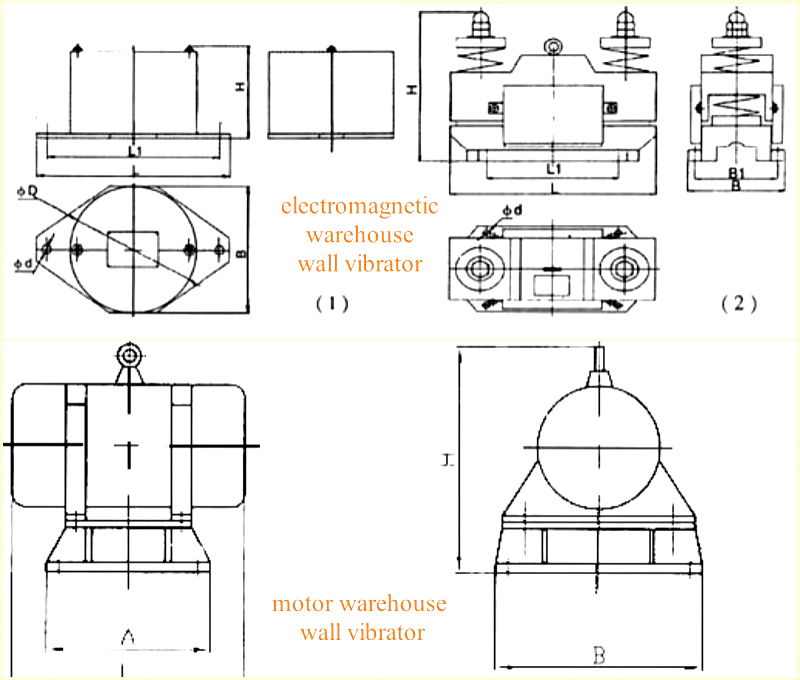

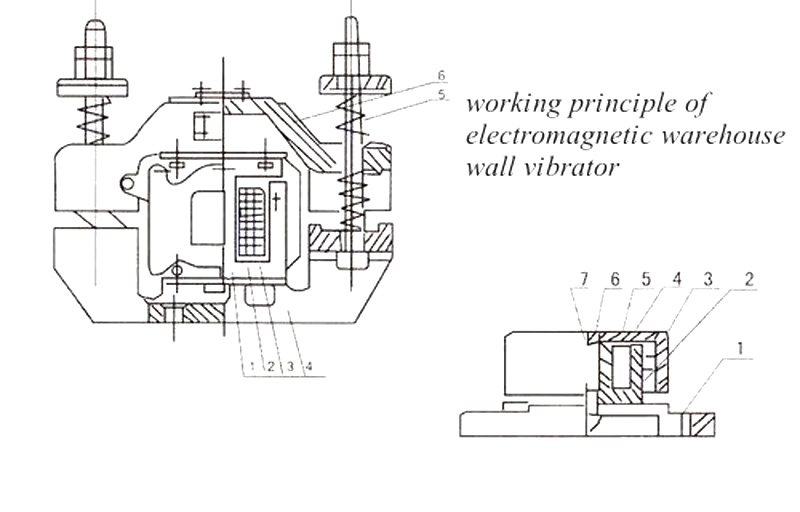

The motor-type warehouse wall vibrator is composed of a vibration motor and a base. The electromagnetic warehouse wall vibrator is composed of a vibrating body, a resonance spring, an electromagnet, and a machine base.

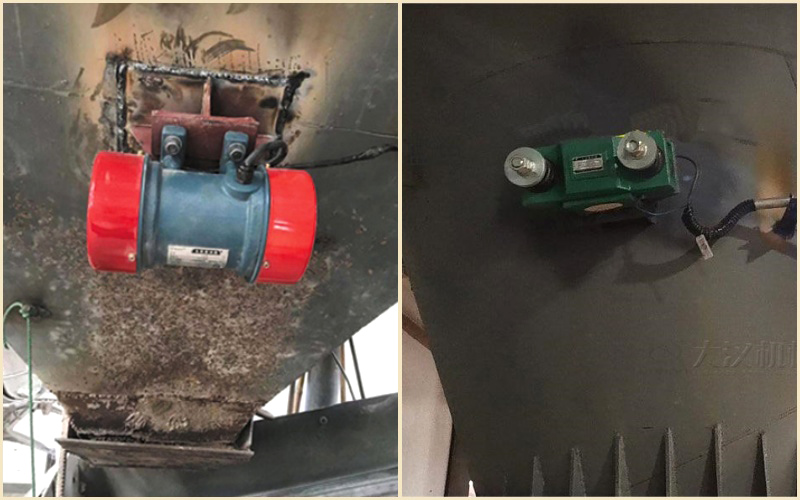

The motor-type warehouse wall vibrator consists of a vibration motor and a base. The vibration motor and the base are tightly fixed as a whole by bolts. Since the base is firmly installed on the wall of the silo, a single-particle directional forced vibration system is formed.

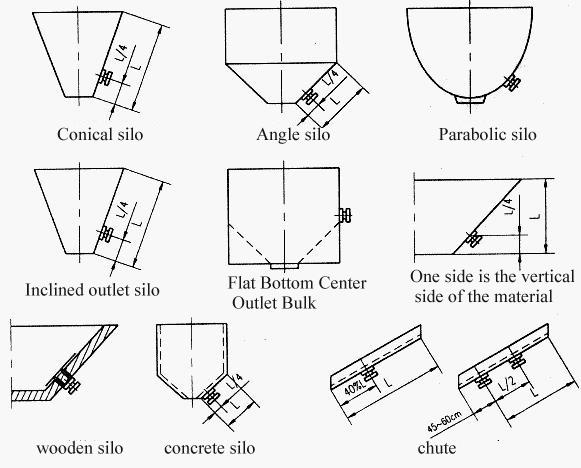

When the silo wall vibrator works, the high-speed rotation of the vibrating motor produces periodic high-frequency vibrations on the silo wall. Due to the periodic vibration of the anti-blocking device, on the one hand, the material is out of contact with the silo wall, eliminating the material and the silo wall. The friction of the silo wall, on the other hand, makes the material in an unstable state under the influence of the alternating speed and acceleration, so as to effectively overcome the internal friction and aggregation force of the material, so as to eliminate the relative stability between the materials in the silo and make the The material is discharged smoothly from the silo mouth.

The control principle of the electromagnetic warehouse wall vibrator is half-wave rectification. The electromagnetic coil is powered by alternating current through diode rectification. When the line is connected, the positive half-cycle pulsating DC voltage is applied to the electromagnetic coil. Due to the action of the electromagnet, a pulsed electromagnetic force is generated between the vibrating body and the base, and the vibrating body is attracted. At this time, the elastic system stores potential energy. The semi-circular diode is not conducting, and the electromagnetic force disappears. With the help of the potential energy stored in the elastic system, the vibrating body vibrates in the opposite direction. In this way, the vibrating body vibrates back and forth at the frequency of the alternating current. The periodic high-frequency vibration of the vibrating body is transmitted to the silo wall through the "impact block". Periodic vibration of the warehouse wall. On the one hand, the material is out of contact with the silo wall, and on the other hand, the material is affected by the alternating speed and acceleration. In an unstable state, it can effectively overcome the internal friction and aggregation force of the material. Make the material discharge smoothly from the silo mouth.

The motor warehouse wall vibrator uses 380V voltage as the working power supply, and can be designed as an explosion-proof type according to the actual situation of the user. The electromagnetic warehouse wall vibrator relies on high-frequency vibration and impact force to ensure stable feeding, and uses 220V voltage as the working power supply.

The motor warehouse wall vibrator can be made into explosion-proof type and can be used in the occasions with explosion-proof requirements, but the electromagnetic warehouse wall vibrator cannot. The excitation force and power of the electromagnetic warehouse wall vibrator are smaller than those of the motor-type warehouse wall vibrator, and the suitable warehouse wall of the electromagnetic type is thinner.

The above is the difference between motors and electromagnetic warehouse wall vibrators summarized by Dahan manufacturers. I hope they can help you distinguish products and choose products more quickly. At the same time, if you need these two types of warehouse wall vibrators, you can click to chat online at any time. We have different models of warehouse wall vibrators and can recommend the type you need.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.