Ultrasonic vibrating screen is a new type of vibrating screening equipment, which is characterized by small size, light weight, free movement, and high screening accuracy (it can screen fine powder materials below 600 mesh, and the screening accuracy can reach 1-100% ), large output (1-10 times that of ordinary round sieves), fully enclosed design without dust pollution, clean and elegant appearance, no secondary pollution to materials, and sanitary and anti-corrosion.

Working principle of ultrasonic vibrating screen

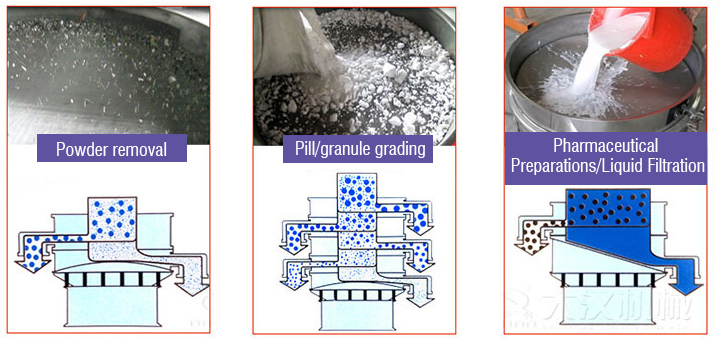

The ultrasonic screening system is composed of ultrasonic resonance power supply, oscillator, outer mesh ring and resonance ring. The high-frequency electrical oscillations generated by the ultrasonic resonant power supply are converted by the oscillator into longitudinal oscillating waves in the form of high-frequency sinusoids. These oscillating waves are transmitted to the resonant ring through the transducer base to resonate the resonant ring, and then the resonant ring transmits the vibration evenly. to the sieve surface. The materials on the screen are subjected to low-frequency three-dimensional vibration, and ultrasonic vibration is superimposed, which can not only prevent the mesh from clogging, but also improve the screening output and quality.

Ultrasonic vibrating screen is a kind of vibration wave greater than 20000 Hz. In ultrasonic vibrating screen, we generally use the frequency band between 30000-40000 Hz. Its vibration characteristics are: the mesh wire generates a sinusoidal longitudinal propagating sound wave with strong penetrating ability and greater than 20,000 times at a small amplitude, and bounces off the material adhering to the screen, so as to prevent the material from clogging the screen. the goal of.

Ultrasonic vibrating screen can effectively screen fine powder materials below 600 mesh, and can pass 1200 mesh slurry materials. It can be widely used in food, chemical industry, medicine, metal metallurgy, plastics, abrasives, silicon carbide, electromagnetic powder, tungsten powder, Cobalt powder, nickel powder, quartz powder, positive electrode material for lithium battery, negative electrode material, laser powder, carbon powder, powder coating, alloy powder, molybdenum powder, stainless steel powder, malt powder, spore powder, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.