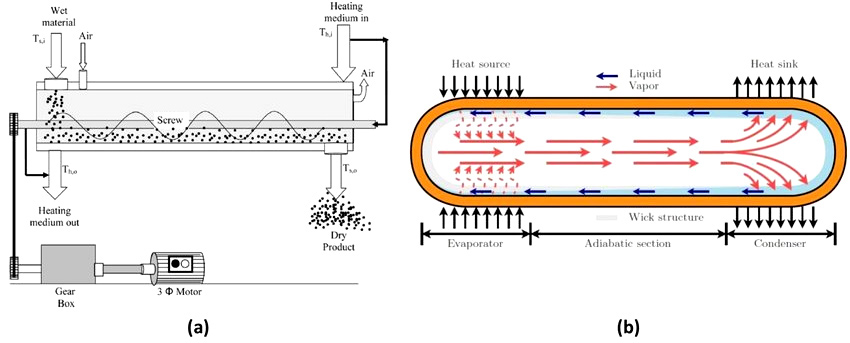

Water cooled screw conveyor is a cooling equipment for the heat conduction in the tank of the water-cooled jacket structure of the rotary kiln waste.

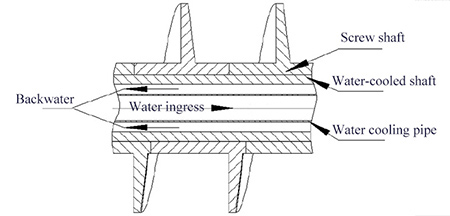

Water cooled screw conveyor consists of screw shaft, water cooling shaft, water cooling pipe and rotary joint.

Spiral shaft: It is made of high temperature and wear-resistant materials, which can be replaced separately. The split spiral blades are easy to disassemble and assemble, and the material flows more smoothly, avoiding local stacking.

Water-cooled shaft: It is a hollow structure.

Water cooling tube: used for circulating cooling of water cooling shaft.

At the inlet end of the screw conveyor, the cooling water has an empty pipe flowing through the screw, and after the plate cavity flows out from the empty discharge pipe, an internal cooling water channel is formed to achieve the specified outlet temperature of the product.

Water cooled screw conveyor The temperature of the conveyed material entering the screw inlet is 450 degrees, and the temperature should drop below 100 degrees when the material is discharged. , commonly used in industries such as high temperature slag, cooling fly ash of coal-fired power plant boilers, and maintaining a specific temperature of food.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.