stainless steel

stainless steel  full stainless steel

full stainless steel  ultrasonic vibro sifter

ultrasonic vibro sifter  mobile vibro sifter

mobile vibro sifter  plastic vibro sifter

plastic vibro sifter

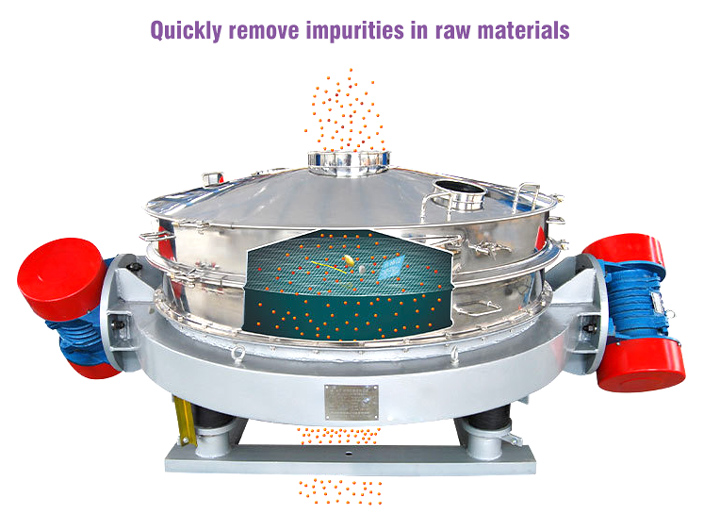

Mainly used for powder removal and loosening

![]()

![]()

![]()

Price:$760.00-$3,090.00/Set

Consult now and enjoy a 10% discount

Screening accuracy: 140 mesh

Capacity: 3-30 tons/hour

Power:2×(0.18-0.75)kW

Motor speed:1460r/min

Customizable: Single motor/Double motor/Explosion-proof type/Ultrasonic type (As you need)

Commitment:

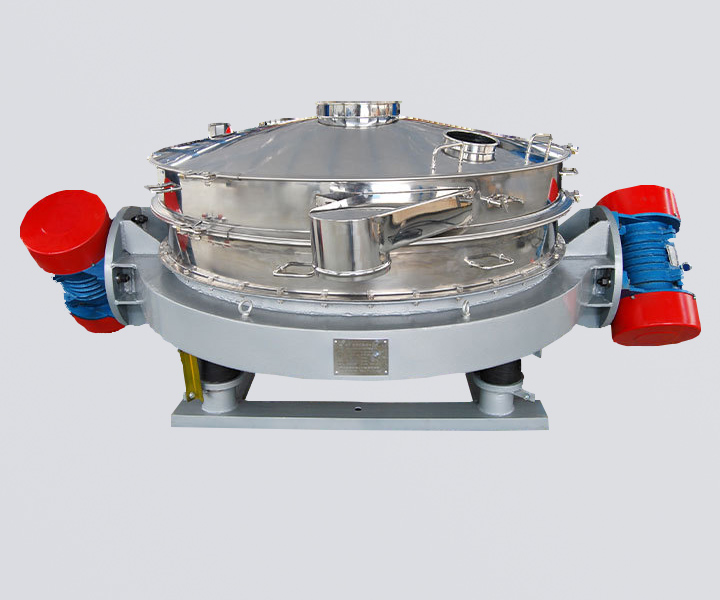

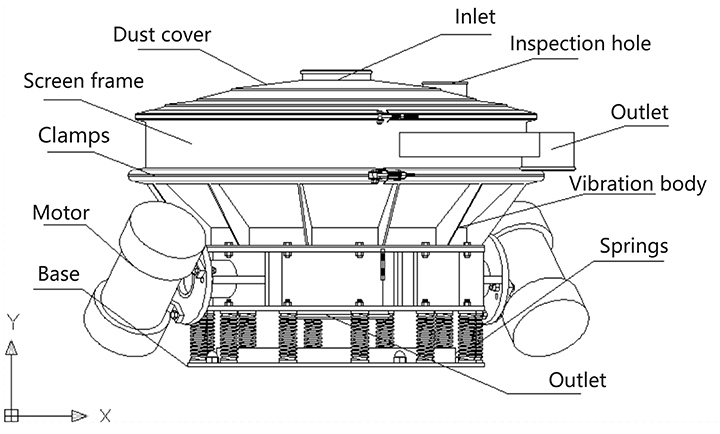

Direct discharge sifter is a circular vibrating sieve used for sieving powder. It is also called flour sieve. The discharge port of the direct discharge vibrating sieve is designed at the bottom of the sieve, which is beneficial to increase the discharge particle size and discharge volume, and has a large capacity. , It is 2-5 times of ordinary circular vibrating screen. It is suitable for the process of rough screening of materials in addition to impurities.

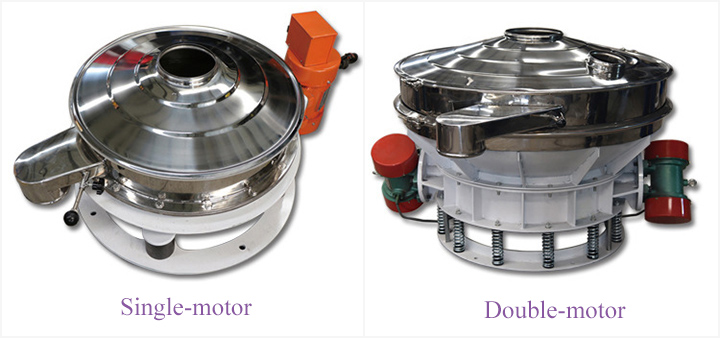

Direct discharge sifter can choose to use dual vibrating motors or single vibrating motors according to the amount of processing. Small screens generally use a single vibrating motor, and screens with larger processing capacity use dual vibrating motors.

Double-motor direct discharge sifter: Double-motor, the material produces vortex motion on the surface of the screen, with automatic discharge function;

Single-motor direct discharge sifter: Single-motor, the material mainly vibrates up and down on the surface of the screen, without automatic discharge function.

Large capacity

The feeding port and the discharging port are on the same center line to help reduce the screening time, the material stays in the screen machine for a short time, and the material is discharged quickly.

Used in series in the system

It can be used directly in the pipeline in series to remove foreign matter and impurities in the pipeline without manual operation and avoid secondary pollution of materials.

Clean operation

The airtightness is good, the powder does not fly, and it can be directly used in conjunction with the vacuum feeder to achieve negative pressure and dust-free operation.

Occupies little space

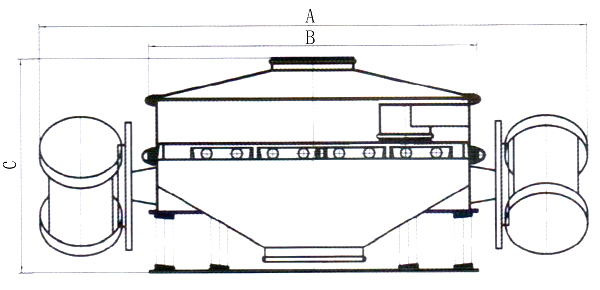

The motor is designed on the outside of the equipment to reduce the height of the equipment and make the space effective; the equipment is easy to operate, and the large obtuse angle is easy to clean.

direct discharge sifter for flour

direct discharge sifter for feed pellets

| Model | Power(kw) | RMP(r/min) | Sieve diameter(mm) | A | B | C |

| ZPS-600 | 0.18 | 1460(960) | 520 | 1070 | 600 | 502 |

| ZPS-800 | 0.25 | 720 | 1390 | 800 | 525 | |

| ZPS-1000 | 0.37 | 890 | 1566 | 970 | 543 | |

| ZPS-1200 | 0.55 | 1090 | 1875 | 1170 | 814 | |

| ZPS-1500 | 0.75 | 1390 | 2226 | 1470 | 875 |

Vibration motor: Dual-motor power generates higher vibrations to achieve high performance.

Inlet and outlet: The inlet and outlet are on the same centerline to help reduce the screening time.

The intermediate sieve body is equipped with the impurities that are screened out, and the mesh size of the sieve is prepared to be equipped with a sieve.

The inline vibro sifter with dual motor is structured with two vertically mounted motors on each side, it helps in increasing vibration & throughput capacity. Due to vibration from both the ends vertical, horizontal & the circular motion is also generated that helps to reduce the sieving process time.

It can screen and filter any powder, granule, liquid; it is widely used in fertilizer, medicine powder, salt, monosodium glutamate, seasoning, milk powder, starch, flour, rice flour, carbon powder, graphite powder, strong powder, etc.

| Date | Product | Customer |

| 2020/12/21 | 1 Set ZPS1200-1S Direct Discharge Sifter | Henan*** Paint Co., Ltd. |

| 2020/10/10 | 1 Set of ZPS600 Direct Discharge Sifter | Heilongjiang*** Nutritional Food Co., Ltd. |

| 2020/8/19 | 1 Set ZPS-600 Direct Discharge Sifter | Ningxia ** Technology Co., Ltd. |

| 2020/8/6 | 1 Set ZPS-600, ZPS-1000 Direct Discharge Sifter | **Industrial Control (Guangdong) Automation Technology Co., Ltd. |

| 2020/6/17 | 1 Set 1200-1S Direct Discharge Sifter | Anyang ** Leasing Co., Ltd. |

| 2020/1/9 | 1 Set ZPS-1000-1S Direct Discharge Sifter | Dezhou ** Biotechnology Co., Ltd. |

The direct discharge sifter has complete models and sufficient stock, which can be customized according to your requirements.

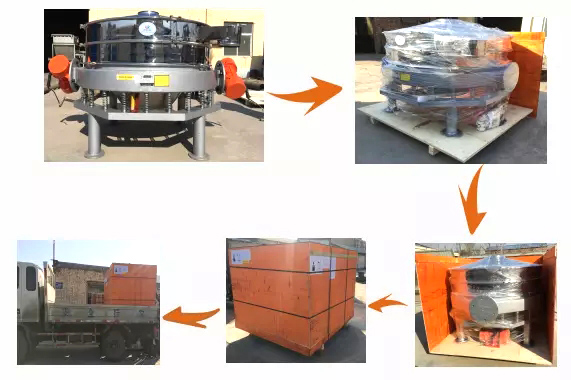

Packaging and transportation of direct discharge sifter

We usually pack them in export cases, and the machines are fixed on the bottom support

Address:China,Yanjin county forest park gate to the west 1000 meters north road.