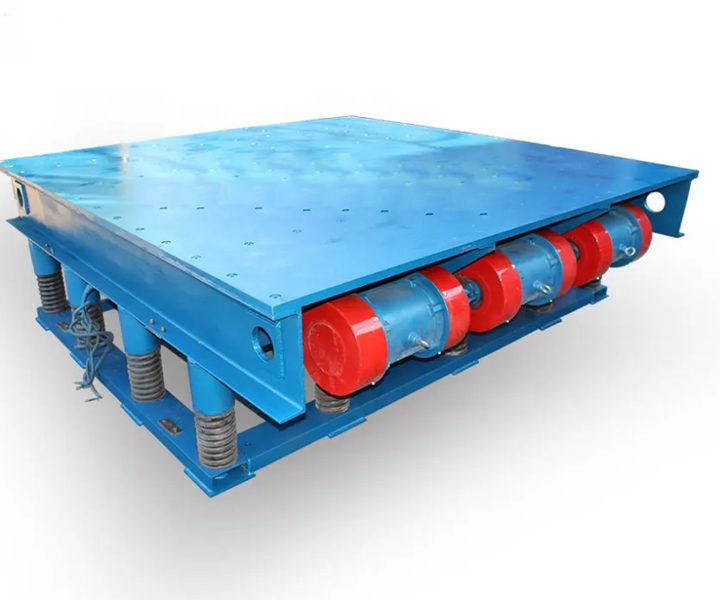

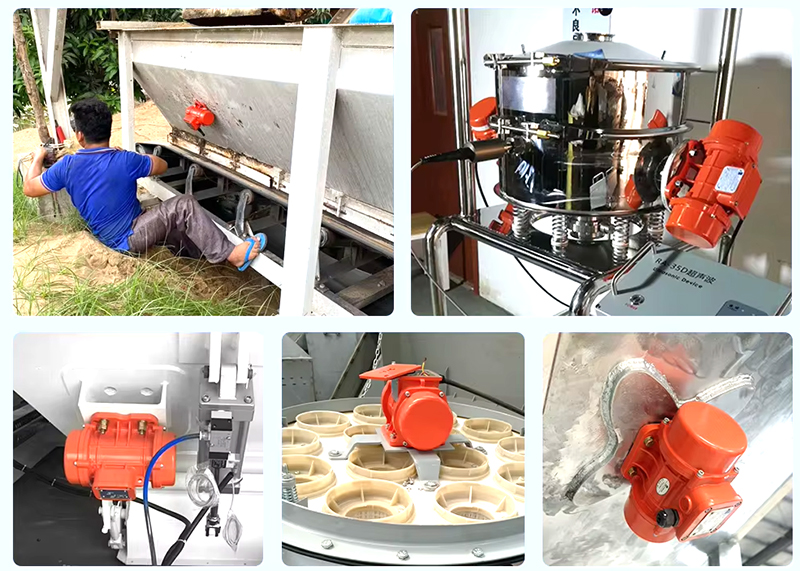

It is used as a vibration source for various vibrating screens, vibrating feeders, vibrating finishing machines, vibrating tables, silo arch breaking, anti-blocking devices and other vibrating machines.

![]()

![]()

![]()

Price:$40.00-$500.00/Set

Consult now and enjoy a 10% discount

Model: YZS, YZU, YZO, YZD, VB, JZO

Exciting force: 1-75KN

Power: 0.12-3.7KW

Power frequency: 50Hz

Speed: 1450r/min

Insulation class: Class B

Working mode: continuous (SI)

The altitude does not exceed 1000m, the ambient temperature does not exceed 40°C, and the relative humidity does not exceed 90% (temperature is 25°C), otherwise, reduce power usage

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

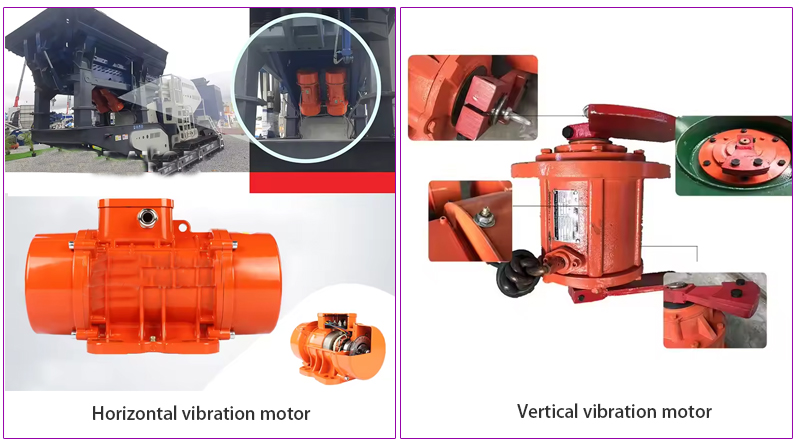

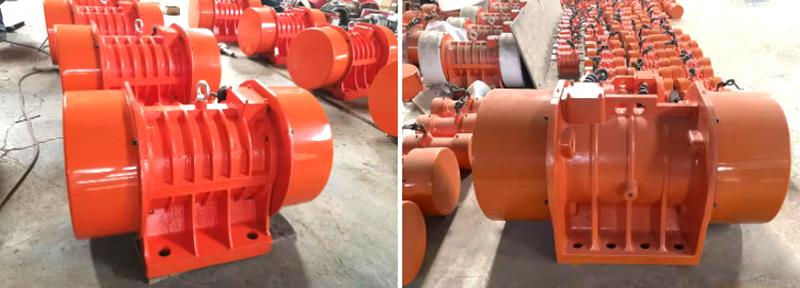

Horizontal vibration motor is to install a set of adjustable eccentric blocks at both ends of the rotor shaft, and use the centrifugal force generated by the high-speed rotation of the shaft and the eccentric blocks to obtain the exciting force. The exciting force can be adjusted steplessly and can be used in general vibration machinery, such as Linear vibrating screen, straight row screen, vibrating crusher, vibrating baler, vertical vibrating hoist, silo wall vibrator, etc.

In addition, various vibration forms can be combined, such as: horizontal type, scroll type, shaking type Vibration type, combined linear type, combined oblong type, compound double frequency type, compound double amplitude type, etc., are widely used in hydropower construction, thermal power generation, construction, building materials, chemical industry, mining, coal, metallurgy, light industry and other industrial sectors.

Horizontal vibration motors are designed to produce horizontal vibrations. In essence, horizontal vibration motors are used to impart controlled vibrations to machinery or materials, which can be beneficial in a variety of industrial processes.They are commonly used in various industrial applications to:

1.Material Handling: Horizontal vibration motors are often used in vibrating equipment such as screens, feeders, and conveyors to facilitate the handling and processing of bulk materials. The vibrations help to separate, classify, or transport materials efficiently.

2.Screening and Sifting: In vibrating screens and sieves, horizontal vibration motors create the necessary vibrations to separate materials based on size, shape, or other characteristics. This is commonly used in industries such as mining, aggregate processing, and food processing.

3.Compaction: Horizontal vibration motors are also used in compactors and vibrating tables to densify and compact materials such as concrete, soil, and powders. The vibrations help to remove air voids and improve the overall density of the material.

4.Feeding and Conveying: Vibrating feeders and conveyors equipped with horizontal vibration motors are used to transport bulk materials from one point to another. The controlled vibrations help to move materials smoothly and evenly along the conveyor or feeder.

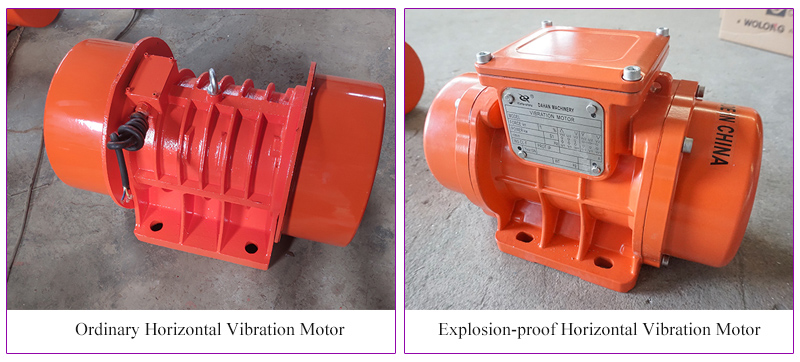

Ordinary Horizontal Vibration Motor: For use in non-hazardous environments and not specifically designed to protect against explosions or fires.

Explosion-proof Horizontal Vibration Motor: It is a motor used in gas environment and dust environment to prevent explosion. The explosion-proof vibration motor has a flameproof structure. When an explosion occurs inside the motor, due to the protection of the flameproof structure, the electric spark will not It will jump out of the motor casing to avoid secondary explosions. It is mainly used in flammable and explosive places.

| Model | Violent vibration | Power(kw) | Current(A) | Vibration frequency(r/min) | Installation size | Weight(Kg) | |||||||||

| (KN) | E | F | G | H | I | L | M | N | n | φd | |||||

| YZU-1.5-2 | 1.5 | 0.12 | 0.36 | 3000 | 130 | 80 | 19 | 80 | 200 | 240 | 164 | 118 | 4 | 12 | 13 |

| YZU-2.5-2 | 2.5 | 0.22 | 0.66 | 130 | 80 | 19 | 80 | 200 | 240 | 164 | 118 | 4 | 12 | 14 | |

| YZU-3-2 | 3 | 0.25 | 0.75 | 150 | 90 | 21 | 90 | 220 | 250 | 185 | 124 | 4 | 14 | 20 | |

| YZU-5-2 | 5 | 0.37 | 1.11 | 150 | 90 | 21 | 90 | 220 | 270 | 185 | 124 | 4 | 14 | 21 | |

| YZU-10-2 | 10 | 0.75 | 2.25 | 180 | 110 | 27 | 112 | 238 | 335 | 225 | 155 | 4 | 18 | 31 | |

| YZU-15-2 | 15 | 1.1 | 3.3 | 220 | 140 | 32 | 125 | 265 | 370 | 272 | 190 | 4 | 22 | 47 | |

| YZU-20-2 | 20 | 1.5 | 4.5 | 260 | 150 | 40 | 140 | 320 | 452 | 344 | 234 | 4 | 26 | 68 | |

| YZU-30-2 | 30 | 2.2 | 6.6 | 310 | 170 | 57 | 170 | 365 | 505 | 400 | 270 | 4 | 33 | 107 | |

| YZU-50-2 | 50 | 3.7 | 11.1 | 350 | 220 | 52 | 200 | 425 | 600 | 450 | 313 | 4 | 39 | 210 | |

| YZU-1.0-4 | 1 | 0.09 | 0.27 | 1500 | 130 | 80 | 19 | 80 | 200 | 245 | 164 | 118 | 4 | 12 | 13 |

| YZU-1.5-4 | 1.5 | 0.12 | 0.36 | 130 | 80 | 19 | 80 | 200 | 240 | 164 | 118 | 4 | 12 | 16 | |

| YZU-3-4 | 3 | 0.18 | 0.54 | 150 | 90 | 21 | 90 | 220 | 260 | 185 | 124 | 4 | 14 | 22 | |

| YZU-5-4 | 5 | 0.25 | 0.75 | 180 | 110 | 27 | 112 | 238 | 335 | 225 | 155 | 4 | 18 | 32 | |

| YZU-10-4 | 10 | 0.55 | 1.65 | 220 | 140 | 32 | 125 | 265 | 370 | 272 | 190 | 4 | 22 | 49 | |

| YZU-15-4 | 15 | 0.75 | 2.25 | 260 | 150 | 42 | 140 | 320 | 452 | 344 | 234 | 4 | 26 | 76 | |

| YZU-20-4 | 20 | 1.1 | 3.3 | 260 | 150 | 42 | 140 | 320 | 452 | 344 | 234 | 4 | 26 | 82 | |

| YZU-30-4 | 30 | 1.5 | 4.5 | 310 | 170 | 57 | 170 | 365 | 505 | 400 | 270 | 4 | 33 | 117 | |

| YZU-50-4 | 50 | 2.2 | 6.6 | 350 | 220 | 33 | 190 | 425 | 600 | 450 | 313 | 4 | 33 | 219 | |

| YZU-75-4 | 75 | 3.7 | 11.1 | 380 | 250 | 35 | 220 | 500 | 670 | 480 | 350 | 4 | 39 | 360 | |

| YZU-1.5-6 | 1.5 | 0.12 | 0.36 | 1000 | 150 | 90 | 21 | 90 | 220 | 270 | 185 | 124 | 4 | 14 | 22 |

| YZU-3-6 | 3 | 0.25 | 0.75 | 180 | 110 | 27 | 112 | 238 | 335 | 225 | 155 | 4 | 18 | 35 | |

| YZU-5-6 | 5 | 0.37 | 1.11 | 220 | 140 | 32 | 125 | 265 | 370 | 272 | 190 | 4 | 22 | 50 | |

| YZU-10-6 | 10 | 0.75 | 2.25 | 260 | 150 | 42 | 140 | 320 | 452 | 344 | 234 | 4 | 26 | 82 | |

| YZU-15-6 | 15 | 1.1 | 3.3 | 310 | 170 | 57 | 170 | 365 | 505 | 400 | 270 | 4 | 33 | 125 | |

| YZU-20-6 | 20 | 1.5 | 4.5 | 310 | 170 | 57 | 170 | 365 | 505 | 400 | 270 | 4 | 33 | 130 | |

| YZU-30-6 | 30 | 2.2 | 6.6 | 350 | 220 | 33 | 190 | 425 | 600 | 450 | 313 | 4 | 39 | 190 | |

| YZU-40-6 | 40 | 3 | 9 | 350 | 220 | 35 | 190 | 425 | 600 | 450 | 313 | 4 | 39 | 190 | |

| YZU-50-6 | 50 | 3.7 | 11.1 | 380 | 250 | 35 | 210 | 465 | 670 | 480 | 350 | 4 | 45 | 300 | |

| YZU-75-6 | 75 | 5.5 | 16.5 | 440 | 250 | 35 | 220 | 500 | 730 | 480 | 350 | 4 | 45 | 400 | |

| YZU-100-6 | 100 | 7.5 | 22.5 | 440 | 280 | 40 | 240 | 550 | 750 | 570 | 450 | 4 | 45 | 420 | |

| YZU-125-6 | 125 | 8.5 | 25.5 | 440 | 280 | 40 | 240 | 550 | 750 | 570 | 450 | 4 | |||

Ambient temperature: no more than 40℃ Altitude: no more than 1000 meters

Power supply voltage: 380V Power supply frequency: 50 Hz

Protection class: IP54 IP55 Connection method: Y or Δ

Insulation class: B, F Working method: S1 (continuous)

Horizontal vibration motor is an excitation source that combines the power source and the vibration source. The vibration motor installs a set of adjustable eccentric blocks at both ends of the rotor shaft, and uses the centrifugal force generated by the high-speed rotation of the shaft and the eccentric block to obtain the excitation force.

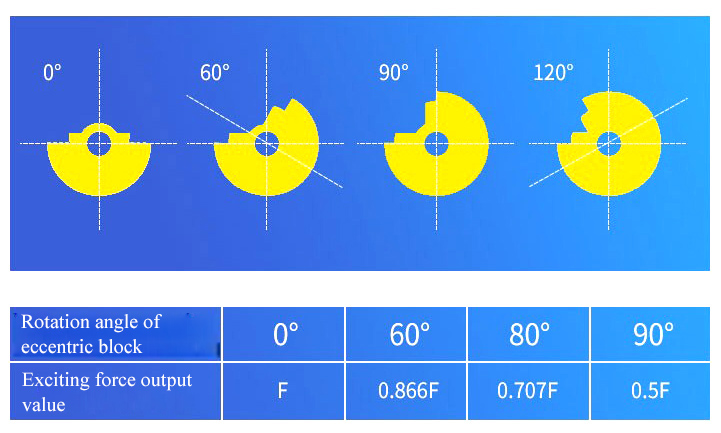

Adjustable vibration direction

By adjusting the position or angle of the eccentric block, the vibration direction, amplitude and frequency can be flexibly controlled.

Clean and hygienic

fully enclosed structure, can work under any dust conditions, no explosion-proof requirements.

Simple structure

It is composed of motor, eccentric block and other basic components. It has a simple structure and is easy to install and maintain.

Stable operation

stable vibration, uniform vibration force, strong load-bearing capacity and long service life.

High efficiency

The vibration force transmission efficiency is high, and it can quickly and effectively realize the transportation, screening and other processes of granular materials.

Multifunctional application

It is widely used in vibrating feeders, vibrating screens, vibrating conveyors and other equipment, and is suitable for a variety of granular material processing processes.

Vertical and horizontal vibration motors are primarily differentiated by their orientation. While both serve similar purposes, their designs and applications can vary significantly.

| Difference | Horizontal vibration motor | Vertical vibration motor |

| Vibration direction | Horizontal | Vertical |

| Vibration amplitude | Large | Small |

| Application range | Large particle materials, large material load | Fine particle material, high screening accuracy |

| Application | Circular vibrating screen, vibrating platform, vertical vibrating elevator | Square vibrating screen, flat screen |

Note: The choice between a vertical or horizontal motor depends on factors such as the specific application, space constraints, and efficiency requirements.

Horizontal vibrating motors can be applied to general vibrating machinery, such as: linear vibrating screens, in-line screens, vibrating platforms, vibrating feeders, vibrating conveyors, vibrating arch-breaking and anti-blocking devices for silos, etc. Horizontal vibrating motors are widely used It is widely used in hydropower construction, thermal power generation, construction, building materials, chemical industry, mining, coal, metallurgy, light industry and other industrial sectors.

1. Determine the vibration frequency and double amplitude of the motor according to the production requirements of the vibration motor and the type of vibrating screen

| Motor stages | Level 2 | Level 4 | Level 6 | Level 8 |

| Vibration frequency r/min | 3000 | 1500 | 1000 | 750 |

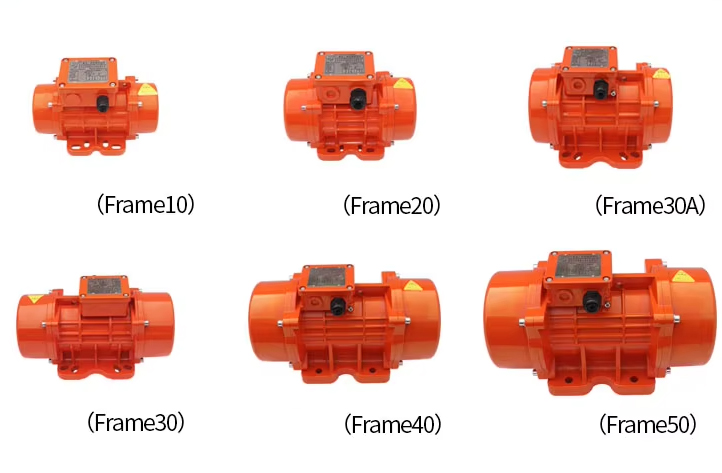

Level 2: the vibration frequency is (N=2870r/min) and the amplitude is (S=2-4mm), which can be used for high-frequency vibrating screen, vibrating platform and other equipment.

Level 4: The vibration frequency is (N=1460r/min) and the amplitude is (S=4-8mm), which can be used for light linear screen, rotary vibrating screen and other equipment.

Level 6: The vibration frequency is (N=980r/min), and the amplitude is (S=8-12mm), which can be used for heavy-duty screening or conveying equipment such as mining vibrating screens.

2. Determine the required excitation force

According to the structure of the vibrating machine itself, obtain the weight G (kg) of the vibration machine, and calculate the required vibration force Fm (N), and then the motor model can be obtained.

Vibration force: Fm=G/g×r×ω2

G: Mass of the eccentric block, g: Gravitational acceleration, r: The distance between the center of mass of the eccentric block and the rotary axis, ω: The rotational angular frequency of the motor

Motor Body: This is the core of the vibration motor and is responsible for generating the rotational force.

Eccentric Block: A heavy block mounted on the motor shaft, which generates centrifugal force by rotation, thus vibrating the entire vibration system. The weight, number and mounting position of the eccentric blocks directly affect the amplitude and frequency of the vibration.

Bearing: Supports the motor rotor and ensures its smooth rotation.

End caps: Seal off the inside of the motor to prevent dust from entering and to support the bearings.

Spring: Installed between the motor and the machine base, it plays the role of damping and vibration isolation to protect the motor and equipment.

1. Remove the protective covers at both ends, and loosen the compression bolts of the adjustable eccentric blocks at both ends;

2. Synchronously adjust the angle between the adjustable eccentric block and the fixed eccentric block at both ends, so that the required excitation force scale line is aligned with the reference line of the shaft end;

3. Tighten the eccentric block pressing bolt and install the protective cover;

4. Check the power supply to see if there is a phase loss, and run it for 5 minutes with no load;

5. Use a 500-volt megger to measure the insulation resistance, and the value should not be lower than 0.5 megohm;

6. Installation of the foot hole of the vibration motor: The four, six or eight foot bolts of the motor should be selected according to the diameter of the corresponding high-strength bolts of not less than 8.8. The length of the bolts is determined according to the installation situation of the user. After 20 minutes, check the bolt tightening torque and tighten again if necessary.

Matters needing attention: When installing the horizontal vibration motor, it must be installed strictly according to the requirements. Generally, it is installed horizontally. If it cannot be installed horizontally, contact the manufacturer to consult the installation angle range. Generally speaking, it cannot exceed 10 degrees. Install it according to the requirements to ensure its use effect.

The main reason for the horizontal vibration of the motor is the design of the eccentric block. In the vibration motor, the eccentric block is installed on the motor shaft. When the motor is running, the eccentric block generates centrifugal force.

This centrifugal force causes the motor to vibrate in the horizontal direction, which is transmitted to the equipment for conveying, screening and other processes of granular materials. By adjusting the position or angle of the eccentric block, the direction, amplitude and frequency of vibration can be controlled to meet different process requirements. Therefore, the fundamental reason for the horizontal vibration of the motor is the vibration effect caused by the centrifugal force of the eccentric block.

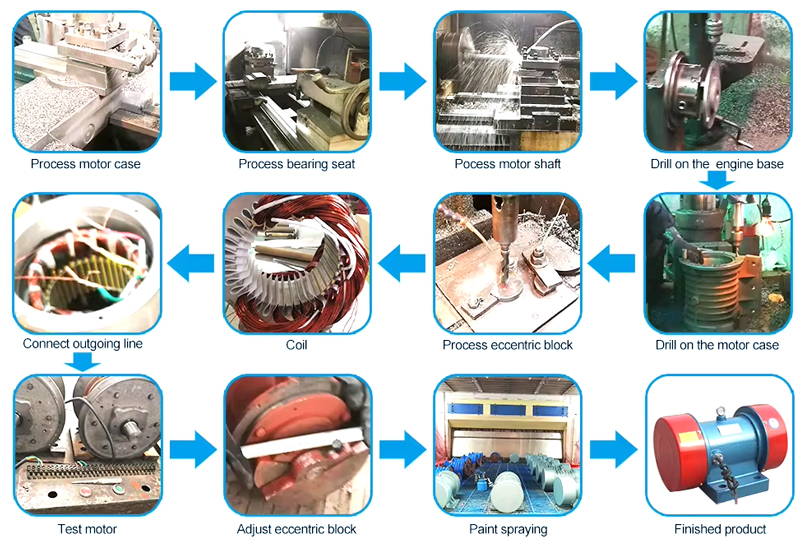

Xinxiang Dahan Vibration Motor Manufacturer has been established for 12 years. The products mainly include: YZUL vertical vibration motor, YZU horizontal vibration motor, explosion-proof vibration motor and warehouse wall vibrator, etc., which can be widely used in linear vibrating screens and rotary vibrating screens. , Straight screen, mining vibrating screen, conveying hoist, vibrating feeder, vibration table and other equipment. The vibration motor is supplied by the original factory, and each process is inspected during the product manufacturing process. Before leaving the factory, it is tested on a comprehensive test bench under full load for 8 hours to ensure various performance parameters. In addition to standard models, our manufacturer can customize various Vibration motors with different installation sizes, different voltages, special insulation levels, and protection levels (such as those used in water). The product can be shipped on the same day, and the warranty period is 6 months. We will take full responsibility for any quality problems.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.