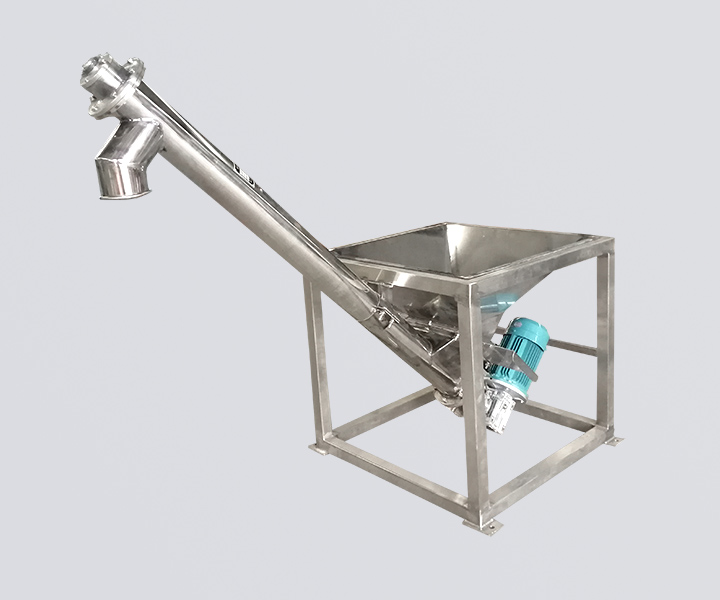

Powder hopper feeder

Powder hopper feeder Flexible powder hopper feeder

Flexible powder hopper feeder Stainless steel powder hopper feeder

Stainless steel powder hopper feeder Vertical powder hopper feeder

Vertical powder hopper feeder Feeding hopper for feeding of bags

Feeding hopper for feeding of bags

Automatically transport the powder of granular materials to the hopper; it can be completed with mixers and special packaging equipment

![]()

![]()

Price:$565.00 - $6,282.00/ Set

Consult now and enjoy a 10% discout

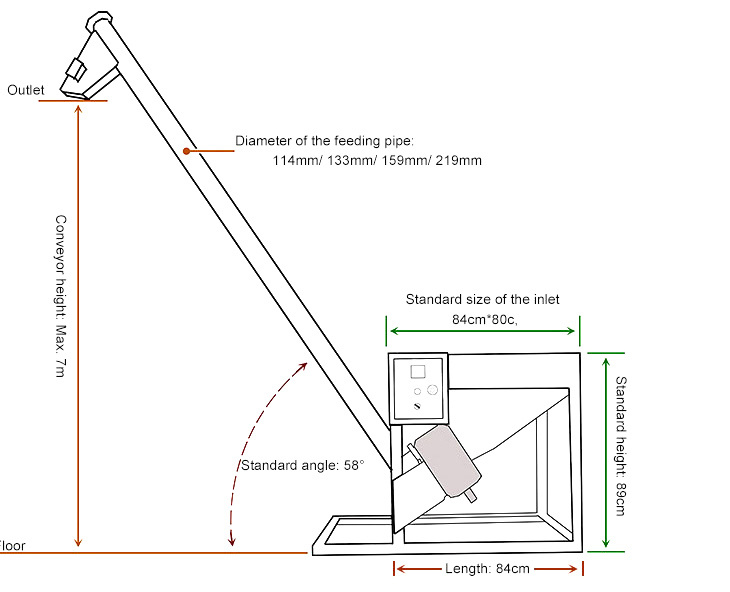

Diameter: 114, 113, 159mm

Hopper volume: 100L

Conveying height: ≤8 meters

Conveying capacity: 1000kg/h Speed: 1450 rpm

Motor power: 1.5KW-6KW

Power supply: three-phase, 220v/240v/380v/415v/440v 50HZ

Application: flour, soybeans, feed, plastic particles, coal powder, muck, cement and other powders and granular materials

Commitment:

Powder hopper feeder is mainly suitable for the transportation and lifting of powdery materials in food, chemical, building materials, plastics and packaging industries, such as flour, starch, miscellaneous grain powder, seasoning, additives, putty powder, mineral powder, etc., and is matched with packaging machines Form a complete set of automatic packaging production line.

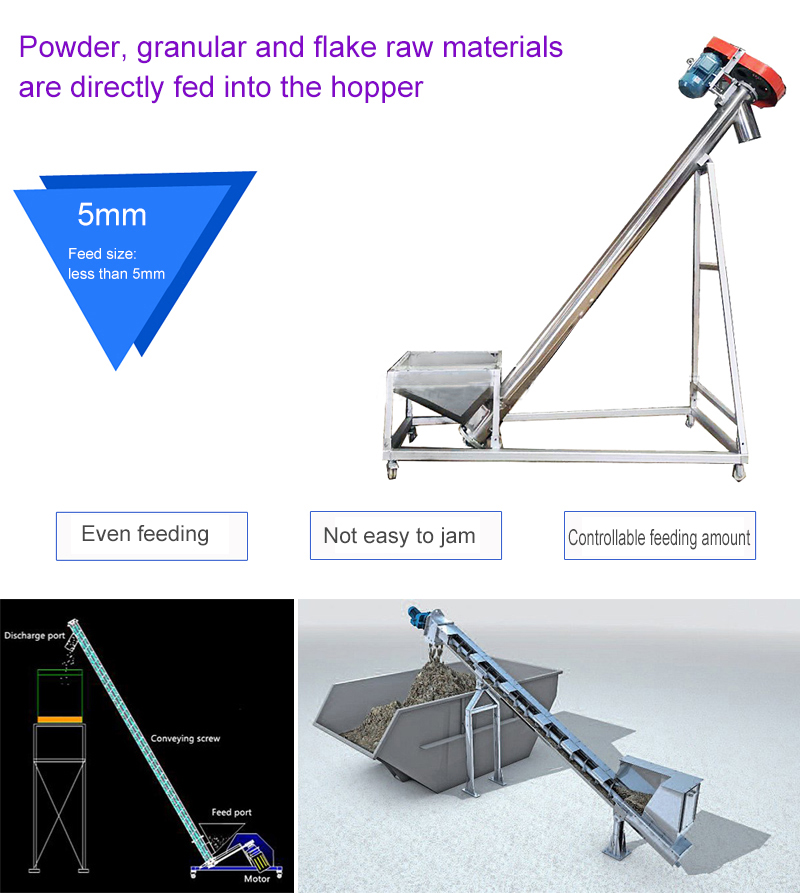

The hopper of the powder hopper feeder is equipped with stainless steel grille to ensure the safety of workers and prevent oversized particles from entering the conveyor. It is mainly used to transport powder and granular materials between slopes. The feeding particle size is less than 5mm. The hopper and conveyor pipes are all made of stainless steel (material According to customer requirements), to ensure that the raw materials are completely pollution-free during the transportation process. The conveying pipeline adopts a closed design, which can effectively prevent dust and effectively isolate materials with high hygiene requirements or strong odors. It has the characteristics of uniformity, good sealing, and no dust pollution. The conveying distance and inclination angle of the inlet and outlet can be customized according to the site or the height of the connected packaging equipment.

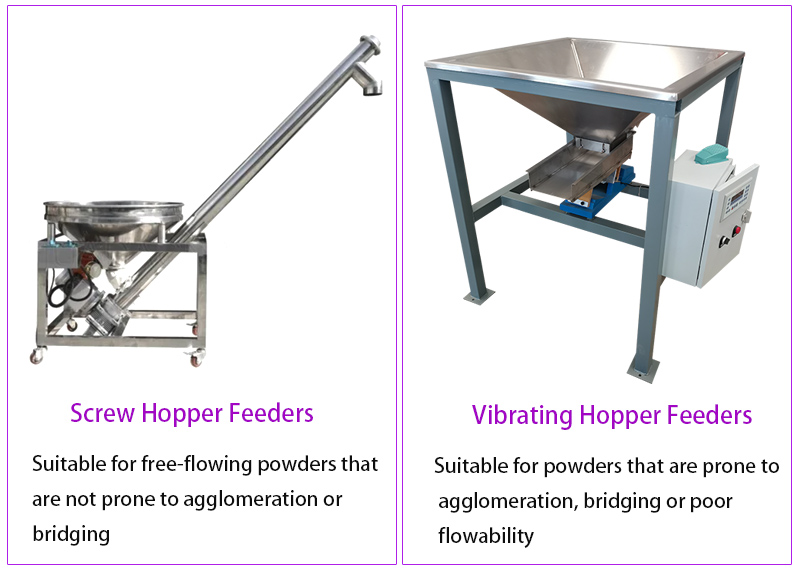

Powder hopper feeders are essentially a combination of a hopper and a feeder mechanism that work together to regulate the flow of powdered materials from the storage hopper to a processing unit. There are various types of powder hopper feeders designed for different functionalities and material properties. Here's a breakdown of some common types:

1.Screw Hopper Feeders:

Function: These feeders utilize a screw auger that rotates within a U-shaped trough to continuously push the powder out of the hopper and into the processing unit.

Suitable for: Screw feeders are a versatile option that can handle a wide range of materials and flow rates. They work well with free-flowing powders that don't clump or bridge easily.

2.Vibrating Hopper Feeders:

Function: These feeders employ vibration to create a fluidized state of the powder within the hopper. This allows the powder to flow more easily out of the hopper by gravity and into the processing unit.

Suitable for: Vibrating hopper feeders are ideal for powders that are prone to caking, bridging, or have poor flow characteristics. The vibration helps to dislodge the powder and maintain consistent flow.

Powder hopper feeder can be used for continuous or intermittent operation, can feed powdered materials, is the choice of users who need to discharge/feed materials from silos or hoppers particularly efficiently, according to the requirements of different industries, single screw and twin screw models are also available, which can convey various powdered products horizontally, inclined and vertically, with a feeding capacity from 500kg/h to 7000kg/h. If multiple mixers use the same material, only one feeder is needed to supply multiple mixers at the same time.

Here's a closer look at the types of powders that are compatible with powder hopper feeders:

| Fine Powders | Fine powders from a few microns to hundreds of microns. These include materials such as flour, sugar, talc, cocoa powder, spices and pharmaceutical powders. |

| Granular Materials | Typically in the 0.1 to 10 mm range, they can also be handled by powder hopper feeders. These include materials such as sand, salt, grains, seeds and plastic pellets. |

| Low-Cohesive Powders | Includes materials such as silica powder, corn starch and baking soda. Low cohesiveness prevents the formation of lumps or bridges that would prevent the smooth flow of powder within the feeder. |

| Non-Abrasive Powders | Designed to handle non-abrasive powders without causing excessive wear or damage to feeder components. |

| Free-Flowing Powders | Particularly suitable for powders that flow well, meaning they offer minimal resistance to movement and flow smoothly without bridging or lumps. |

Metal powder hopper feeder

Powder hopper feeder for conveying flour

Automatic feeding, automatic stop

The powder is continuously poured into the material box, and the switch is turned on. The powder is continuously lifted from the bottom of the material box to the discharge port by the screw. There is a time setting in the system, and the material can be set according to the amount of each feeding. time.

High conveying efficiency

The feeding height of this series of models can reach 2-5 meters, which can be determined according to the user's requirements and the free movement of the working space. The inclined screw feeding can effectively improve the feeding accuracy and avoid the leakage of fluid powder from the screw mouth.

Not easy to accumulate material

It can lift a variety of powder materials. The hopper and screw are made of stainless steel, which is not easy to hang powder.

Easy to clean

The connection between the screw and the hopper and the silo, there is a gate under the hopper, which is convenient for cleaning.

No pollution

Materials in contact with materials are generally made of stainless steel. During the conveying process, the raw materials will not be polluted, and no other impurities will enter.

Not easy for debris to enter

The hopper is equipped with stainless steel grating to ensure worker safety and prevent oversized particles from entering the conveyor.

| Model | Vertical height | Motor power | Feed opening size | Tube length | Transfer speed | Tube diameter |

| LS-1 | 1.8-2.0m | 1.5Kw | 835x800mm | 2623mm | 1000-3000Kg/h | 114mm |

| LS-2 | 2.2-2.4m | 3095mm | ||||

| LS-3 | 2.6-2.8m | 3566mm | ||||

| LS-4 | 3.0-3.2m | 4038mm | ||||

| LS-5 | 3.4-3.6m | 4510mm | ||||

| LS-6 | 3.8-4.0m | 2.2Kw | 4981mm | |||

| LS-7 | 4.2-4.4m | 5453mm | ||||

| LS-8 | 4.6-4.8m | 5924mm | ||||

| LS-9 | 5.0m | 6160mm |

1. When choosing a powder hopper feeder, we should accurately measure the vertical feeding height, the lateral distance from the feed hopper to the discharge port, and the material to be fed, so that the machinery factory can draw up drawings and design the spacing of the paddles inside.

2. The feeding speed of the feeding machine is fast, and it can feed powder, crushed materials, raw materials, etc. or mixed materials. It makes up for the shortcomings of inconvenient powder suction and low output of the suction machine, but it also has some disadvantages, that is, it is not suitable for machines that often need to change colors, because the machine is sealed and welded, so it is not easy to clean. color.

3. Use sealed maintenance-free bearings, fill the bearing seat cavity with grease to prevent dust and impurities from entering the bearing seat, and ensure the normal operation of the machine.

4. In order to prevent metal debris from entering the tube body of the feeding machine, a screen should be added to the feeding port.

Pour the powder raw materials into the material box continuously, turn on the switch, and the product is continuously lifted up from the bottom of the material box by the screw to the discharge port. There is a time setting in the system, and the feeding can be set according to the amount of each feeding. time.

Powder hopper feeder is mainly composed of feeding port, spiral blade, feeding pipe, driving device, discharge port and other parts.

Feeding port: users can choose two shapes of round or square.

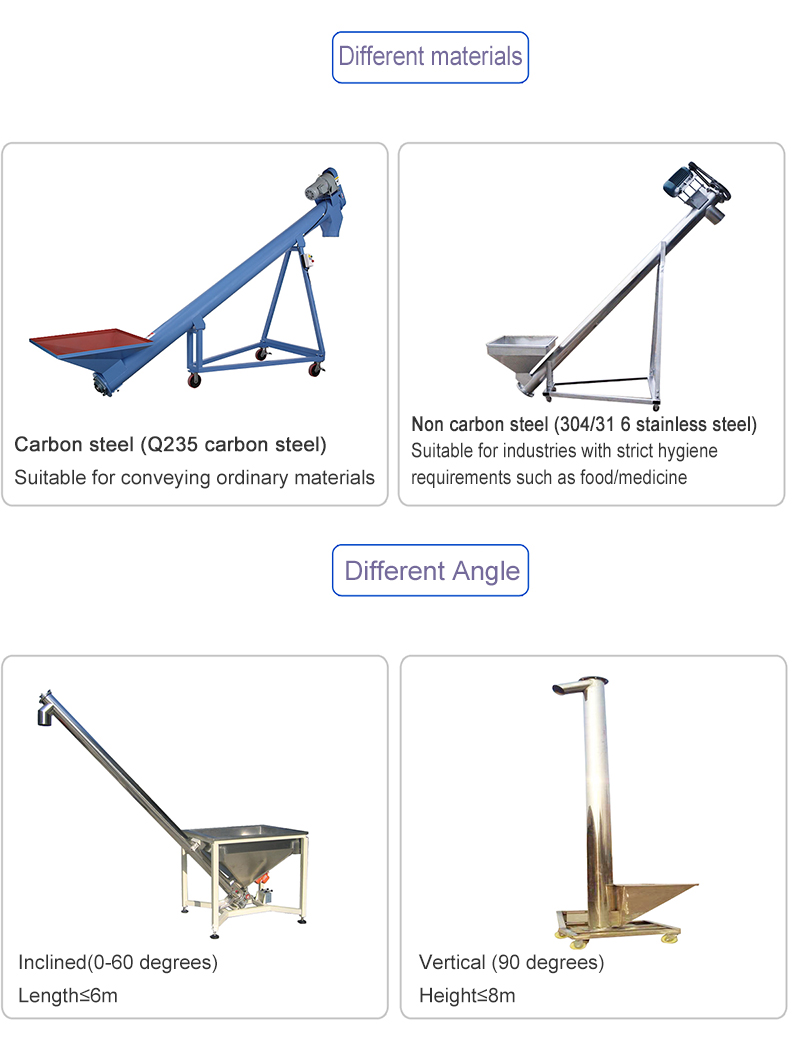

Spiral blade: There are two types of shaft or no shaft according to the conveying material, which are divided into three materials: carbon steel, stainless steel and manganese steel.

Drive device: It consists of motor and reducer. The motor is suitable for 380V, 3-phase, 50Hz, its protection grade is IP55 (outdoor type), and its insulation grade is F grade. It is composed of gear reducer, with large torque, low noise and no oil leakage.

Discharge port: divided into three types: square discharge port, hand-push discharge port, and rack-type discharge port.

Note: The material inlet and outlet can be made into the required inclination angle according to the working site conditions, and it can be connected and fixed with other supporting equipment. Dimensions: determined according to engineering needs. In order to facilitate the cleaning of residual materials, the screw can be reversed for discharge, the lower end of the material tube has a gate for discharging, and the entire screw can be easily disassembled, installed, and cleaned without tools.

Hoppers and feeders are both storage containers used in material handling, but they differ in their primary function:

Hopper: A hopper is a container used to store and dispense bulk materials such as grains, powders, or granular materials.

Feeder: A feeder is a device used to control and regulate the flow of materials from a hopper or storage container to a processing or conveying system.

Powder hopper feeder can be used with various specifications of plastic mixers, mixing mixers, extruders, high-speed mixers, and is widely used in various powder feeding work. The material is continuously lifted up from the bottom of the material box to the discharge port by the screw. There is a time setting in the system, and the feeding time can be set according to the amount of each feeding. The required inclination angle and connection with other equipment is fixed.

A screw feeder uses a rotating screw shaft enclosed in a trough to move solid powders. The screw pushes the powder along the trough, metering it out at a controlled rate from the discharge end. Imagine a long, twisted pipe (screw) turning inside a channel (trough). As the screw rotates, it scoops up powder and pushes it forward, steadily releasing it at the end.

1. Feed arrangement

What is important in the design of a powder hopper feeder is the loading ratio and method of the material, because the capacity and power of the conveyor are generally considered based on the percentage of the selected loading volume (ie, the fill factor). The various loading arrangements are described as follows:

(1) Fixed charging: The screw feeder composed of a specially designed conveying screw sealed in a tubular groove body can enable the material to be output from the silo at a predetermined speed, and the amount of output material has nothing to do with the height of the material.

The rotary impeller feeder adopts a cylindrical rotating impeller with a specific volume on it, and discharges the material at a certain speed. The transmission is driven separately.

(2) Multi-point feeding: It is often required to arrange a conveyor with multi-point feeding, which must be adjusted manually. When only one inlet needs to be opened at any given time, the gate or switchgear should be limited to the maximum opening that does not allow overloading the conveyor. When more than one feed port needs to be opened, the flow rate of each feed port must be carefully adjusted so that the total amount does not exceed the upper design capacity of the conveyor. When multiple feed ports need to be fully opened while feeding the conveyor, the total material flow must be controlled.

(3) Loading from a fixed silo: When the screw conveyor is directly loaded from the fixed silo without the flow adjustment device, the risk of overloading is greatly increased. To this end, an ammeter indicating the load current can be attached to the motor controller, which is a simple and practical way to indicate that the load is reached. This method is especially suitable for occasions where manual operation is used to control the loading of the screw conveyor.

(4) Buffer charging: The product often needs to fall vertically on the folded edge of the conveyor inlet. Due to the inertia of the material block or particle, there will be impact, which may damage or wear the equipment. This can be overcome by installing baffles or buffer chambers in the inlet chute.

2. Unloading arrangement

Standard unloading is one of the most commonly used unloading arrangements. Standard unloading ports are used to restrict the unloading of materials and directly send materials to subsequent equipment or storage devices. The terminal discharge is similar to the standard discharge opening. However, the discharge port is located at the end of the trough body of the screw conveyor, and its end flange is integrated with the end of the trough body.

(1) Discharge port without nozzle: The powder falls directly through an opening at the bottom of the spiral groove. Generally, it is used for unloading in the middle of the device, and there is no need to stop unloading at this point until there is no difference in blanking, for example, it is used to unload to the silo.

(2) Bottom-opening unloading: used for unloading and distributing materials into hoppers, silos or silo stacking. The material is discharged at any required length opening at the bottom of the screw conveyor tank. The materials are piled up to form a natural material pile, and the materials that come one after another are sent to the undischarged place through the material pile.

(3) Discharge at the end of the spiral groove body: The powder is directly discharged through the opening at the end of the groove body of the screw conveyor. The screw is supported by the partial end plate, and the bearing is mounted on the flange at the end. This discharge method cannot be used when the conveyor fill factor exceeds 0.45.

(4) Unloading with open ends: The conveyor tail screw is supported by standard suspension bearings. This form of unloading arrangement can freely unload materials to silos or storage piles and similar places.

Dahan Machinery is a powder hopper feeder manufacturer with 14 years of experience. It has been committed to the design and research and development of screw feeder equipment. It monitors the whole process from design to debugging to ensure the high quality of the equipment and meet the production needs of users. . Our company has passed ISO international quality system certification and EU CE certification, various types of powder hopper feeders are available from stock, and can also be customized according to user needs.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.