Add water and stir during the conveying process, which is convenient for the humidified ash to be transported on a truck or transferred to other conveying equipment

![]()

![]()

![]()

Price:$658.00 - $2,900.00/Set

Consult now and enjoy a 10% discount

Material type: solid liquid, dry powder, granule

Each processing capacity range: 1000-3000L

Diameter of stirring blade: Φ 450-Φ 600nn

Production capacity: 10-200t/h

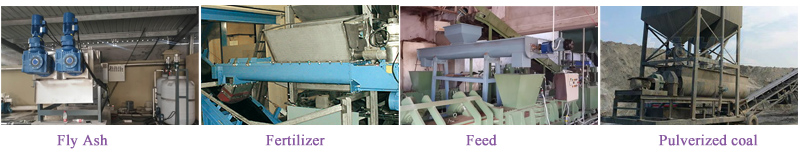

Application: used for mixing and mixing of clay, coal slime, nutrient soil, organic fertilizer, etc. in brick factories

Commitment:

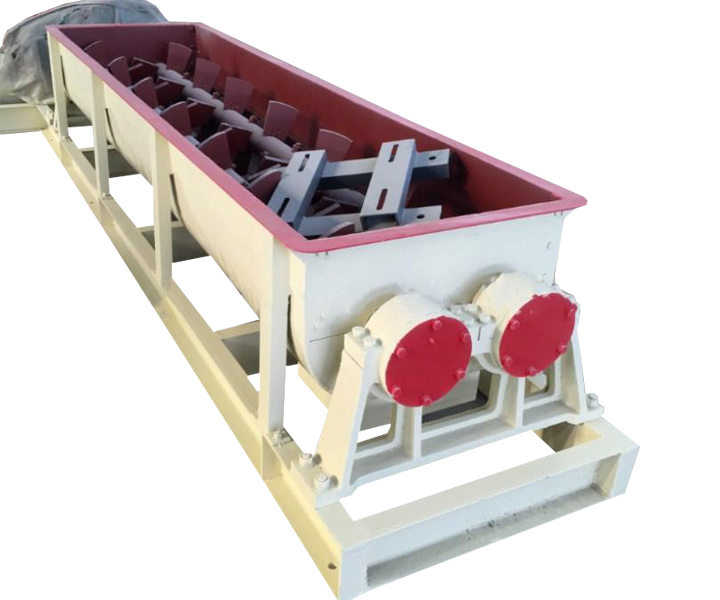

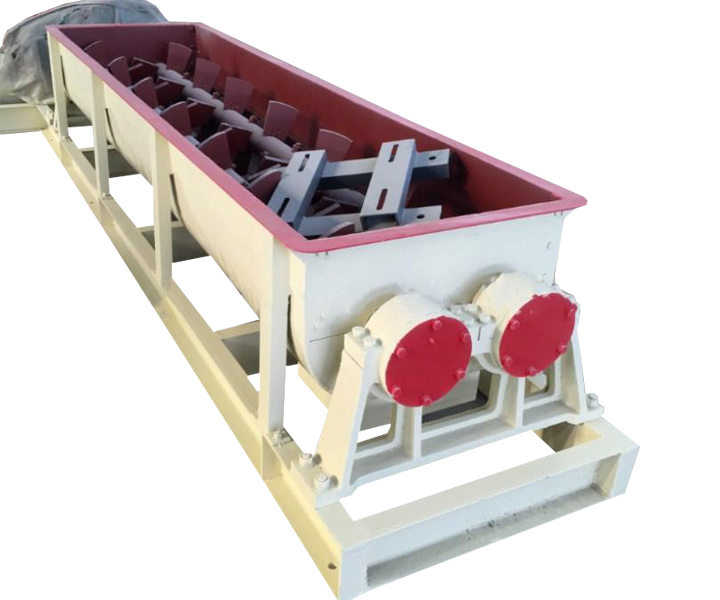

Twin screw mixer utilizes the synchronous rotation of two symmetrical screw shafts to add water and stir while conveying dry ash and other powdery materials to evenly humidify the dry ash powdery materials, so that the humidified materials will not emit dry ash and will not seep out The purpose of water droplets is to facilitate the transportation of humidified ash or transfer to other conveying equipment. It is mainly suitable for the occasions where fly ash or similar materials are humidified and loaded in thermal power plants, mines and other industries.

Twin screw mixer is through the relative rotation of two sets of shafts with spiral blades, adding water to spray, wet, stir and transport powder materials, so that the powder materials can reach controllable humidity. This equipment is mainly suitable for humidification and mixing of raw materials in the fertilizer industry. Make the material fully agitated and compatible with the conveying function.

The twin screw mixer is driven by the motor through the coupling to drive the reducer, which in turn drives the gear pair to run to achieve the opposite movement of the two helical blade shafts. A helical blade is installed on the helical blade shaft, and the helical blade is made of wear-resistant material. The material enters the tank through the feeding port, and is agitated and crushed by the spiral blade, and the material is discharged from the discharge port after the material has a uniform particle size.

Good mixing effect

Twin screw mixer adopts two sets of spiral blades for stirring, which has high stirring efficiency and is suitable for humidifying and stirring of fly ash in power plants. The mixed fly ash has no dust pollution during transportation, loading and unloading.

Spray evenly

The equipment is equipped with a humidification water spray system to ensure uniform water spray, which can realize continuous disturbance and automatic dredging of fly ash deposition or blockage in the pipeline, with high conveying concentration, low flow rate and small wear.

Tight seal

The equipment feeds from the top and discharges from the bottom, and the sealing between the joint surfaces of the double-shaft humidifying mixer is tight.

Low noise

The equipment is driven by a cycloidal pinwheel reducer, with stable rotation and low noise.

| Double shaft horizontal mixer model | HDWJ2000 | HDWJ2500 | HDWJ3000 |

| production capacity(t/h) | 8 | 10 | 18 |

| Spindle speed(r/min) | 35 | 35 | 35 |

| motor(kw) | 7.5KW4class | 11KW4class | 15KW4class |

| Dimensions (L×W×H) |

3100×750×500 | 4200×800×620 | 4700×800×620 |

| equipment weight(kg) | 1600 | 2500 | 3200 |

Twin screw mixer mainly consists of driving device, feed port screw shaft, tank body, discharge port and other parts.

1. The shell is mainly composed of plate and section steel, which is welded and formed in the manufacturing plant and assembled with other components, which is the support of the double-shaft mixer. The shell is tightly sealed, and there will be no phenomenon of flying ash and ash leakage.

2. The screw shaft assembly is the main component of the double shaft mixer, and its components mainly include left and right rotating screw shaft, bearing seat, bearing sleeve, bearing cover, gear, sprocket, oil cup, blade and other parts.

The left-right-handed screw shaft requires high manufacturing precision and good process performance, and has strict matching requirements with the bearing seat, bearing sleeve and bearing cover. The gear module is 8, the number of teeth is 60, and the tooth profile angle is 20°; the sprocket pitch is 50.8, the number of teeth is 25, and the tooth profile is GB1224-85. Gears and sprockets are protected by protective covers for safe and effective operation. The oil cup is a press-fit pressure filling oil cup, which is convenient and effective to add lubricating oil. The material of the double-shaft mixer blade is made of composite ceramics that are wear-resistant and not easy to stick to ash. The design of the blade structure is reasonable and simple, and it is easy to replace after wear and has a long service life.

3. The piping for adding water and humidity control is mainly composed of connecting pipes, joints and nozzles. The nozzle adopts stainless steel atomizing cone nozzle, which is arranged above the inside of the mixer casing and is axially arranged along the direction of the screw shaft to form a water curtain to facilitate the humidification and stirring of the material. The nozzle structure is simple, easy to replace, stainless steel, anti-corrosion and durable. The moisture content of the wet ash can be adjusted by operating the manual regulating valve on the water supply line.

4. Covers mainly include left cover, middle cover, right cover, hole cover and manhole cover. There are six inspection holes on both sides of the double-shaft mixer to facilitate the operator's usual inspection and maintenance. Twin shaft mixers are used at the end of pneumatic conveying.

To handle complex conveying situations, the Twin Screw Mixer is available in a variety of different designs, such as:

Multiple inlets and outlets

flange connection ring

Special materials (carbon steel, stainless steel, manganese steel, etc.)

Special paddle shapes (ribbon, solid, toothed, paddle)

Special motor (waterproof, explosion-proof, adjustable speed)

Different power sources (single-phase, three-phase)

Sprayer location (top or machine side wall)

This is a real customer case. A friend chose us after a long period of comparison and selection.

This customer needs to use the Twin Screw Mixer to process some organic waste and needs to use a spray device to spray some solvents during the mixing process, and needs to control the mixing and output time within 5 minutes.

In the face of this customer's request, we have designed the Twin Screw Mixer with an adjustable speed for practical use, so as to facilitate the effective mixing of organic waste and solvents in a timely manner under different circumstances, and the customer can adjust the speed according to the actual situation. The need to control the mixing time of organic matter.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.