Wet sieve test

Wet sieve test Wet sieve analysis

Wet sieve analysis Wet sieve

Wet sieve Wet test sieving

Wet test sieving Wet sieving

Wet sieving

Use water to help separate and sieve particles that are agglomerated or stuck together

International standard: ISO3310-1:1990 R20/3, R20, R40/3 series

Price:$24.00 - $200.00/Piece

Consult now and enjoy a 10% discount

Diameters: 3", 8", 12"

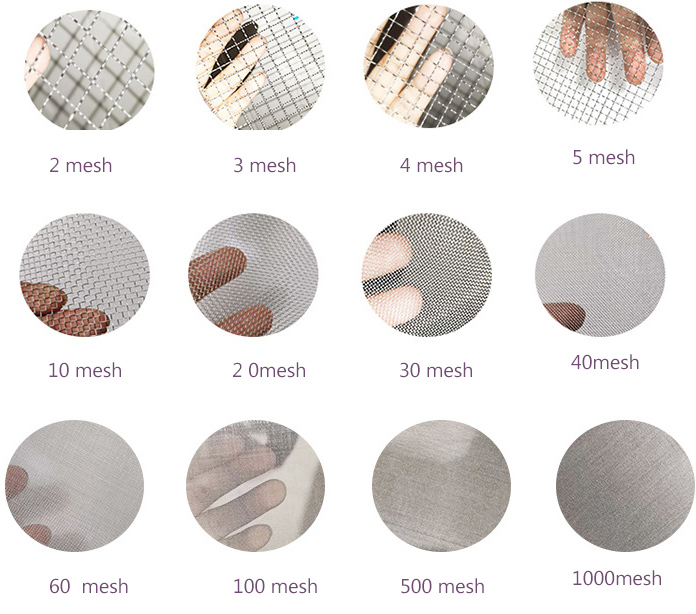

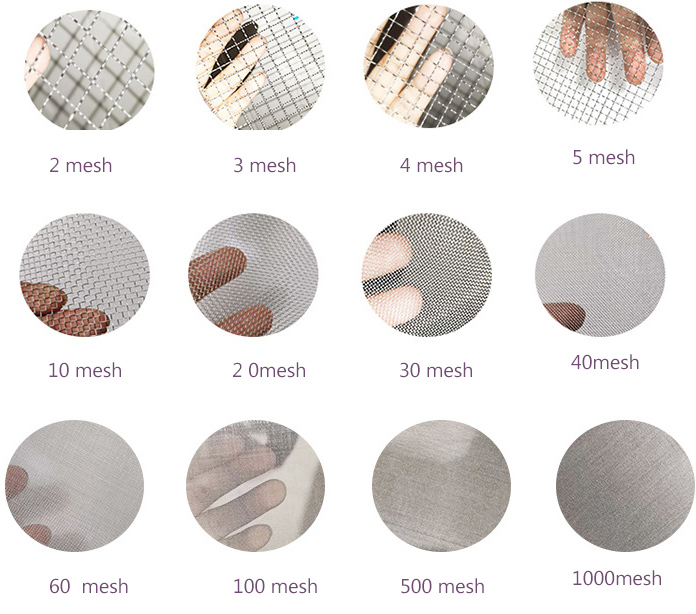

Mesh size: 20 microns-5 mm

Height: 4 inches, 8 inches

Material: stainless steel, brass

Application: Suitable for wet processing, where high concentrations of fine particles tend to stick together and will not separate using only mechanical shaking, such as aggregates, clays, slurries, silts, etc.

Commitment:

Wet sieve test is a method of separating crude material with water or other type of liquid prior to drying, identification and analysis. This is a method that can be used to prepare samples, such as removing fines, breaking up clumps, or eliminating static charges. During this process, the sample is washed through a sieve set. A sieve can be used for simultaneous sieving and washing.

We offer 8" (200mm equivalent) diameter screens with brass or stainless steel frames. These screens are available in 4" and 8" deep, with mesh sizes ranging from 20 microns to 5 inches.

If the material is subject to electrostatic charges, the particles can easily stick together and fail to pass through the proper openings. Other properties can cause the particles to agglomerate or clump together, which restricts the particles from breaking through the proper openings. There is also a third problem of separating the particles so that they can pass through the appropriate openings: the problem of individual particles sticking together.

A process called a wet sieve test can be used to solve most of these problems. The sample is suspended in an aqueous solution, eliminating static charges, breaking up clumps, and lubricating close-to-size particles.

The solution is washed through a high-walled screen with appropriate openings. The residue on each sieve was dried and reweighed for separation and particle size distribution calculation.

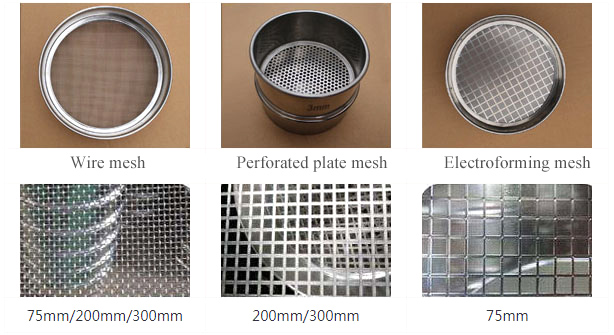

Wet sieve test of woven wire mesh: It is widely used, with meshes ranging from 2.36 mm to 0.02 mm, with only square meshes.

Punching plate wet sieve test: The mesh has uniform precision and is not easy to deform. It is mainly used for the detection of large particles. Since there are two types of round holes and square holes, it is used such as round hole asphalt collection sieve and round hole coal sample sieve.

Electroforming wet sieve test: It is manufactured by electrochemical method and has high precision. Theoretically, the precision can reach one micron. However, due to the different process molds of the manufacturers, there will be great differences. At the same time, the flexibility is not good, easy to crack, and the cost is too high. Not applicable for production.

1. The whole machine is exquisitely designed, light weight, small in size, and convenient to place and move.

2. It has a wide range of applications and can be used for particle size classification and particle size analysis of slurries and powders.

3. The screening accuracy is accurate and the efficiency is high, and it can be screened to 0.025-3mm.

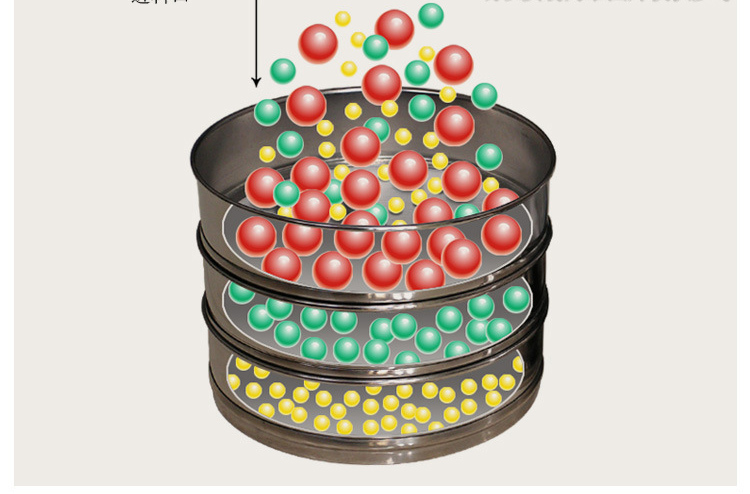

4. There are many classifications of materials, and 8 particle segments can be accurately separated at the same time.

5. The sieving time can be set by yourself, and it will automatically shut down. The time is adjustable from 1s to 99h to ensure the repeatability and consistency of the experiment.

Wet sieve test uses the YZU vertical vibration motor as the vibration source of the whole machine. The vibration motor drives the upper vibrating plate to vibrate, and then transmits the vibration through the vibrating plate to the screen frame on the upper part of the vibrating plate . The material particles with the sieve aperture are sieved to the lower sieve frame, so that only materials of the same particle size are left in each test sieve to achieve the separation of different particle sizes and determine the particle size composition of this material. The materials can be very effective for filtering, grading and screening purposes.

| NO. | Name | Unit | Parameter |

| 1 | frame diameter | mm | φ200 |

| 2 | the number of layer | s | 1~8 |

| 3 | sieve size | mm | 0.025-3 |

| 4 | vibrating amplitube | mm | 1~4 |

| 5 | vibration frequency | n/min | 1440 |

| 6 | power supply | V;HZ;KW | 220;50;0.12 |

| 7 | outside dimension | LWH | 350*350*(300+n*56) |

| 8 | machine weight | kg | 36 |

| 9 | time alarm | s | 999 |

| 10 | noise | db | Less than 50 |

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 70# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

Chemical industry: resin, coating, medicine, medicine, cosmetics, fire-extinguishing agent, plastic powder, abrasive glass, etc.

Ceramic industry: abrasives, alumina, porcelain mud, clay mud, glass powder, refractory materials, quartz sand, PVC resin powder, citric acid, polyethylene powder, washing powder, etc.

Food industry: sugar, monosodium glutamate powder, salt, fruit juice, starch, milk powder, food, soy milk, egg powder, rice noodles, soy sauce, fish meal, pineapple juice, etc.

Metallurgical industry: carbon black, cosolvent, activated carbon, pearls, etc.

Pre-testing

Mix sample materials with water until it becomes a suspension

Prepare a stack of sieves that are drenched

Place gaskets between each individual sieve

Place wet washing lid on the top of the sieves and wet washing receiver (with outlet) on the bottom

Establish the flow of water

Wet Sieving

Pour the materials onto the top sieve

Turn on the sieve shaker for 5-10 minutes depending on the size of the sample

Turn on the water supply

Observe the liquid from outlet and turn off the water and shaker once the liquid is clear

Collect materials that retained on each sieve

Use the oven to dry the material, after drying, materials need to be weighed for data analysis

Address:China,Yanjin county forest park gate to the west 1000 meters north road.