Activated carbon has been hot in the market in recent years. Common activated carbon states are roughly four types: sphere, cylinder, granular and powder. If activated carbon is to be sieved, it is recommended to select different sieving equipment for different shapes of activated carbon to achieve the best results. Choosing appropriate sieving equipment can effectively handle the particle size and shape differences of activated carbon, improve screening efficiency, reduce energy consumption, thereby achieving efficient operation and optimization of the production process.

However, no matter what type of activated carbon vibrating sieve, the principle of vibration sieving is generally used to screen and separate activated carbon particles according to size through the vibrating sieve to remove impurities and irregular particles and improve the quality and purity of activated carbon products.

Cylinder, spherical, granular activated carbon production process:

Coal/Charcoal---Pretreatment---Carbonization---Crushing---Pelletizing---Sifting---Packing

Granular activated carbon particle size: 0.1mm-12mm

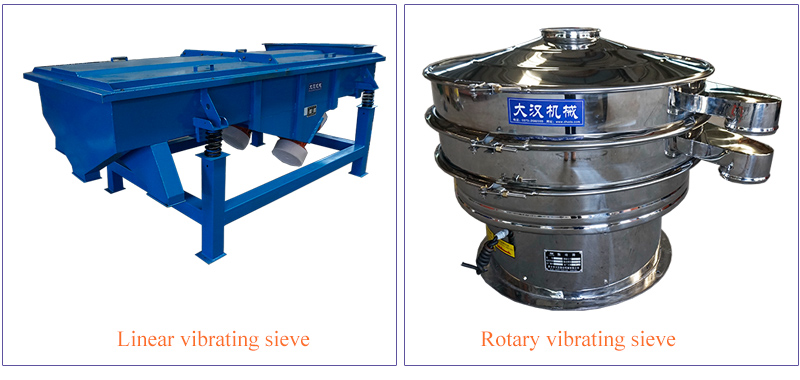

Linear vibrating sieve is a coarse sieve among fine sieves. While the sieveing accuracy is relatively high, the sieveing output is also very considerable, up to 20t/h. Linear vibrating sieve has advantages in processing granular materials.

Cylinder, spherical and granular activated carbon choose linear vibrating sieve, which can remove damaged particles, activated carbon dust, etc. in formed activated carbon, ensure product quality and uniform specifications, and activated carbon linear vibrating sieve can also meet the output requirements of activated carbon production line, special customized models The output of the linear sieve can reach 60t/h, and it can be connected to the pulverizer, granulator and packaging machine to realize the 24-hour assembly line work of activated carbon.

Compared with the linear vibrating sieve, the output of the rotary vibrating sieve is relatively small when dealing with activated carbon particles, but the precision is higher.

powdered activated carbon

Coconut shell/fruit shell/charcoal—pretreatment—grinding—charring—activating—cooling—grinding—sieveing—packaging—finished product

Powdered activated carbon particle size: 50-300 mesh

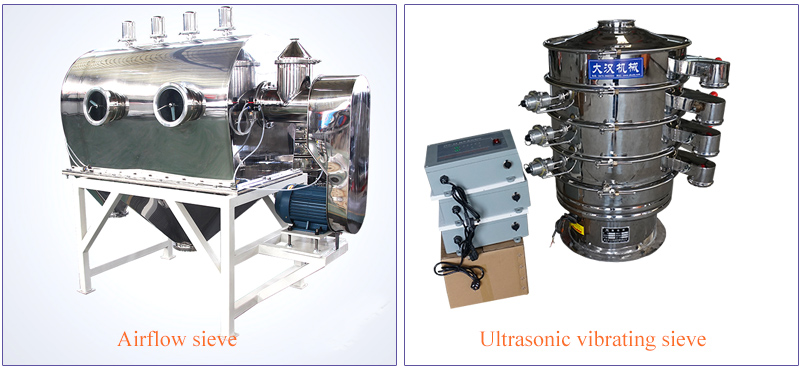

Powdered activated carbon is light and fine, and the sieveing effect of ordinary vibrating sieve equipment is poor.

The ultrasonic vibrating sieve is equipped with an ultrasonic system, which can generate 36,000 times/min of high-frequency vibration, which can make the activated carbon powder pass through the mesh quickly without static electricity and non-sticking. Compared with the ordinary vibrating sieve, the output can be increased by 2-5 times.

And fully sealed design and explosion-proof motor, production is safer.

The airflow sieve is different from the vibrating sieve. The special wind system can spray the activated carbon powder that meets the specifications through the sieve, with high efficiency and large output (up to 12 tons/hour), the activated carbon powder has a higher rate of contact with the sieve, and the sieveing is more fine.

Activated carbon can remove powder and impurities, and has good particle size classification effect, which can ensure uniform specifications of activated carbon after sieveing;

Fully sealed design to avoid carbon powder flying during the sieveing process;

The operation is simple, and it can be sieveed with the activated carbon production line.

The above is a brief introduction to the activated carbon vibrating sieve type. Different screening equipment is selected because each shape of activated carbon has unique physical properties and screening requirements. If you want to learn more about our screening equipment, please click on the online chat on the page to contact me. I believe there will be a screening equipment suitable for you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.