Cement powder Screw conveyors are commonly used powder conveying equipment in cement production. Their design takes into account the characteristics of cement powder, such as its tendency to generate dust and its high fluidity. The equipment is generally made of wear-resistant carbon steel or 304 stainless steel. In some high-temperature applications, a wear-resistant alloy coating is added to the inner wall to reduce the abrasiveness of the cement powder. The conveying capacity can be adjusted according to the production line needs, commonly ranging from 10 to 500 m³/h, adaptable to different scales of cement processes. The common conveying distance is 2 to 30 meters, and the inclination angle is generally not recommended to exceed 20 degrees. For larger angles, special types of spiral blades are required, with pipe diameters typically between 150 and 600 mm, preventing cement powder from clogging the conveyor during operation.

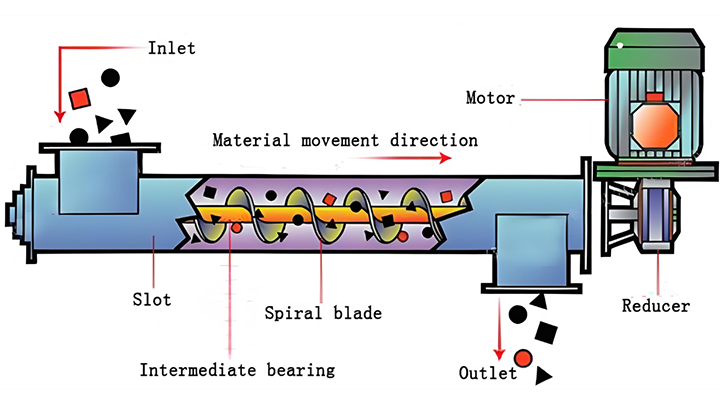

The overall shape of the cement powder screw conveyor is a horizontal or inclined tubular or trough-like structure, enclosed in a sealed casing, with end caps and bearing seats at both ends. The equipment features an internal shaft with continuously welded spiral blades. Larger diameter models are segmented for easier installation and disassembly. The blades are typically made of thickened, wear-resistant carbon steel, and the casing is constructed from bent and welded steel plates with a similarly wear-resistant inner wall treatment, extending its service life. A variable frequency motor at the drive end allows for speed adjustment based on operating conditions, ensuring smoother material feeding. The entire machine has a closed structure with tight connections between the inlet and outlet. Cleaning ports are located at the bottom and ends of the casing, simplifying cement powder removal after shutdown. During operation, the motor drives the spiral shaft, and the blades propel the cement powder forward along the casing, completing the conveying process.

Using a Cement Powder Screw Conveyor to convey cement powder offers several advantages. The fully enclosed structure prevents dust scattering, resulting in a cleaner production environment and reduced cement powder waste, thereby lowering production costs. The equipment operates stably, has a simple structure, few vulnerable parts, requires minimal daily maintenance, and has a low failure rate, making it suitable for 24-hour continuous operation of cement production lines. During conveying, a variable frequency motor can be used to adjust the speed, allowing for continuous adjustment of the conveying capacity. This ensures it keeps pace with upstream batching and synchronizes with downstream processing, resulting in smoother operation of the cement powder production line. In terms of installation, the equipment is compact and lightweight, requiring simple foundation construction. It can be installed horizontally, at an incline, or vertically at a slight angle, easily integrating into cement production lines with different layouts. It also exhibits good material adaptability, smoothly conveying both ordinary silicate cement powder and admixtures such as fly ash and slag powder without easily causing clumping or stratification, ensuring stable powder quality and facilitating subsequent processing.

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

Cement powder screw conveyors are widely used in cement production, including in clinker grinding, cement grinding, batching and mixing, and finished product silo conveying. In a cement grinding station with an annual production capacity of 5 million tons, multiple screw conveyors are used to transport the finished cement from the cement mill to the storage silo. In this case, a tubular screw conveyor with a diameter of 350mm, a length of 25 meters, and an inclination angle of 10 degrees was selected, capable of conveying approximately 120 tons of cement per hour, successfully meeting the requirements for long-distance and high-volume conveying.

Cement powder screw conveyors can be placed horizontally on the ground or on supports, or inclined to connect silos and processing equipment. When installed vertically, the conveying distance is generally no more than 5 meters. In the production process, it can be used for conveying clinker after grinding, transferring finished cement powder, conveying admixtures at batching stations, or feeding finished product silos to loading docks, covering the entire process of powder preparation, batching, storage, and warehousing. The equipment offers flexible upstream and downstream compatibility. Upstream, it can connect to silos, mills, and mixers; downstream, it can connect to elevators, packaging machines, and loading machines. It can also be equipped with auxiliary equipment such as dust collectors, level gauges, or frequency converters to form a complete conveying system, making production line operation smoother and reducing manual intervention.

The Cement Powder Screw Conveyor is designed to fit the characteristics of cement powder, featuring a simple and durable structure, making it a commonly used conveying device in cement production. It solves problems such as dust generation, blockage, and stratification during powder conveying. Installation is flexible, the conveying capacity is adjustable, and daily maintenance is simple. Whether in large-scale cement plants with tens of thousands of tons of capacity or small and medium-sized processing plants; whether for short-distance transport within the workshop or inclined conveying between silos and equipment, this equipment operates stably. It can also be used in conjunction with other cement production equipment to form a complete conveying system, helping to make production smoother and product quality more consistent.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.