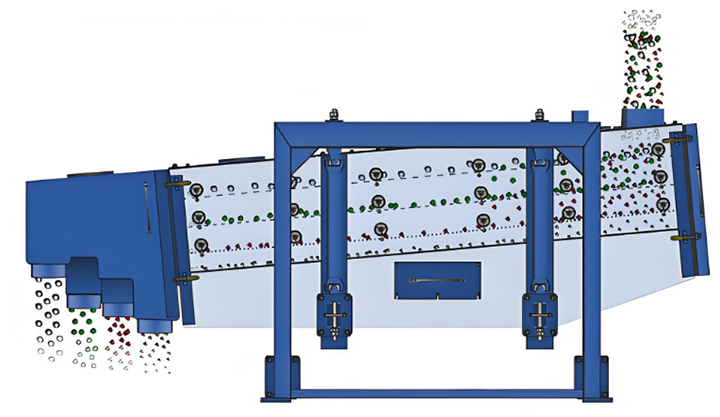

Cereals Square Tumbler Screen can screen grains in a single or multi-layer configuration. During the screening process, the Square Tumbler Screen features an automatic cleaning system, where a flexible ball tray or rotating brush continuously strikes the bottom of the screen to remove any clogged particles. The screens are available in a range of mesh sizes from 4 to 80, allowing for a wide range of throughput capacities from 500 kg to 10 tons per hour. The standard three-layer STJ-800 model can process wheat at a rate of 4-5 tons per hour. Adjustable spindle eccentricity and oscillation frequency allow for precise adaptation to varying capacity and accuracy requirements.

In grain screening systems, single-layer screening primarily serves as a basic pre-processing step. Using a large-aperture screen with a mesh size of 4-12, the screen rapidly removes impurities larger than the target grain, such as straw, stones, hulls, and foreign grains, completing the initial purification process. The multi-layer screening mechanism stacks 3 to 8 layers of precision screens to create a continuous grading channel, achieving precise separation based on the geometric size of grain particles. The first layer of screens, with 6-10 mesh, intercepts residual impurities. The middle 2-5 layers of screens, with 12-30 mesh, form the core grading zone, separating the main grains into different commercial grades, such as extra-large, standard, and small/medium grains. The bottom layer of fine screens, with 40-80 mesh, intercepts damaged grains and fine dust. This tiered process is particularly suitable for optimizing wheat flour yield, grading rice whiteness, separating corn germ, and improving the purity of oats and quinoa.

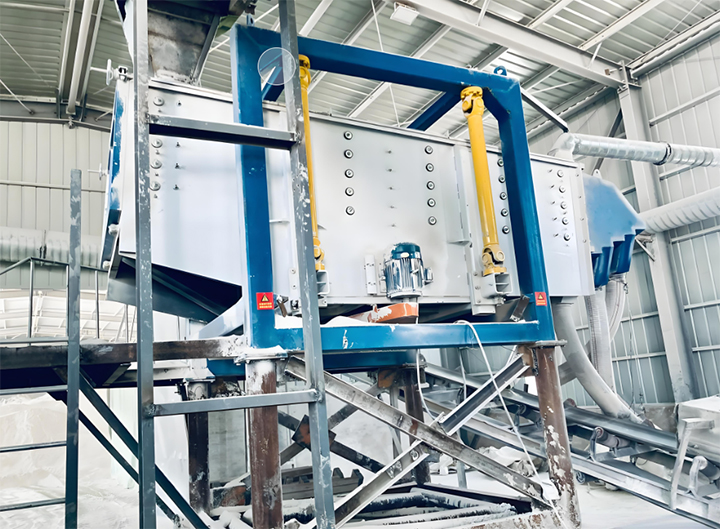

Cereals Square Tumbler Screen can be made of either 304 or 316 stainless steel for grain screening. Its polished interior and minimal crevices prevent cross-contamination and facilitate cleaning. Its enclosed design further reduces dust emissions. At the infeed stage, the equipment seamlessly integrates with a variety of conveying systems: a vertical screw conveyor for short-distance lifting, a bucket elevator for vertical conveying up to 10 meters, and a Z-type bucket elevator for multi-angle feeding in complex spaces. All three systems utilize the same standard metal materials as the main unit to ensure consistent hygiene throughout the entire process. The automated cleaning system at the core of the screening process ensures continuous operation through a three-dimensional synergy. Food-grade silicone balls bounce 20-30 times per second within a specially designed ball-receiving plate, generating vertical shock waves to dislodge trapped particles. Synchronously, a nylon rotating brush reciprocates radially along the bottom of the screen. Its 0.2mm ultra-fine bristles penetrate deep into the base of the screen holes to remove oily deposits, completely eliminating the problem of damp grain clogging the screen holes.

Cereals Square Tumbler Screen utilizes a precisely balanced dual vibrator system located on the top and sides of the machine to create a smooth, yet effective, spreading and stratifying effect on the grain bed as it moves across the multi-layered screen surface. Unlike traditional vibrating screens that rely on violent shaking, the gentle action of the drum screen significantly reduces grain damage and degradation, ensuring consistent stability during long-term operation. The multi-layer screen features a quick-release mechanism, allowing all five screen layers to be replaced within three minutes. Combined with the modular design of the 304 stainless steel screen frame, it can be flexibly configured with screens ranging from 4 to 100 mesh, simultaneously achieving multiple process objectives such as impurity removal, particle size grading, and seed selection in a single pass.

Cereals Square Tumbler Screen's modular design allows it to be integrated with a bucket elevator, screw feeder, and airflow dust removal system to create an automated production line, achieving five-dimensional precision grading of wheat, rice, corn, oats, and quinoa. In rice processing, the device can be configured with 6-8 mesh screens to separate unhulled grains, a 20-24 mesh screen layer to extract whole polished rice, and a 28-32 mesh bottom screen to remove broken rice, increasing the whole rice yield to over 88%. Its fully sealed stainless steel structure, combined with the CIP online cleaning system, effectively controls microbial cross-contamination. The mirror polishing treatment of the interior of the screen body with Ra ≤ 0.8μm ensures zero material residue. The professionally designed dual-mass vibration system produces a low-amplitude three-dimensional rocking motion, which can control the crushing rate to ≤ 0.35% when processing highly brittle oats and quinoa, while maintaining an adjustable processing capacity of 2-8 tons per hour. The integrated system monitors the screening efficiency and equipment operating conditions in real time through the PLC central control module. All contact parts meet FDA certification standards, providing modern grain processing centers with a complete HACCP compliance solution from initial cleaning and grading to finished product packaging.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.