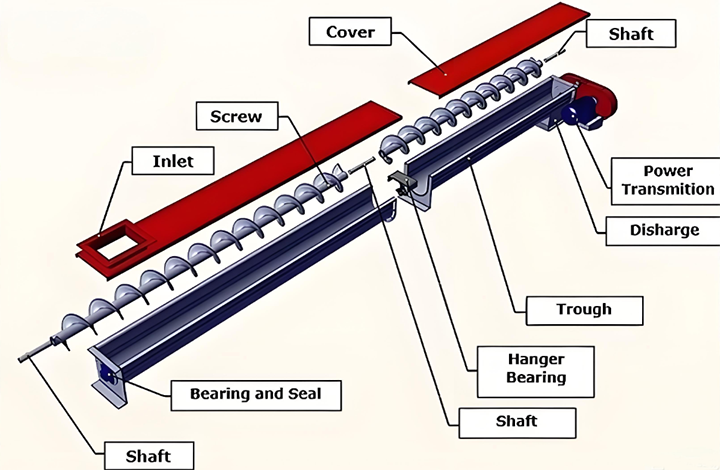

Clay Shaftless Screw Conveyor is suitable for conveying clay with high moisture content and viscosity, reducing the risk of clogging and ensuring smooth operation. It is available in carbon steel Q235 or stainless steel 304 or 316L for enhanced corrosion resistance. The spiral blades are typically 5-10mm thick, and the trough can be lined with plastic, rubber, or cast stone for extended service life. A single unit can convey 10-45 cubic meters of clay per hour, offering smoother material flow than shafted structures for the same diameter, with a maximum conveying distance of approximately 60 meters. It can be directly integrated with crushing, mixing, and molding processes, reducing manual intervention and ensuring smoother production line integration.

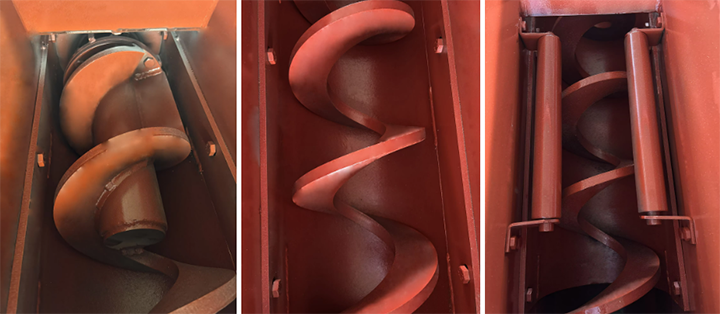

The Clay Shaftless Screw Conveyor utilizes a shaftless structure. Compared to shafted screw conveyors, it lacks a central shaft, preventing tangled clay during operation and reducing clogging issues. The single-piece helical blade is molded in one piece, directly propelling the material forward during operation, resulting in more concentrated thrust and smoother material flow. When conveying clay with high moisture content, the larger central space allows moisture to flow naturally between the blades and the trough, preventing material clumping caused by moisture accumulation. It also prevents strip or sheet-like clay from easily getting stuck inside the equipment; the open structure breaks up entanglements, allowing for continuous forward conveying.

The Clay Shaftless Screw Conveyor is easy to use. Without a central shaft, it solves the problems of high-moisture clay adhesion and strip-like clay entanglement, resulting in smoother material flow and fewer downtimes for cleaning. The machine has no complex parts; routine maintenance only requires periodic checks of the helical blades and trough lining for easy replacement without frequent disassembly. The fully enclosed trough design prevents clay leakage and odor spread, resulting in a cleaner appearance and reduced cleaning workload. The equipment operates at a lower speed, ensuring smooth operation and lower power consumption compared to shaft-type structures. In terms of installation, it can be installed horizontally or at a slight angle. The length and inlet/outlet positions can be customized to meet production line requirements, making integration with existing production lines seamless and ensuring smooth overall operation.

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

The price of a Clay Shaftless Screw Conveyor varies depending on the material, specifications, length, and configuration. Small carbon steel models, with a diameter of approximately 200 mm and a length of 2 to 3 meters, cost around $800 to $1300, suitable for small brick factories or pilot projects. Medium-sized carbon steel models, with a diameter of 300 to 400 mm and a length of 5 to 10 meters, generally cost between $2000 and $4100, a popular choice for many building material factories. Stainless steel models, with a diameter of over 300 mm and a length exceeding 5 meters, typically cost between $3000 and $6500, suitable for applications requiring corrosion resistance. Larger, customized equipment, such as double-helix structures exceeding 30 meters in length, can cost between $90,000 and $15,000, and is commonly found on large production lines. Adding features like frequency converters and wear-resistant liners will further increase the overall cost.

Clay Shaftless Screw Conveyors are commonly used in applications requiring the processing of highly viscous materials with high moisture content. In the building materials industry, clay is fed to mixers or molding equipment during brick and tile production. Ceramic factories also frequently use it to deliver raw materials to the brick-pressing process, resulting in more stable molding. In wastewater treatment plants, it can transport dehydrated, muddy materials. In waste treatment plants, it is used to transfer clay-containing kitchen waste or mixed waste, minimizing the risk of jamming. In the chemical industry, it can be used to transport clay catalysts or viscous slurries; its stainless steel construction can withstand acidic and alkaline environments. In mines, it is used to transport clay powder, and in agriculture, it can transfer the clay component in organic fertilizer raw materials. Paper mills and food processing plants also use this equipment to handle clay slurries or plant residues.

The Clay Shaftless Screw Conveyor features a centerless structure, resulting in greater stability when conveying highly viscous materials with high moisture content. Compared to traditional equipment, wet clay and flaky materials are less prone to tangling or piling up during operation, significantly reducing material blockage issues. The helical blades directly propel the material forward, ensuring smooth material flow and stable equipment operation. While initial purchase costs may vary depending on materials, dimensions, and configurations, daily maintenance is relatively simple, with fewer downtimes for repairs, making it more worry-free in the long run. For factories that frequently handle viscous, high-moisture materials, this type of conveying equipment is highly reliable in actual production.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.