Dried vegetable residue linear vibrating screen is a vibrating screening device specially used for screening fibrous and granular materials such as dried vegetable residue. It can also screen dehydrated vegetable residue. Its core function is to achieve grading, impurity removal and fine processing of dried vegetable residue through efficient vibration. It is mainly used in food processing, feed, pharmaceutical, chemical and other industries to improve screening efficiency, remove impurities or grade materials.

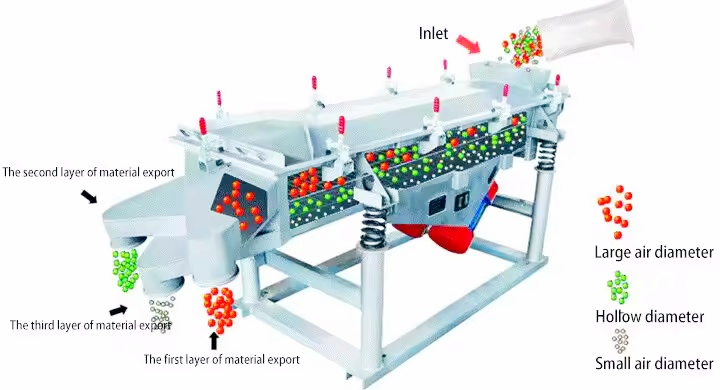

When the linear vibrating screen for dried vegetable residue is working, the vibration motor drives the screen body to produce linear vibration, so that the dried vegetable residue jumps forward on the screen and completes the screening at the same time. The fine dried vegetable residue material passes through the screen into the lower layer for collection, and the large particles or unscreened materials are discharged from the discharge port to achieve screening and grading.

1. The specific gravity of the material is easily dispersed

Dried vegetable residue is light in texture. During screening, it may fly due to airflow or excessive vibration, causing material loss and environmental pollution. Appropriately reduce the vibration intensity of the linear vibrating screen for dried vegetable residue so that the material can be evenly distributed.

2. Dried vegetable residue has a high moisture content and is easy to stick

If the dried vegetable residue is not completely dehydrated, it is easy to stick to the screen or the inside of the equipment during screening, affecting the screening efficiency. Adjust the inclination angle of the screen body of the linear vibrating screen for dried vegetable residue to make the material with a high moisture content easier to slide and avoid accumulation.

3. Uneven stratification of dried vegetable residue

Dried vegetable residue may have large differences in particle size. Light particles tend to float on the surface, while heavy particles sink to the bottom, resulting in poor grading effect. Dried vegetable residue linear vibrating screen uses dual vibration motors to run in opposite directions synchronously to ensure uniform vibration of the screen surface.

4. Dried vegetable residue is easy to entangle and clog the screen

Dried vegetable residue has strong fibrous properties and is easy to entangle on the screen and even clog the screen holes. Dried vegetable residue linear vibrating screen uses a stainless steel woven screen or a perforated plate screen to reduce the possibility of entanglement of fiber materials.

| Application scenario | Screening target | Recommended mesh size (mesh) | Remarks |

| Dehydrated vegetable processing | Remove un-crushed large pieces of vegetable leaves and rhizomes | 5-10 mesh | Suitable for primary screening |

| Seasoning processing | Refine dried vegetable residue and improve taste | 40-80 mesh | Suitable for making seasoning powder, soup, etc. |

| Feed processing | Grading different granular feeds | 10-40 mesh | Suitable for feed needs of different animals |

| Organic fertilizer production | Remove large impurities and refine fertilizer | 10-30 mesh | Suitable for powdered or granular organic fertilizer |

| Biomass fuel | Control particle size | 5-20 mesh | Ensure fuel uniformity and facilitate pressing and molding |

| Chinese medicine residue screening | Separate coarse and fine medicine residues to improve the quality of medicine powder | 40-100 mesh | Suitable for Chinese medicine powder, Chinese medicine tea, etc. |

| Sewage treatment | Filter vegetable residues to avoid clogging | 5-15 mesh | Suitable for solid-liquid separation |

Food processing industry-grading of dehydrated vegetable by-products

In the production of dehydrated vegetables (such as carrot slices, onion cubes, spinach leaves), dried vegetable residues will be mixed with different sizes of crushed and dust. Dried vegetable residue linear vibrating screen needs to grade these dried vegetable residues for different purposes.

Agricultural waste recycling-feed raw material screening

After drying, the dried vegetable residues (such as cabbage roots and potato skins) in the vegetable processing plant can be used as a source of crude fiber for animal feed. However, a dried vegetable residue linear vibrating screen is needed to remove impurities such as soil and stones, and grade them according to particle size to adapt to different livestock needs.

Organic fertilizer production-particle size standardization

Dried vegetable residue is rich in organic matter and is a high-quality raw material for making organic fertilizer. However, when the dried vegetable residue linear vibrating screen is used directly, the uneven particle size will affect the fermentation efficiency and the quality of the finished product, and it needs to be screened into uniform specifications.

Chinese herbal medicine processing-drug residue separation and recycling

During the drying process of Chinese herbal medicines (such as wolfberry and chrysanthemum), dried vegetable residue (such as stem and leaf debris) will be produced. These residues can be recycled for extracting active ingredients or making medicinal powder, but impurities must be removed and graded first.

Biomass energy-fuel particle pretreatment

Dried vegetable residue can be used as a raw material for biomass fuel (such as pellet fuel or briquette fuel), but the dried vegetable residue linear vibrating screen needs to screen out fine dust (affecting combustion efficiency) and oversized particles (affecting molding).

Dried vegetable residue linear vibrating screen can effectively solve the problems of particle size separation, impurity removal and grading encountered in the processing and resource utilization of dried vegetable residue through efficient screening capabilities. It is an important equipment for related industries to achieve automation, improve product quality and promote resource recycling.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.