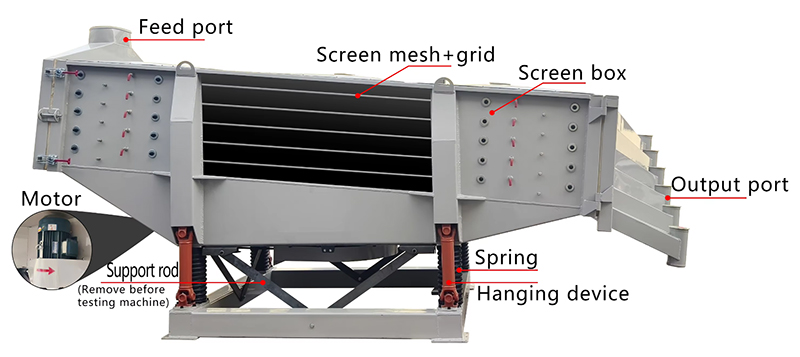

Gyratory vibrating system for sand (rotary vibrating screen) is a high-efficiency screening equipment designed for sand and gravel sorting. It adopts the principle of three-dimensional rotary vibration and can accurately classify various sand materials such as dry sand, wet sand, quartz sand, etc. The system consists of a vibrating motor, a screen box, a screen mesh, a spring shock absorber and a frame. The screen surface diameter is optional from 1 to 4 meters and the processing capacity is 5 to 150 tons/hour. The equipment adopts a fully enclosed structure design and is equipped with 304 stainless steel or polyurethane screen mesh to meet different industry standards such as food grade and chemical grade. Compared with traditional linear screens, the equipment occupies 30% less space and consumes 20% less energy. It is particularly suitable for high-precision and large-scale sand and gravel screening scenarios.

The unique rotation trajectory makes the material evenly distributed, the screening efficiency reaches more than 95%, and the processing capacity is 40% higher than that of the linear screen

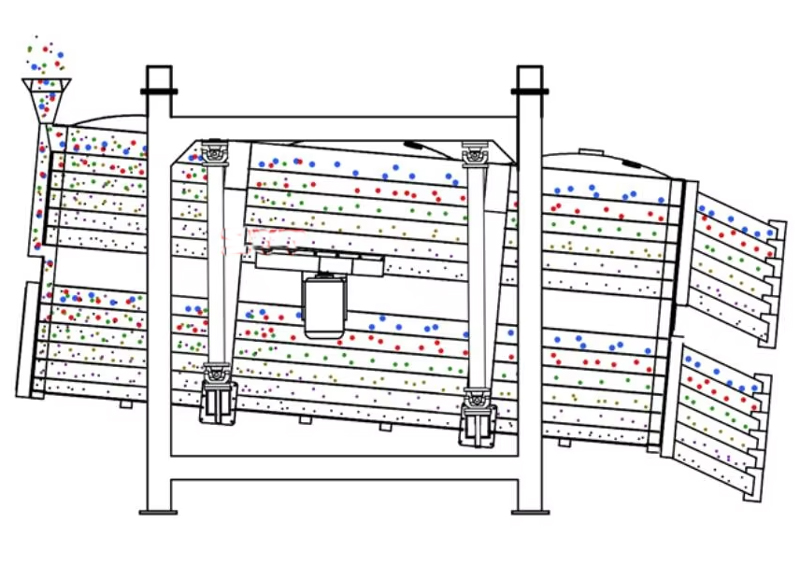

The three-dimensional vibration produces a self-cleaning effect, which completely solves the problem of wet sand blocking the screen. It can be configured with 2-5 layers of screens and produce 4-6 finished sands of different particle sizes at the same time.

The PLC system can be optionally equipped to monitor the amplitude, frequency and other parameters in real time to achieve unmanned operation. The fully sealed structure is equipped with rubber shock absorption, the working noise is <75 decibels, and the dust overflow is <5mg/m³.

The core of the equipment is driven by a dual vibration motor, and a composite force field is generated through a precisely calculated eccentric block to form a spatial spiral vibration trajectory. The material exhibits a triple motion of "throwing-diffusion-stratification" on the screen surface:

Throwing stage: the material is lifted into the air by the vertical acceleration to achieve particle dispersion

Diffusion stage: the horizontal rotation force makes the material spread evenly in a vortex shape

Stratification stage: fine particles pass through the screen under the action of gravity, and large particles spiral along the screen surface

The vibration parameters can be precisely adjusted (amplitude 2-8mm, frequency 700-1500rpm), and the screening mode can be quickly optimized for sand materials with different specific gravity and humidity. The specially designed elastic support system can absorb more than 90% of the vibration transmission to ensure stable operation of the equipment.

Machine sand classification (0-5mm fine sand/5-10mm medium sand/10-20mm coarse sand)

Concrete aggregate cleaning and screening

Dry-mix mortar production line

Industrial sand field

Quartz sand (40-70 mesh/70-100 mesh/100-200 mesh classification)

Regeneration and processing of resin sand for casting

Purification of silica sand for glass raw materials

Petroleum fracturing sand (20/40 mesh, 40/70 mesh precision classification)

Precise screening of 3D printing sand

River dredging sand dewatering and screening

Construction waste recycled aggregate sorting

Gyratory vibrating system for sand stands out as a high-performance screening solution, combining precision, durability, and energy efficiency. Unlike traditional linear or circular vibratory screens, this system utilizes a unique gyratory (elliptical) motion to optimize material flow, reduce clogging, and enhance screening accuracy.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.