Hose Conveyor For Vertical is a flexible conveyor designed for vertical or steep-angle material lifting. It enables material transfer between different floors. With its unique hose-like structure and helical propulsion principle, it overcomes the limitations of traditional vertical conveyors, such as large footprint and poor adaptability. The flexible hose is made of highly elastic and wear-resistant material, allowing for 360° bending and adjustment of the conveying direction to adapt to different site layouts. It can smoothly transport granular, powdery, and small lump materials, avoiding blockages and material damage.

The Hose Conveyor For Vertical features a fully enclosed structure design, effectively preventing dust leakage and moisture damage. We offer three drive options: electric power, motor, and diesel, easily handling diverse scenarios such as fixed workshop operations, outdoor mobile transfers, and sites without power supply. Customized configurations with two-phase, three-phase, and explosion-proof motors are also supported. We can recommend suitable solutions based on customer production conditions, site conditions, and material characteristics to meet the personalized conveying needs of different industries.

The Hose Conveyor For Vertical stands out in vertical conveying applications thanks to its unique design. Its small footprint allows for flexible adaptation to complex layouts, and it can handle a variety of materials, making it a top choice for efficiency improvement across numerous industries.

Small Footprint: The vertical hose conveyor's vertical design occupies only 1/3 the space of traditional equipment, making it particularly suitable for space-constrained factory layouts.

Enclosed, Dust-Free Conveying: The hose conveying system is completely enclosed, preventing material leakage and dust spillage, reducing material loss and environmental pollution.

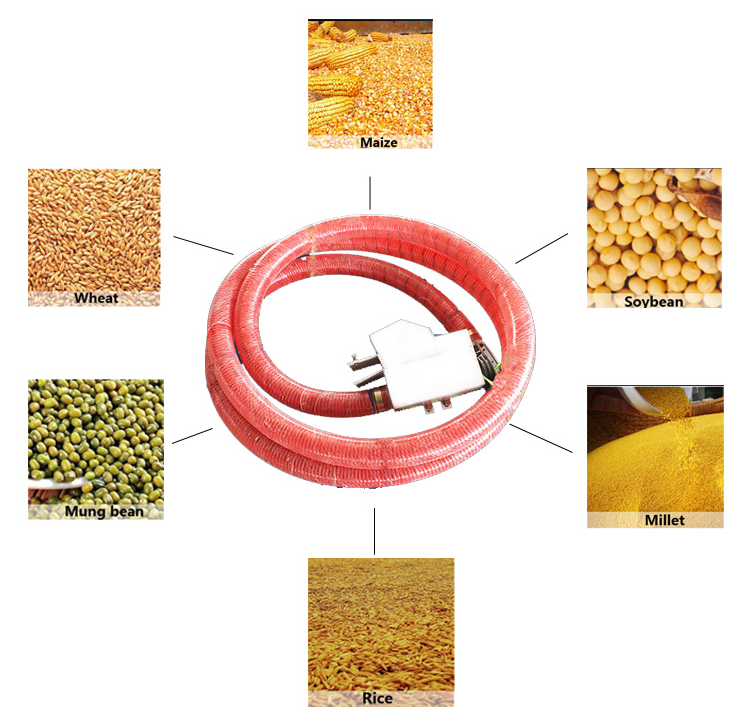

Wide Range of Applications: It can handle various material forms, including powders, granules, flakes, and pastes, with conveying capacities ranging from 1 cubic meter to 100 cubic meters per hour, meeting the needs of different production scales.

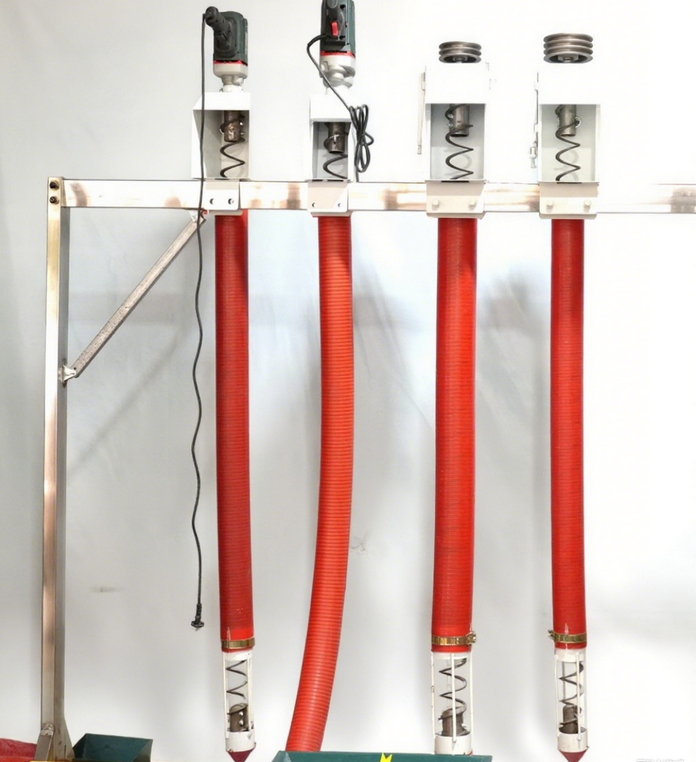

The Hose Conveyor For Vertical mainly consists of a drive unit, conveying hose, inlet and outlet ports, etc. These components work in precise coordination. The drive unit provides power, and the hose provides flexible conveying, achieving vertical material transport.

High-Strength Hose: The hose is made of high-strength, flexible, pressure-resistant, and anti-aging material.

Spiral Blades: Made of carbon steel or 304 stainless steel, precisely welded for strong propulsion, preventing material blockage, and suitable for vertical lifting of various materials such as granules and powders.

Drive Power Unit: Consists of a variable frequency motor, reducer, and coupling, installed at the top or bottom of the equipment, providing stable power to the spiral blades.

Feed Inlet: Equipped with an anti-clogging funnel, and can be fitted with a filter to intercept impurities, ensuring smooth material entry.

Discharge Inlet: Designed as an angled or straight outlet, and can be fitted with a sealing baffle to prevent material splashing, directly connecting to downstream equipment such as silos and production lines.

Control Auxiliary Unit: Composed of a control cabinet, overload protection device, and seals. The control cabinet integrates start/stop and speed adjustment functions for convenient operation; the overload protection device automatically stops the machine in case of material blockage.

When the Hose Conveyor For Vertical is working, material enters the hose through the feed inlet, and the drive unit generates power, creating a stable flow channel for the material within the hose. The flexible nature of the hose allows it to adapt to complex spatial layouts, easily bypassing obstacles and enabling continuous vertical, horizontal, and even curved path transport.

| Model No. |

Length (Meters) |

Pipe diameter |

Loading Capacity (t/h) |

Motor phase-power (kw) |

Installation | Structure | Conveying height |

| RLS100 | 4 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS120 | 4 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS-160 | 4meter | 160mm | 10—15 | Three phase-5KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5meter | |||||||

| 6meter | |||||||

| 8meter | |||||||

| (Customized) | |||||||

With its core advantages of flexible vertical lifting, fully enclosed dust prevention, and small footprint, the Hose Conveyor For Vertical is suitable for the vertical transfer needs of granular and powdery materials in various industries.

Food Processing: It can be used for the vertical lifting of materials such as grains, tea, nuts, and flour, enabling vertical transport of materials to silos or high floors, and is suitable for vertical docking of production lines from raw material warehouses to processing equipment.

Chemical Industry: It transports chemical powders, granular additives, pharmaceutical raw materials, etc. The fully enclosed design prevents materials from getting damp and evaporating, while avoiding the safety hazards of dust leakage. It can be flexibly arranged in narrow workshops and docked with packaging machines, mixers, and other equipment.

Agricultural and Feed Industry: Enables vertical transport of fertilizers, feed pellets, and seeds. The mobile frame, equipped with casters, allows for flexible docking with field transport vehicles and storage silos, meeting the bulk material lifting needs of farms and feed mills.

Building and Mining Industry: Conveys cement, mortar, and ore pellets. Wear-resistant hoses are impact-resistant and abrasion-resistant, and the sealed structure solves dust problems during vertical transport. Suitable for vertical feeding stages from raw material stockpiles to production equipment in cement plants and sand and gravel plants.

The vertical conveying height of the Hose Conveyor For Vertical is flexible. Ours is approximately 4 meters, but this needs to be considered in conjunction with the material characteristics. For conventional granular materials, due to their relatively poor flowability, the maximum vertical height can reach 6 meters with optimized equipment structure and reasonable power configuration, meeting the vertical lifting needs of most production scenarios. For powdery materials with better flowability, to ensure conveying stability and efficiency, the vertical height is recommended to be controlled within 4 meters. Actual selection should be based on parameters such as material particle size, density, and moisture content.

The Hose Conveyor For Vertical can transport materials with a certain moisture content, but the recommended moisture content is no more than 30%. When the material has a low moisture content, it is relatively dry, which increases friction and ensures smooth transport without feeding issues, enabling stable vertical transport. However, if the moisture content is too high, the material becomes too fluid, and the added moisture will cause feeding problems, making it impossible to complete the transport process.

Facing the complex challenges of vertical material transport, the Hose Conveyor For Vertical stands out with its unique advantages. It flexibly adapts to various working conditions, providing high-speed, stable transport performance and customized solutions for multiple industries.

Flour Vertical Transport: Flour processing plants need to achieve vertical transfer from the ground floor warehouse to the second-floor packaging line. The original equipment had problems with dust pollution and material residue. We customized a vertical flexible hose conveyor, using stainless steel spiral blades and PU hoses, with a lifting height of 3 meters and a fully enclosed structure to prevent dust leakage.

Vertical feeding of chemical powders: Requires a 4-meter vertical lift to connect with a reactor, and must meet salt spray corrosion resistance and explosion-proof requirements. Customized explosion-proof models are available, featuring fully enclosed piping and a nitrogen protection system to prevent material moisture absorption and evaporation. Variable frequency speed control enables precise feeding from 0.5-5 tons/hour.

Grain mobile transfer: Requires vertical transfer of grain from transport vehicles to storage silos in fields with limited space and frequent movement. Mobile vertical flexible hose conveyors are provided, equipped with casters and foldable supports. The hose length is 6 meters, the lifting height is 4 meters, and the hourly output is 3 tons to meet small-batch operation needs.

Dahan Machinery integrates independent R&D, customized production, and after-sales service. Products feature a fully enclosed structure design, with wear-resistant hoses and stainless steel spiral blades, suitable for conveying granular and powder materials in various industries. Our Hose Conveyor for Vertical supports customization of conveying height, pipe diameter, and drive method. We offer multiple drive types, including electric and diesel models, and configurations with two-phase, three-phase, and explosion-proof motors. We provide one-stop service, from solution design to factory commissioning. Our products are exported nationwide, and we guarantee delivery within a certain timeframe.

The Hose Conveyor for Vertical is a core piece of equipment for connecting different floors and achieving efficient material flow. While traditional vertical conveyors can meet basic needs, they have limitations in space adaptability, material compatibility, and environmental performance. The vertical flexible hose conveyor, with its unique hose structure and flexible conveying technology, breaks through the limitations of traditional equipment, becoming an ideal choice for vertical material conveying in various industries.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.