The mesh number of standard test sieve refers to the number of holes on the sieve per square inch. The higher the mesh number, the more holes the sieve has and the smaller the particle size. For example, 50 mesh means 50 holes per square inch, while 500 mesh means 500 holes per square inch.

There is a certain correspondence between mesh number and aperture. For example, when the sieve hole size is 4.75mm, the standard mesh number is 4 mesh; when the sieve hole size is 2.80mm, the standard mesh number is 7 mesh; when the sieve hole size is 0.300mm, the standard mesh number is 50 mesh.

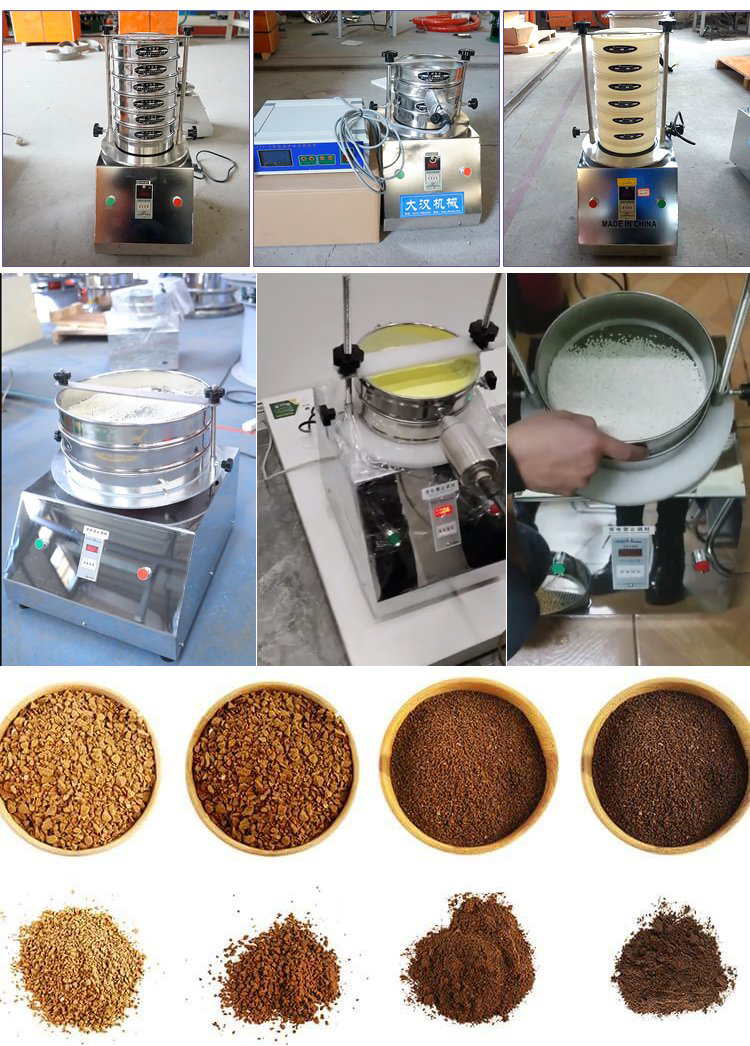

10 mesh: used for coarse powder screening, which can pass through the No. 1 sieve but is mixed with powder that can pass through the No. 3 sieve but not more than 20% of it.

24 mesh: used for coarse powder screening, can pass through the No. 2 sieve but mixed with powder that can pass through the No. 4 sieve not exceeding 40%.

50 mesh: used for medium powder screening, can pass through the No. 4 sieve but mixed with powder that can pass through the No. 5 sieve not exceeding 60%.

65 mesh: used for fine powder screening, can pass through the No. 5 sieve and contain powder that can pass through the No. 6 sieve not less than 95%.

80 mesh: used for fine powder screening, can pass through the No. 6 sieve and contain powder that can pass through the No. 7 sieve not less than 95%.

100 mesh: used for ultrafine powder screening, can pass through the No. 7 sieve and contain powder that can pass through the No. 8 sieve not less than 95%.

120 mesh: used for ultrafine powder screening, can pass through the No. 8 sieve and contain powder that can pass through the No. 9 sieve not less than 95%.

150 mesh: used for ultrafine powder screening.

200 mesh: used for ultrafine powder screening.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

As can be seen from the table above, different mesh numbers correspond to different aperture ranges. For example, the aperture range of a sieve with a mesh number of 20 is between 0.85 mm and 0.150 mm, while the aperture range of a sieve with a mesh number of 40 is 0.425 mm.

Through the standard mesh number and aperture comparison table, users can choose the appropriate sieve for screening operations according to their needs. If coarse screening is required, a sieve with a smaller mesh number and a larger aperture can be selected; if fine screening is required, a sieve with a larger mesh number and a smaller aperture can be selected.

The standard mesh number and aperture comparison table can also be used for the quality inspection of the sieve and the analysis of the screening results. In the quality inspection of the sieve, the sieve aperture can be measured and compared with the value in the comparison table to determine whether the manufacturing quality of the sieve meets the standard requirements. In the screening result analysis, the screening results can be accurately described and analyzed according to the standard mesh number of the selected sieve.

The standard mesh number and aperture comparison table is an important reference tool for screen selection and screening operations. Through the comparison table, users can easily select the appropriate screen to achieve accurate particle separation and screening. At the same time, it also provides a basis for the quality inspection of the screen and the analysis of the screening results, improving the accuracy and reliability of the screening work. These screens with different mesh numbers are widely used in the pharmaceutical, chemical, food and other industries to ensure that materials can be accurately separated according to the particle size requirements.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.