The auger feeder can be arranged horizontally, inclined or vertically. The motor drives the screw blade to transport the material in the trough from the feeding point to the discharging point. It is a widely used conveying equipment in the mining, feed, grain and oil, and construction industries. It will take you to understand the structure and principle of auger feeder.

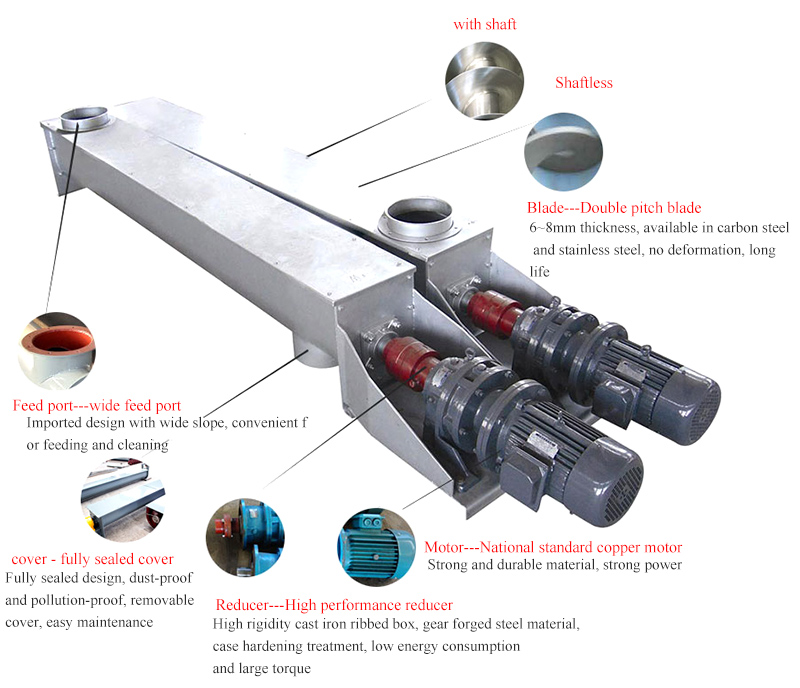

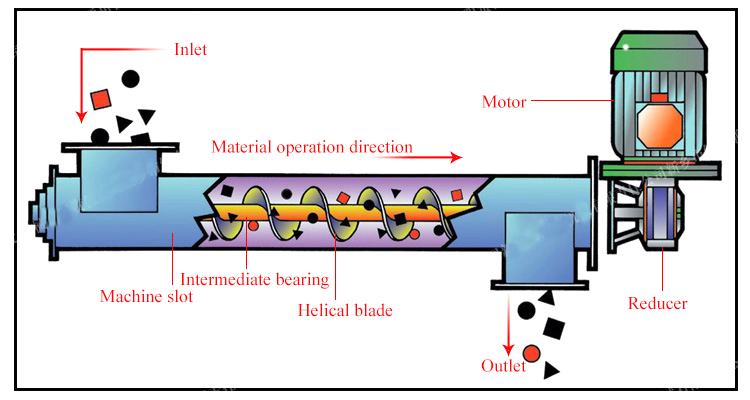

The auger feeder usually consists of a slot or tube containing a helical blade coiled on a shaft, driven at one or both ends, or a "shaftless helix", driven at only one end.

Feed trough: It is a U-shaped container in which the material is enclosed during the conveying process (picture). Slots are usually made of sheet steel and are available in standard lengths. If longer slots are required, connect a greater number of such units together.

Spiral shaft: It consists of a long, narrow sheet of steel of a certain thickness twisted into a helically wound, these standard threads are welded to the central shaft, or alternatively, the conveying element is suspended along the length of the slot with the help of a hanger .

Drive end and discharge end: Also known as the box, at the drive end, the shaft is connected to the bevel gear, the power is transmitted through the shaft to the helical blades, the shaft rotates around the shaft and remains close to the bottom of the tank. Feed is usually added through the feed port to provide a uniform flow of material. On the discharge end, an open chute or an open bottom chute is used to receive material.

When the power is turned on, the driver rotates the screw shaft through the gear, the screw element starts to rotate, the blade rotates around the shaft and is kept close to the bottom of the groove, the material is usually introduced from the feed port of the auger conveyor, and the material will fall into the gap between the screw blades. During the time, with the movement of the screw shaft, the material also moves forward along the path, and the material is discharged through the discharge port and enters the next program.

Auger feeders are used in many bulk handling industries. Auger conveyors in modern industry are usually used horizontally or slightly inclined as an efficient way to convey semi-solid materials, including feed, grain, flour, corn, soybeans, garbage, wood chips, aggregates, sludge, solid waste, etc. The hourly conveying volume is 1.4-458 cubic meters, and the conveying length can reach 70 meters.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.