U Type Screw Conveyor For Cement is a continuous conveying system designed for cement powder, cement clinker, and other cement materials. Leveraging the structural advantages of its U-shaped trough and sealed cover, it effectively solves the problems of dust pollution and material waste during cement conveying. Based on the core principle of screw propulsion, the drive system rotates wear-resistant blades, achieving smooth transfer of cement from the silo to the mixer, packaging machine, or transport vehicle. It adapts to different site layout requirements and is available in carbon steel or 304/316L stainless steel.

The U-Type Screw Conveyor for Cement supports horizontal and ≤20° inclined conveying. The maximum conveying length for a single unit can reach 30 meters, with pipe diameters ranging from 150-800mm. The hourly output can be precisely adjusted from 5-50 tons via a variable frequency speed control motor to meet different production capacity needs. The drive system can utilize a cycloidal pinwheel reducer and an explosion-proof motor, ensuring stable operation and low noise. It also features overload protection to prevent damage caused by cement clumping. Furthermore, we support non-standard customization, allowing us to tailor suitable conveying equipment to your specific needs and site conditions.

To suit customers' needs for conveying cement powder or cement slurry, we offer two main types of U Type Screw Conveyor For Cement shafted and shaftless. Each type differs in performance and applicable scenarios.

Shafted U-type screw conveyor: This type uses a screw shaft as its core support, with blades welded to the shaft. The shaft rotation drives the blades to push the cement. It features a stable structure, high conveying efficiency, and is suitable for the conventional transfer of non-adhesive materials such as dry cement powder and cement clinker. It is widely used for short-distance conveying from cement plant mills to storage silos.

Shaftless U-type screw conveyor: This type features a shaftless design, with blades directly connected to the drive unit. The trough is equipped with wear-resistant liners. It has strong anti-winding and anti-clogging capabilities, and its conveying capacity can reach 1.5 times that of shafted models. It is suitable for cement materials containing a small amount of moisture and prone to caking, and also allows for multi-point feeding and unloading.

The U Type Screw Conveyor For Cement is designed for cement materials that are powdery, prone to dust generation, and slightly corrosive. Its U-shaped structure and sealed design make it the preferred equipment for cement transfer applications.

Sealed and Dust-Proof: Utilizing a fully enclosed structure with a U-shaped trough and a removable sealing cover, and a wear-resistant sealing strip between the cover and the trough, it effectively prevents cement dust leakage, resulting in dust levels far below industry standards.

Long Service Life: The trough is made of thickened carbon steel or 304 stainless steel, with polished or wear-resistant lining on the inner wall to reduce cement adhesion and friction wear. The spiral blades are made of wear-resistant alloy material with reinforced edges, capable of withstanding long-term cement erosion.

Wide Adaptability: It can adapt to materials in different states, such as dry cement powder and cement clinker, meeting the varying production capacity requirements of cement plants and mixing stations.

High space utilization: The U-shaped design is simple, occupying only 1/3 the area of a traditional belt conveyor. It can be flexibly embedded in narrow spaces such as under silos and in workshop corners, requiring no complex infrastructure and adapting to various site layouts.

Strong connectivity: It can seamlessly connect with cement silos, discharge valves, screw scales, mixing equipment, etc., to form an automated conveying line, improving overall production efficiency.

Customization support: It supports customization of trough length, pipe diameter, material, and drive configuration according to conveying distance, capacity, and installation angle to meet personalized transfer needs.

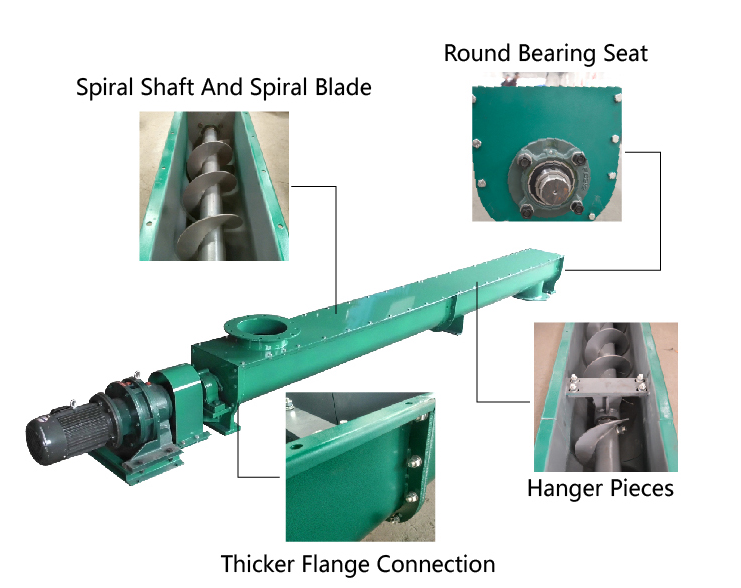

TheU Type Screw Conveyor For Cement mainly consists of core components such as the drive unit, U-shaped trough, screw shaft and blades, hanger bearing system, inlet and outlet ports, sealing device, and base.

Drive unit: The drive unit is the power source of the U-type screw conveyor, typically composed of an electric motor, reducer, and coupling.

U-shaped trough: This is the main structure of the conveyor. The bottom of the trough has a semi-circular arc design, which helps form a continuous flow layer of cement during transportation, preventing material accumulation and blockage.

Screw shaft and blades: The screw shaft is the core component of the conveyor, usually made of 45# steel or stainless steel, which has high strength and wear resistance. The screw blades are formed by cold rolling and fixed to the screw shaft. The thickness and pitch of the blades can be adjusted according to the different characteristics of the conveyed material.

Hanger bearing: Used to support the screw shaft and ensure its stability during rotation. The hanger bearing adopts a sliding bearing structure, and the bearing bush is made of copper-based graphite low-oil lubricating material, which has good wear resistance and self-lubricating properties.

Inlet: Usually designed at one end of the conveyor for easy loading of materials such as cement.

Outlet: Located at the other end or side of the conveyor, used to discharge materials.

When the U Type Screw Conveyor For Cement is in operation, the drive unit rotates the screw shaft, and the screw blades fixed on the shaft rotate accordingly. Material enters the U-shaped trough from the feed inlet and is propelled forward in a spiral motion along the trough by the thrust generated by the rotating blades. The variable pitch design ensures more uniform and efficient material conveying, while the fully enclosed structure and sealing devices prevent dust leakage. Finally, the cement is continuously and stably conveyed to the discharge outlet, completing the entire conveying process.

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

We provide customized U Type Screw Conveyor For Cement solutions for customers in various industries, including cement plants, mixing plants, and building material warehouses. We accurately recommend suitable models based on customer operating conditions, conveying parameters, and environmental requirements, helping various industries achieve stable cement transfer.

Large Cement Plant: Cement needs to be conveyed from the bottom of the silo to a packaging machine 15 meters away. The original equipment suffered from severe dust leakage and frequent material blockages, affecting efficiency. A carbon steel U-shaped screw conveyor with a shaft and a 500mm diameter is selected, equipped with a variable frequency motor and a sealed cover with rubber sealing strips for enhanced dust prevention. After commissioning, the dust concentration dropped to 2.5mg/m³, and there was no material blockage.

Concrete mixing plant: Cement needs to be conveyed from an outdoor silo at a 20° angle to an 8-meter-high mixer, and it needs to be adapted to intermittent feeding requirements. A customized U-shaped screw conveyor is adopted, with a double-end drive design to ensure stable power. Optimized blade pitch prevents cement from slipping. After commissioning, the feeding response speed is increased by 35%, completely solving the problems of limited space and material moisture.

Small building materials plant: A multi-point transfer of cement from storage tanks to batching machines and packaging machines is required, demanding equipment with a small footprint and easy maintenance. A small 300mm diameter U-shaped screw conveyor is introduced. The U-shaped trough is equipped with a removable cover for easy daily cleaning of residual cement, and the external head and tail bearing seats reduce maintenance difficulty. The equipment occupies only 1.5㎡ of space and allows for flexible switching of conveying paths.

The material selection for a U Type Screw Conveyor For Cement should consider cement properties, operating conditions, and budget: Carbon steel is preferred for general applications; 304/316L stainless steel is recommended for conveying cement containing moisture, operating in humid/acidic/alkaline environments, or where material cleanliness is required; for special scenarios, custom polyurethane or wear-resistant alloy liners can be used to further enhance wear resistance and achieve a balance between practicality and cost.

A U Type Screw Conveyor For Cement can convey cement slurry with a water content of up to 30%. When the water content exceeds 30%, viscous lumps are prone to form, which may clog the conveying channel or adhere to the screw blades, affecting the normal operation of the equipment. Therefore, it is necessary to strictly control the water content of the cement slurry and regularly clean residual materials inside the equipment to ensure conveying efficiency and service life.

Dahan Machinery'sU Type Screw Conveyor For Cement starts at $500, with pricing tailored to different customer needs, offering excellent value. The basic model is made of carbon steel, suitable for conventional dry cement transfer, meeting the basic conveying needs of small and medium-sized building material plants and mixing plants. Upgraded models are available with 304/316L stainless steel, capable of handling humid and slightly corrosive conditions, ensuring long-term stable operation. Price differences mainly stem from material selection, customized conveying parameters, and other personalized requirements that will affect the final quote. We offer free selection consultation and solution design, with no hidden fees. Standard models are readily available for direct shipping, and customized products are quoted precisely based on specific needs. With transparent pricing and superior quality, we provide cost-effective cement transfer solutions for businesses of all sizes.

TheU Type Screw Conveyor For Cement, with its compact structure, excellent sealing, and stable conveying capabilities, is widely used in all stages of cement production. It can transport powdery cement slurry with a water content of up to 30%, effectively preventing dust leakage and reducing maintenance costs. It is an indispensable conveying tool in the cement industry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.