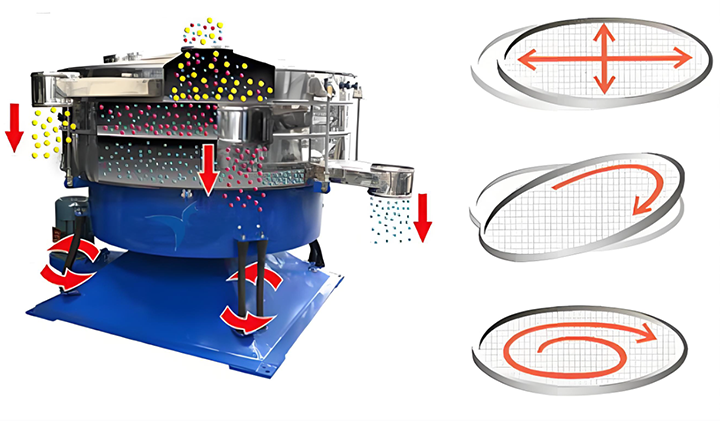

Urea granule vibrating screen sorts granules by size, removing dust, broken particles, and oversized particles to ensure the finished product meets particle size standards. It also removes impurities, improving product purity and preparing the material for storage, transportation, and application. It uses an eccentric shaft to drive a low-frequency oscillation, causing the material to move across the screen. Qualified particles fall off, while unqualified particles are discharged along the screen surface.

The equipment is constructed of 304 or 316L stainless steel, making it resistant to slight corrosion from urea and preventing material adhesion. The screen can be made of polyurethane or stainless steel mesh and is equipped with a ball or brush cleaning device to address moisture absorption and clogging issues. The inner wall of the machine has a corrosion-resistant coating, and the motor is explosion-proof and corrosion-resistant, making it suitable for humid and dusty environments. The screen mesh size and number of layers are adjustable, allowing for three-stage grading of dust, qualified particles, and oversized particles in a single pass. Production capacity ranges from 1 to 50 tons per hour.

The urea granule vibrating screen provides a gentle screening process, suitable for easily breakable urea granules. Urea granules fall evenly onto the screen surface from the feed inlet. An eccentric mechanism drives the screen to slowly oscillate, causing the material to move forward along the screen surface in a parabolic trajectory. Dust and broken particles fall into the collection trough first. Qualified granules pass through a second screen to become the finished product, while larger particles are discharged at the end and returned for re-granulation. Its low-frequency, low-amplitude motion allows the urea granules to slide and tumble on the screen surface, rather than violently jumping, resulting in less collision and friction. The curved screen surface ensures more even material distribution, preventing accumulation and crushing, and the breakage rate can be controlled below 1%.

| Screening Grade | Aperture/Particle Size Range (mm) | Product Category | Typical Application |

| ≥4.0 mm | >4.0 | Coarse Granules | Large-grained chemical fertilizers, reducing dust, suitable for mechanical spreading |

| 2.8-4.0 mm | 2.8-4.0 | Qualified Granules | Conventional fertilizer sales products, suitable for most agricultural needs |

| 2.0-2.8 mm | 2.0-2.8 | Medium Granules | Used for special crops or mixed fertilizers |

| 1.5-2.0 mm | 1.5-2.0 | Fine Granules | Adjusting ratio or used as raw material for compound fertilizers |

| <1.5 mm | <1.5 | Powder/Returned Material | Recycled to the factory for re-granulation or used as powder |

The Urea granule vibrating screen offers the following advantages. Urea is prone to absorbing moisture, clumping, and sticking to screens. This equipment features an anti-clogging device that continuously taps the screen to ensure smooth passage of urea granules without clogging. Urea granules are relatively brittle; the oscillating screening action allows the granules to slide and tumble on the screen surface, reducing breakage and minimizing dust and nitrogen loss. While urea is weakly alkaline and can corrode equipment over time, the stainless steel body with an anti-corrosion coating ensures longevity and minimal maintenance. The fully enclosed design prevents dust from being inhaled by operators and avoids granule clumping due to moisture absorption, which would affect screening. Compared to traditional screening machines, it offers precise grading while preserving the integrity of urea granules.

| Model | Diameter (mm) | Screen Area (m²) | Feed Size (mm) | Screening Size (mm) | Processing Capacity (t/h) | Amplitude (mm) | Motor Power (kW) |

| YBS800 | 800 | 0.29 | ≤25 | 0.073-3 | 6-10 | 5-8 | 0.75 |

| YBS1000 | 1000 | 0.71 | 8-15 | 1.5 | |||

| YBS1200 | 1200 | 1.11 | 15-30 | 2.2 | |||

| YBS1600 | 1600 | 1.83 | 25-40 | 3 | |||

| YBS2000 | 2000 | 2.62 | 30-50 | 4 | |||

| YBS2500 | 2500 | 4.61 | 40-60 | 5.5 |

The Urea Granule Vibrating Screen provides gentle yet precise screening, making it suitable for various applications. For example, in large urea plants, it can be connected to the granulation, cooling, and packaging production lines, operating continuously, 24 hours a day. Blending fertilizer plants can use it to screen urea of different sizes, ensuring accurate formulations. Agricultural supply warehouses or logistics centers can use it for secondary screening of incoming urea, removing broken particles and dust from transportation, making storage more stable. It is also suitable for agricultural cooperatives, small fertilizer plants for small-batch urea grading, or research institutions for testing urea granule performance.

The urea granule vibrating screen uses low-frequency oscillation to slowly screen the granules. With its corrosion-resistant and anti-clogging design, it is less prone to clogging and breakage. It solves the problems of urea's moisture absorption, clumping, and brittleness, while producing cleaner finished granules, maintaining stable output, and extending the equipment's lifespan. Whether for large-scale continuous production or small-batch screening, this equipment helps control granule quality and production efficiency. Its screening action is smooth and gentle, allowing the particles to slide and tumble on the screen surface, resulting in less breakage and less dust. It is a very practical machine for grading urea particles in fertilizer plants.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.