The vibrating hopper unloader is a discharging device designed to solve the problem of difficult discharge of powder, granules and materials with poor fluidity. Its function is to generate adjustable mechanical vibration at the bottom of the hopper to loosen and flow the materials, thereby achieving a continuous, uniform and stable unloading process. It is especially suitable for materials with poor fluidity, easy to agglomerate or irregular particles. Depending on the hopper volume, material density and vibration parameters, the typical processing capacity of the equipment can range from 300 kg to more than 10 tons per hour.

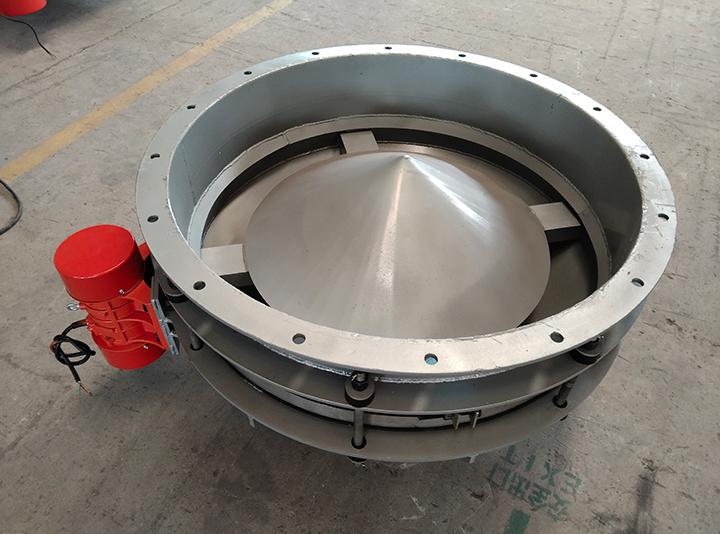

The core working principle of the vibrating hopper unloader is to use the vibration motor installed at the bottom of the hopper to generate periodic vibration, so that the materials near the hopper wall or the discharge port are in a loose and fluidized state, thereby overcoming the blockage problem caused by humidity, static electricity, viscosity or irregular particles. The equipment is mainly composed of a hopper body, a vibration exciter (usually a double eccentric vibration motor), a bracket, a connecting flange and a control system. Some models are also equipped with a flexible discharge sleeve, a buffer ring or a flow regulator to adapt to different application environments.

When the equipment is powered on, the vibration motor starts and drives the hopper to vibrate. The materials are disturbed by high-frequency and low-amplitude mechanical fluctuations and rearranged to form a "slip zone" or "flow surface" to achieve uniform and continuous material discharge. The vibration amplitude and frequency can be finely adjusted by the controller to adapt to different material types and process requirements.

The Vibrating Hopper Unloader is suitable for various types of bulk materials, especially for powders, particles, moisture-absorbing and bridging materials, mixed materials or irregular particles. For fine powder materials, such as calcium carbonate, starch or talcum powder, vibration can effectively prevent the material from adhering to the material wall or clogging; in the treatment of granular materials, such as plastic particles or sand, the equipment can maintain a stable flow to avoid material bridging and stoppage; and for materials that are easy to absorb moisture or have irregular particle shapes, vibration can break up the agglomeration area to ensure that the material falls smoothly at the discharge port, thereby ensuring the continuity and uniformity of material discharge.

The equipment can be used with hoppers of different sizes, and the adapted silo capacity ranges from tens of liters to several tons. The vibration frequency is usually 960-1500 times/minute, the amplitude range is 0.5-3mm, and the processing capacity can achieve a discharge efficiency of several hundred kilograms to more than ten tons per hour according to the hopper volume and material density.

Ensure continuous unloading: Vibrate to disturb the material, effectively solve the problems of poor unloading, wall hanging, and material collapse, and is suitable for materials of various forms;

Compact structure and strong adaptability: It can be connected with various storage silos, hoppers, mixing tanks, etc., with small footprint and convenient installation and maintenance;

Adjustable vibration parameters: The amplitude and frequency can be freely adjusted according to the characteristics of different materials to ensure stable flow rate; As a stable unloading device, the vibrating hopper unloader is widely used in various material conveying and unloading systems with its simple structure, reliable performance, wide range of materials and high degree of automation. Through reasonable selection and parameter adjustment, Vibrating Hopper Unloader can not only significantly improve unloading efficiency and reduce human intervention, but also optimize the continuity and stability of the entire process. Whether in conventional production lines or automated control systems, this equipment can achieve accurate and efficient material control and is a key component of modern bulk material handling systems.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.