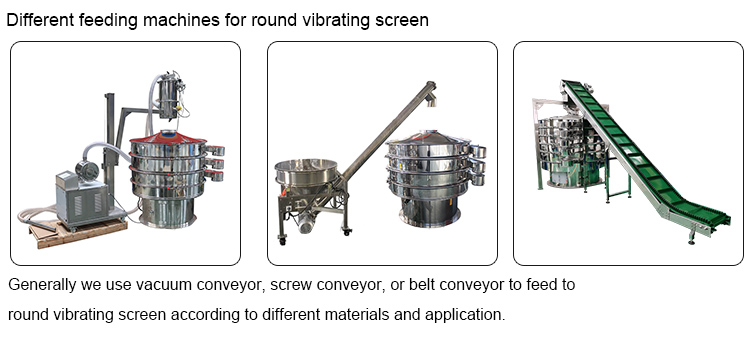

Food vibrating screens are specifically used in the food processing industry as an effective way to protect ingredients and final products from contamination and caking, and are typically made from a single-layer sheet containing a screen that is used to screen out liquids and powders Oversize, agglomerates, and foreign objects, the motor attached to the screen uses an unbalanced force to create vibrations that move material through the screen.

In order to meet the advanced hygienic and hygienic parameters of the food industry, our special vibrating screen is made of high-quality materials that meet food specifications, SS304 or SS316 material, mirror polished, internal and external surface finish 0.1-0.2RA, easier to clean, ensure no material deposition, can be Prevent contamination and provide dust-free operation. Its closed construction prevents leaks and helps keep the screened material free from outside interference.

| Type | Mesh | Output |

| Granticle food rotation sieve | 10μ-60μ(0.25mm-1.7mm) | 3t / h-5t / h |

| Tea-Leaves:10mm/8mm/6mm/4mm/2mm etc.. | ||

| Powder type food rotary vibration sieve | 20μ-100μ(0.15mm-0.85mm) | About 2,000 kg / h |

| Fluid food rotation sieve | 40μ-200μ(0.38mm-0.075mm) | —— |

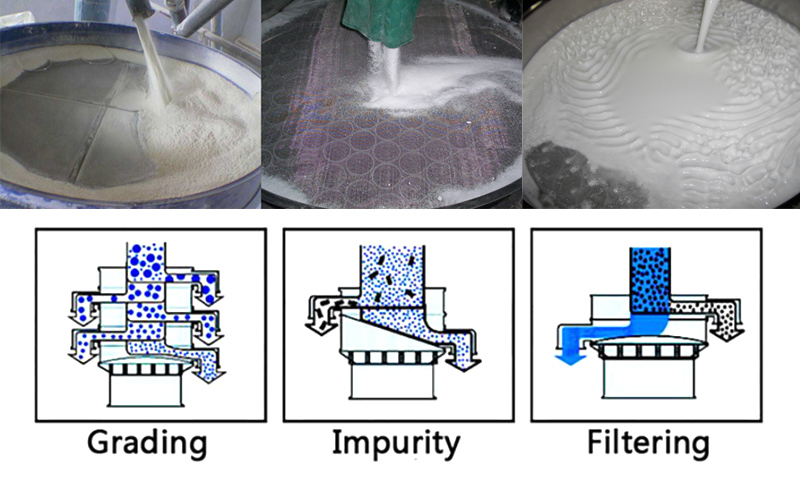

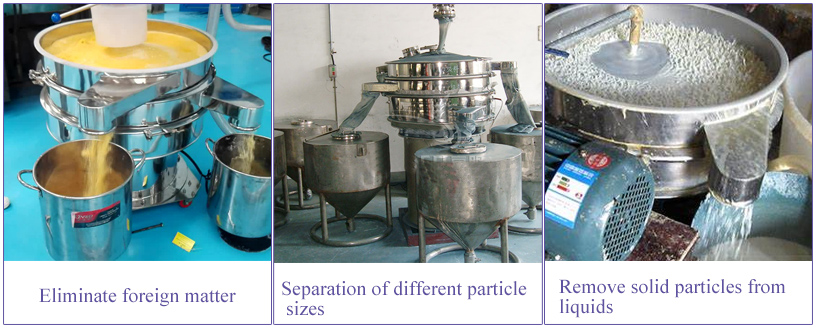

1. Impurity removal: The purpose of removing impurities can be achieved by using a single-layer rotary vibrating screen for food, such as sieving out broken tea residues, pebbles in sesame seeds, unbroken beans in soy milk, etc.;

2. Grading: sieve the materials by fineness grade, such as flour with different mesh numbers and different uses, tea leaves with different qualities, etc.

1. SS304 or 316L stainless steel material is mirror polished, which makes cleaning the machine very easy and helps to audit material deposits.

2. The fully enclosed structure can effectively prevent external dust from entering and cause pollution to food materials, and can effectively prevent waste of resources caused by material leakage, and can also avoid workshop pollution caused by material leakage.

3. It can screen 500 mesh or 0.028mm materials, and is also equipped with a screen surface cleaning device such as a bouncing ball, which reduces the occurrence of material blocking and further improves the screening accuracy.

4. The screen can reach up to 5 layers, and can screen up to 6 kinds of materials with different particle sizes for the homogenization of particles.

5. Casters can be installed for free movement in the factory when needed.

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

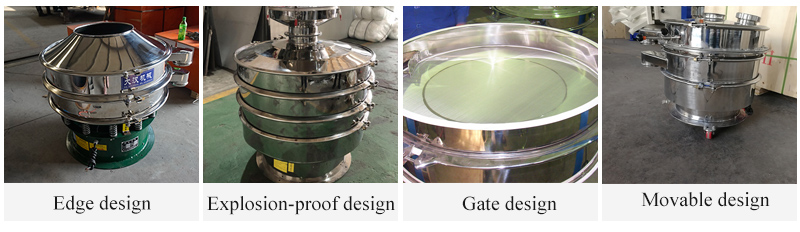

1. Edge design: by raising the feeding port, it can prevent liquid materials such as juice from splashing;

2. Explosion-proof design: use an explosion-proof motor with good sealing to avoid the danger of static electricity and flying powder of extremely fine powder materials such as flour;

3. Gate design: the discharge port can be closed through the gate, which prolongs the screening time of food in the vibrating screen, making the screening more fine and uniform;

4. Movable design: The screening machine is equipped with a universal wheel device to cooperate with the production and screening of food.

| Application examples of food vibrating screen in the food industry | |||||

| Raw Material | Proportion | Mesh | Model | Method |

Throughput (kg/h or t/h) |

| wheat starch | 1 | 250 | DH-1200-1S | Wet | 3200 t |

| corn starch | 0.6 | 40 | DH-1000-1S | Dry | 1600㎏ |

| flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| yeast liquid | 0.5 | 32 | DH-1000-1S | Wet | 8000 t |

| rice flour | 0.5 0.8 | 100 | DH-1000-1S | Dry | 300 ㎏ |

| soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 t |

| salt | 1.2 | 30/80 | DH-1500-1S | Dry | 5000㎏ |

| pollen | 0.4 | 12 | DH-1500-1S | Dry | 100㎏ |

| Tofu | 1 | 120 | DH-1000-1S | Wet | 2500 t |

| sweetener | 0.7 | 40/80 | DH-800-2S | Dry | 320㎏ |

| granulated sugar | 1.2 | 12 | DH-1500-1S | Dry | 8000㎏ |

| Pineapple juice | 1 | 100 | DH-1000-1S | Wet | 3000㎏ |

| skim milk powder | 0.57-0.7 | 24 | DH-1200-1S | Dry | 3000㎏ |

| rice bran | 0.5 | 16 | DH-800-1S | Dry | 500㎏ |

| powdered sugar | 0.5-0.8 | 100 | DH-800-1S | Dry | 200㎏ |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.