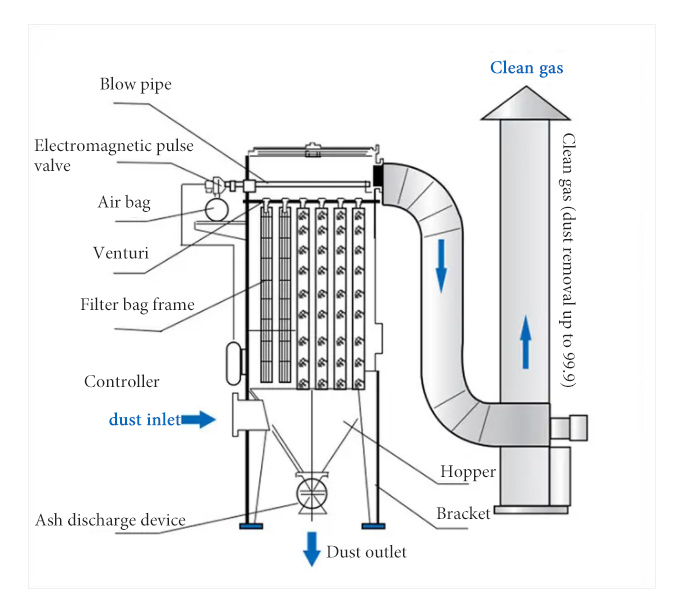

Through the principle of bag filtration, solid particles and dust in the gas are efficiently removed.

![]()

![]()

![]()

Price:$769.00-$2,499.00/Set

Consult now and enjoy a 10% discount

Motor power:7.5kw

Air volume of fan:11000m³/h

Fan speed:30-45m/sec

Inlet size:ø6''*5pcs(On demand)

Dust bag:ø630*2pcs + ø175*24pcs

Overall size:2400*1070*3350mm

Packing size:2400*1070*850mm

Application: It is widely used in various industrial fields, such as cement production, metallurgy, chemical industry, food processing, etc.

Commitment:

Bag dust collector is a dry dust filter device that uses a large capacity filter bag and a powerful blower to remove dust and particles in the blasting chamber, so it is also called bag filter dust collector, suitable for capturing fine, dry, non-fibrous dust . The filter bag is made of woven filter cloth or non-woven felt, and uses the filtering effect of fiber fabric to filter the dust-laden gas. When the dust-laden gas enters the bag dust collector, the dust with large particles and heavy specific gravity will be affected by gravity. It settles down and falls into the ash hopper. When the gas containing finer dust passes through the filter material, the dust is blocked, so that the gas can be purified.

Bag dust collector has the advantages of high dust removal efficiency, stable operation, small footprint, and wide application range. It is widely used in mining, metallurgy, chemical industry, building materials and other industrial fields. Under different working conditions, bag dust collectors can select different filter bag materials and structures according to gas properties and dust characteristics to ensure the best dust removal effect.

1. According to the shape of the filter bag, it is divided into: flat bag (trapezoid and flat) and round bag (cylindrical).

2. According to the way of air inlet and outlet, it is divided into: lower air inlet and upper air outlet, upper air inlet and lower air outlet and direct current type (limited to plate flat bags).

3. According to the filter method of the bag, it is divided into: external filter type and internal filter type.

Fibers for filter media include cotton fiber, wool fiber, synthetic fiber and glass fiber, etc. The filter media woven from different fibers have different properties. The commonly used filter materials are 208 or 901 polyester flannel, the operating temperature is generally not more than 120 ° C, the glass fiber filter bag treated with silicon resin is generally not more than 250 ° C, and the cotton wool fabric is generally suitable for non-corrosive; Dusty gas below 80-90℃.

When the dust-laden gas enters the ash hopper from the air inlet pipe at the lower part of the precipitator and enters the ash hopper through the deflector, due to the collision of the deflector and the reduction of the gas velocity, the coarse dust will fall into the ash hopper, and the rest of the fine particle dust will follow the gas. Entering the filter bag room, due to the inertia, diffusion, blocking, hooking, static electricity and other effects of the filter material fibers and fabrics, the dust is retained in the filter bag, and the purified gas escapes the bag and is discharged through the exhaust pipe.

High dust removal efficiency

Generally above 99%, the dust concentration in the outlet gas of the dust collector is within tens of mg/m3, and it has a high classification efficiency for fine dust with sub-micron particle size.

Large processing capacity

The small one is only a few m3 per minute, and the large one can reach tens of thousands of m3 per minute. It can be used for flue gas dust removal in industrial furnaces and kilns to reduce the emission of air pollutants.

Low cost

Under the premise of ensuring the same high dust removal efficiency, the cost is lower than that of the electrostatic precipitator.

High temperature resistance

When using glass fiber, polytetrafluoroethylene, P84 and other high temperature resistant filter materials, it can operate under high temperature conditions above 200 °C.

Stable operation

It is not sensitive to the characteristics of dust and is not affected by dust and resistance.

Space saving

Using high-speed filtering long filter cloth, compared with the existing models, the space is saved by more than 20%.

Bag dust collector is composed of dust collector hopper, air inlet duct, filter room (middle and lower box), clean room, filter bag and (bag cage bone), manual air inlet valve, pneumatic butterfly valve, pulse cleaning mechanism, etc.

| Specification for Bag Dust Collector Machine | |||

| Model | MF9075 | Motor power | 7.5kw |

| Air volume of fan | 11000m³/h | Fan speed | 30-45m/sec |

| Inlet size | ø6''*5pcs(On demand) | Dust bag | ø630*2pcs + ø175*24pcs |

| Overall size | 2400*1070*3350mm | Packing size | 2400*1070*850mm |

1. Machinery manufacturing: mainly in the foundry industry, commonly used in the casting process of mold shells using natural quartz sand, clay, graphite powder and talc powder as raw materials. The main types of work that come into contact with dust include sand mixing, sand mixing, molding, and casting boxing, sand cleaning, and metal grinding. The foundry industry is also one of the main industries where pneumoconiosis occurs.

2. Mining of mines: It is the most important industry that produces dust, and it is also the industry with the most serious harm to pneumoconiosis. The types of jobs most exposed to dust are rock drillers, transport workers, etc.

3. Smelting industry: The crushing, sintering and beneficiation of ores in metal smelting can generate a large amount of dust, and smelting workers are widely distributed in steel smelting and other metal smelting industries.

4. Building materials: refractory materials, glass and cement manufacturing industries, mining, processing, crushing and sieving of stone materials, as well as the mixing, molding, furnace firing, and enamel industries of raw materials in ceramic production, mainly in contact with silica dust and Silicate dust.

5. Road construction industry: including tunnel excavation and road paving in railway and highway construction. hydropower industry. Tunnel excavation and underground power station construction in the water conservancy and power industry.

6. Stone processing industry: such as the processing and production of stone tablets and stone mills.

7. Wood processing: The manufacture of wooden furniture will generate a large amount of wood dust.

8. Coal mining industry: In coal mines, there are mainly tunnelers, coal miners, porters, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.