Belt conveyor with a hopper is a specific type of material handling equipment that combines a belt conveyor system with a hopper at the feeding end. This arrangement allows for the controlled loading and transfer of bulk materials from the hopper onto the conveyor belt.The hopper serves as a container or reservoir for the bulk material, providing a storage space from which the material can be loaded onto the conveyor belt.

Belt conveyors with hoppers are widely used in industries such as mining, agriculture, construction, manufacturing, and recycling. They are suitable for handling a variety of bulk materials, including grains, ores, aggregates, chemicals, and other commodities. These systems offer advantages such as efficient material transportation, high capacity, and the ability to handle various material sizes and weights.

Belt conveyors with hoppers are suitable for a variety of industries and material handling scenarios. Here are some common applications:

Mining and Quarrying: Transporting bulk materials such as coal, ore, gravel or aggregates from hoppers to processing or storage areas.

Agriculture: For handling bulk materials such as grain, seeds, fertilizers and animal feed. Hoppers allow controlled loading and transfer of these materials to conveyor belts for efficient transportation.

Construction: Used on construction sites for handling materials such as sand, gravel, concrete and construction waste. Hoppers facilitate easy loading of these materials onto conveyor belts for efficient movement around the site.

Manufacturing and Production: Manufacturing and production industries often use belt conveyors with hoppers to transport raw materials, components or finished products within their facilities. Hoppers allow for controlled loading, ensuring a consistent and regulated flow of material on the belt.

Recycling and Waste Management: Used to transport recyclable materials such as paper, plastic, glass and metal from hoppers to sorting, processing or storage areas.

Food Processing: For handling bulk food such as grains, fruits, vegetables and meat. Hoppers help control loading onto the conveyor belt, ensuring gentle, hygienic transport.

Packaging and logistics: Moving products from one processing or packaging station to another. Hoppers efficiently load goods onto conveyor belts, simplifying packaging and logistics.

Aggregate and Construction Material Handling: Typically used in aggregate plants, construction material handling yards and concrete batching plants. They help transfer bulk materials such as sand, gravel and crushed stone from hoppers to storage bins, mixers or trucks.

The working principle of belt conveyor with hopper includes the following steps:

Material loading: Load the bulk material to be conveyed into the hopper at the feeding end of the conveying system. Hoppers may have adjustable flow gates or feeders to regulate material flow and ensure a controlled loading process.

Conveyor Start: Once the hopper is loaded, the conveyor system starts. This is usually done by turning on the motor that drives the conveyor belt. The motor provides the power needed to move the belt and transport the material.

Belt motion: When the motor is turned on, it drives the pulleys around which the conveyor belt loops. The belt begins to move, forming a continuous loop that spans the length of the conveyor system. Belts are usually made of durable materials such as rubber, PVC or steel and are designed to withstand the weight and wear of the material being conveyed.

Material Conveying: As the belt moves, bulk material in the hopper begins to flow onto the conveyor belt due to gravity or a controlled discharge mechanism. The material is transported along the conveyor belt from the feed end to the discharge end.

Unloading or transfer: After reaching the discharge end of the conveyor, the material can be unloaded directly or transferred to another conveyor or processing equipment. The exact method of discharge depends on the application and desired material handling.

Versatility: Belt conveyors with hoppers are versatile and can handle a variety of bulk materials such as grains, ores, aggregates, chemicals, etc. They can be accommodated in a variety of material sizes, shapes and weights to suit a variety of applications.

Controlled Material Loading: The hopper provides a controlled and regulated loading point for bulk material on the conveyor belt. This ensures a consistent and controlled flow of material on the belt, preventing spillage, uneven distribution or overloading.

Efficient material transportation: the combination of hopper and belt conveyor can efficiently transport bulk materials from the hopper to the desired destination. The conveyor belt moves material smoothly and continuously, minimizing downtime and maximizing throughput.

Space optimization The hopper is integrated with the belt conveyor to realize compact and space-saving material handling. Materials can be stored in hoppers, reducing the need for additional storage equipment and optimizing the overall layout of the material handling system.

Design flexibility The belt conveyor with hopper can be customized to meet specific requirements. The design of the hopper can be customized according to the characteristics of the material being conveyed, ensuring smooth and efficient loading. Belt conveyors can also be configured to suit the available space and desired conveying path.

Improved safety: These systems increase the safety of material handling operations. Hopper designs can include features such as gates, feeders, and level sensors to help control material flow and prevent overloading. Additionally, safety features such as covers, guards and emergency stops are available to ensure operator safety.

Reduce material waste and spillage: The controlled loading provided by the hopper minimizes material waste and spillage during transfer. Not only does this reduce material loss, it also helps maintain a clean, safe work environment.

Cost-effectiveness: Belt conveyors with hoppers provide cost-effectiveness in material handling operations. They provide efficient and reliable transportation, reduce labor requirements and minimize the need for manual intervention. The streamlined transfer process also improves overall productivity and operational efficiency.

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

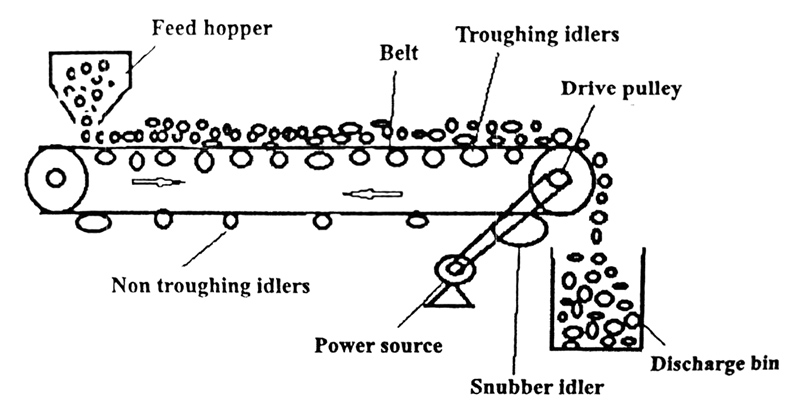

The structure of a belt conveyor with a hopper typically consists of the following components:

Hopper: The hopper is a container or reservoir located at the feeding end of the conveyor. It serves as a storage space for the bulk material before it is loaded onto the conveyor belt. The hopper is designed to facilitate controlled loading and may include features such as adjustable flow gates, feeders, or level sensors.

Conveyor Belt: The conveyor belt is the primary component responsible for transporting the material. It is a continuous loop made of durable materials such as rubber, PVC, or steel. The belt is supported by rollers or idlers and is driven by a motorized pulley or a separate drive unit. The belt is designed to withstand the weight and abrasion of the conveyed material.

Frame Structure: The frame structure provides the support and stability for the conveyor system. It is typically made of steel or aluminum and consists of beams or channels that form the framework to which the conveyor components are mounted. The frame structure is designed to withstand the weight of the material being conveyed and the forces generated by the belt tension.

Drive System: The drive system provides the power to move the conveyor belt. It typically includes a motor, a gearbox or a motorized pulley, and associated components such as couplings and bearings. The drive system is responsible for starting, stopping, and controlling the speed of the conveyor belt.

Pulleys and Rollers: The pulleys and rollers support and guide the conveyor belt. The head pulley is located at the discharge end of the conveyor and is responsible for driving the belt. The tail pulley is located at the feeding end and provides support for the return side of the belt. Intermediate rollers or idlers are placed along the conveyor length to support the belt and maintain proper tension.

Skirting and Sealing: Skirting and sealing components are used to contain the material on the conveyor belt and prevent spillage or dust emissions. Skirting is installed on the sides of the belt to create a seal between the belt and the hopper or surrounding structure. Sealing elements such as rubber seals or brushes may be used to minimize material leakage at transfer points.

Safety Features: Safety features such as covers, guards, emergency stops, and safety switches are incorporated into the structure to ensure safe operation and protect personnel from hazards.

A mining company uses a belt conveyor with hopper to transport ore from the mining site to the processing plant. This equipment can effectively capture and transport large pieces of ore through the design of a hopper, improving transportation efficiency and stability. The reliability and durability of the belt conveyor ensure continuous production operations and reduce downtime and maintenance costs. The mining company has achieved efficient ore transportation and improved production efficiency through a belt conveyor with a hopper.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.