Cocoa separation machine is a piece of equipment used in the cocoa processing industry to separate cocoa solids from cocoa butter, cocoa separation is an important step in chocolate production as it helps to remove unwanted impurities and provides quality and consistency in the final product , by vibrating the mixture on a sieve to separate the cocoa solids from the cocoa butter, which are separated and collected for further processing.

Cocoa separation machines are commonly used in the cocoa processing industry to separate cocoa powder and other cocoa solids from cocoa butter. Here are some examples of how the cocoa separation machine applies to cocoa separation:

1. Pre-screening: It can be used for pre-screening of cocoa powder to remove any large particles or impurities that may be present. This helps ensure a consistent quality and texture of cocoa powder, which is important in achieving the desired flavor and appearance of chocolate products.

2. Separation of cocoa solids: it can be used to separate cocoa solids and cocoa butter. The cocoa powder is placed on a sieve which vibrates to separate the cocoa solids from the cocoa butter. The separated cocoa solids can then be further processed into cocoa powder or used in other applications.

3. Classification: The cocoa powder can be classified according to the particle size distribution. This helps ensure uniformity and consistency in the final product, which is important to achieve the desired texture and properties of chocolate products.

4. Dedusting: A sieve can be used for dedusting cocoa powder to remove any dust or other impurities that may be present. This is important to maintain product quality and prevent contamination in cocoa processing plants.

There are several types of separation machines that can be used in the coco industry for various applications, including:

Vibro Sifter

It is used to sieve and separate cocoa powder and other cocoa solids from cocoa butter. The rotating motion of the sieve helps to prevent the material from sticking to the sieve, ensuring a more efficient and accurate sieving process. The sieving can reach 500 mesh , The processing capacity can reach 100-3300 kg per hour.

Ultrasonic Vibrating Screen

Used for screening and grading of cocoa powder and other cocoa solids in the cocoa industry, the ultrasonic deblinding system helps to improve the screening efficiency and accuracy of fine powder, effectively prevents the sieve hole from clogging, and allows accurate separation to 20m (#635 mesh). To ensure a more efficient and accurate screening process.

Linear Vibrating Screen

Can be used to separate whole cocoa beans from broken or damaged cocoa beans, as well as other impurities such as stones, twigs and debris, can separate different cocoa beans into 7 different sizes, the linear movement of the screen ensures more efficiency and accuracy the separation process.

Cocoa beans of different sizes are sieved through the cocoa separation machine. Through different meshes, different cocoa beans are sieved out. Materials smaller than the sieve holes pass through the sieve holes and fall to the lower layer. After continuous jumping It flows out through the discharge port to complete the grading operation of the material, and multi-layer screens can be stacked to screen multiple grades of mesh. For example, the first layer is used to remove the large impurities in the cocoa beans, and the cocoa beans fall through the sieve to the second layer of sieve, and the cocoa beans larger than the second layer of sieve can continue to flow along the vibrating force of the sieve. The discharge port runs, and the required grade is screened out, and the impurity powder smaller than the mesh size of the screen can be discharged in the third layer. Circulating this process removes unusable parts such as debris, twigs or impurities such as broken cocoa beans, ensuring that only the best quality beans remain.

Cocoa separation machine for cocoa powder

Cocoa separation machine for coffee beans

1. Improve efficiency: Cocoa solids can be separated from cocoa butter faster and more accurately, thus helping to improve the efficiency of the cocoa processing process. This results in higher throughput and productivity, which can ultimately increase profits for cocoa processing companies.

2. Improved quality: Helps improve the quality and consistency of cocoa products by ensuring that only high-quality cocoa solids are used for further processing. This results in a higher quality and more consistent end product, which is important in achieving the desired flavor, texture and appearance of chocolate products.

3. Clean and hygienic: 304 stainless steel material, clean and hygienic, not easy to hang powder, not easy to pollute raw materials.

Reduced waste: Cocoa solids can be more precisely separated from cocoa butter, helping to reduce waste during cocoa processing. This results in a higher yield of usable cocoa solids, which can ultimately reduce costs and increase profits for cocoa processing companies.

4. Flexibility: There are many types and configurations of cocoa separators, which can make the cocoa processing process more flexible. This means that cocoa processing companies can choose the type of cocoa separator that best suits their specific needs and requirements.

5. Automation: Many cocoa separators are fully automatic, which improves the efficiency and precision of the cocoa processing process. This reduces the need for manual labor and increases the accuracy and consistency of the separation process.

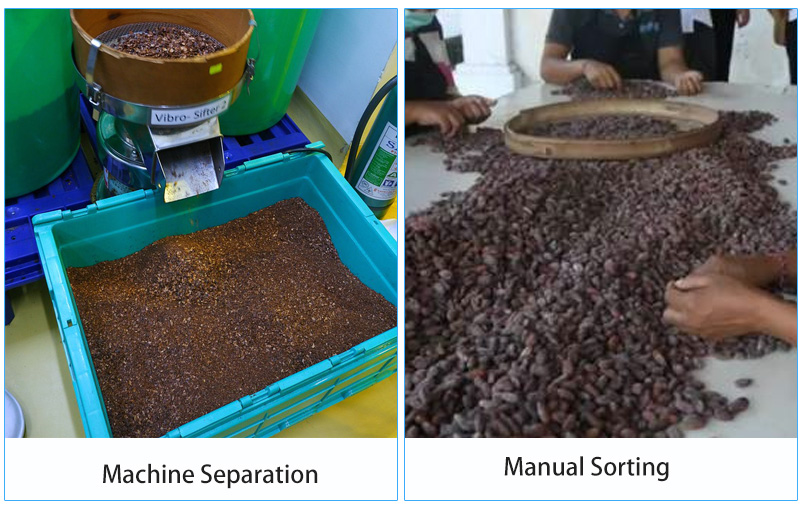

Manual screening is labor-intensive, and the operator is directly exposed to dust, which is very harmful to respiratory organs and skin. The cocoa separation machine can greatly reduce physical labor and reduce the chance of contact with dust. Equipped with an automatic feeding machine, it saves time, effort, and Manual, and can be well sealed, the operator will get rid of dust hazards.

| Compare Items | Cocoa Separation Machine | Manual Sorting |

| Automation | Is automated and uses various mechanisms such as hydraulic presses, screw presses, centrifuges, vibrating screens or combination machines to separate the cocoa solids from the cocoa butter. | It is done by hand, requiring a labor-intensive process of visual inspection and sorting of the cocoa beans. |

| Precision | Provides greater precision in the separation process, resulting in a more consistent and higher quality product. | Manual sorting of cocoa is prone to human error and can result in inconsistent separation of cocoa solids from cocoa butter, resulting in lower product quality. |

| Fineness | Much faster than manual cocoa sorting, which increases productivity and increases the efficiency of the cocoa processing process. | Manually sorting cocoa powder is a slow process that requires a lot of time and labor. |

| Consistency | Consistent and uniform separation of cocoa solids and cocoa butter results in a more consistent and higher quality product. | Manual sorting of cocoa can result in inconsistent separation and reduced product quality. |

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Q: How do you separate cocoa beans?

A: Safely removes any debris or impurities such as twigs, stones or other foreign matter, and also selects and grades cocoa beans according to their size and quality.

Q: How is cocoa powder separated from cocoa butter?

A: By using a customized layered sieve and 3D motion to screen the product, the product smaller than the size of the sieve passes through the sieve smoothly, and the larger particles remain on the sieve surface, it can be used to filter cocoa solids and cocoa butter to remove any residual impurities.

Q: How much does the cocoa separation machine cost?

A: The price range is $800.00-$4,500.00/Set, depending on the material you choose (carbon steel, stainless steel), the number of layers (1-5 layers, the higher the separation level, the more layers), and different configurations, the price will vary.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.