Used to uniformly or quantitatively supply products from storage bins or other storage equipment to receiving equipment

![]()

![]()

![]()

Price:$500.00-$4,700.00/Set

Consult now and enjoy a 10% discount

Feed particle size: 50-500mm

Output: 5-1400t/h

Vibration frequency: 3000 times/min

Amplitude: 1.5mm、1.75mm

Speed: 6-18m/min

Type: closed type, open type, hanging type, wide groove type

Material: carbon steel, stainless steel

Application: Especially suitable for processing materials that are sensitive to impact or require precise feed control, suitable for various industries such as mining, metallurgy, chemical industry, pharmaceuticals, and food processing

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

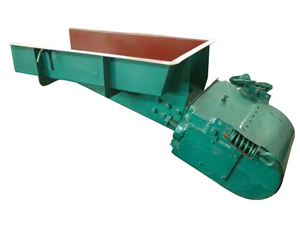

Electromagnetic vibrating feeder is driven by electromagnetic vibration exciter, which can uniformly, continuously and quantitatively send powder and granular materials to the receiving device, especially suitable for automatic batching, quantitative packaging, automatic production process, and high feeding accuracy.

Electromagnetic vibrating feeders are often divided into two types: open type and closed type. According to the installation method, it can be divided into hanging type and desktop type. During normal feeding, it can be installed with a downward tilt of 10°. For materials with high viscosity or high water content or fine powder, it can be installed with a downward tilt of 5°.

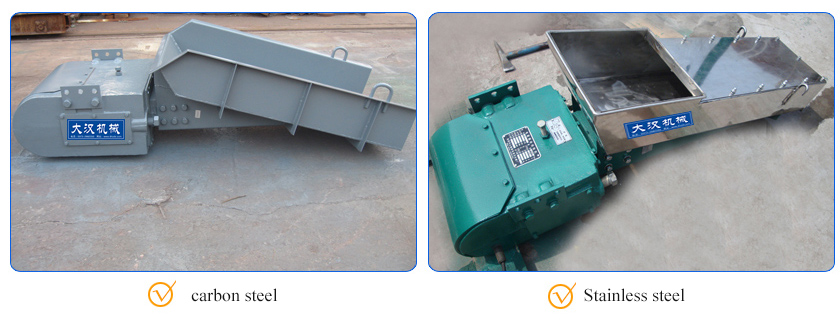

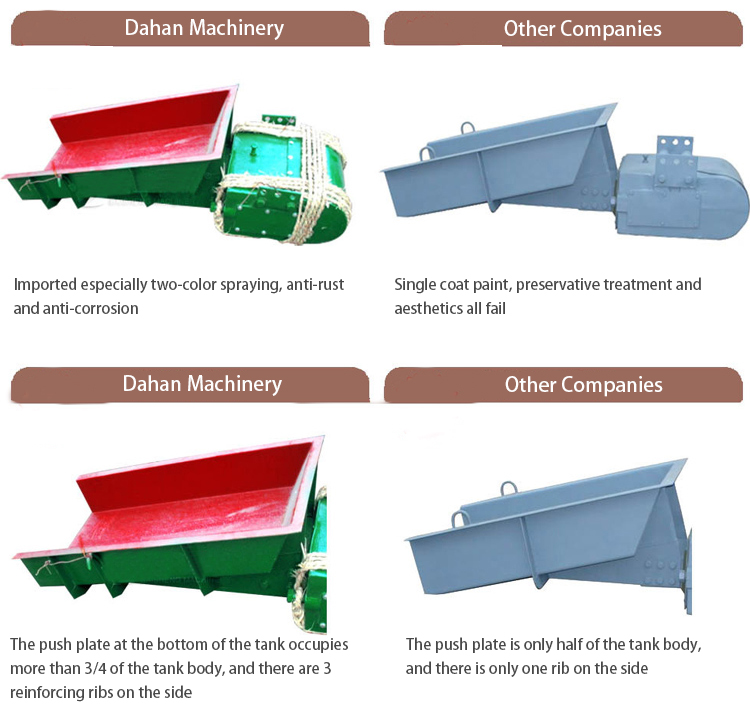

1. According to the material:

Carbon steel: Q235 carbon steel trough is used, which is suitable for customers with low hygiene requirements, and the price is cheap.

Stainless steel: It is made of SUS304 stainless steel trough, which is resistant to corrosion, high temperature, not easy to rust, and can avoid the pollution of raw materials.

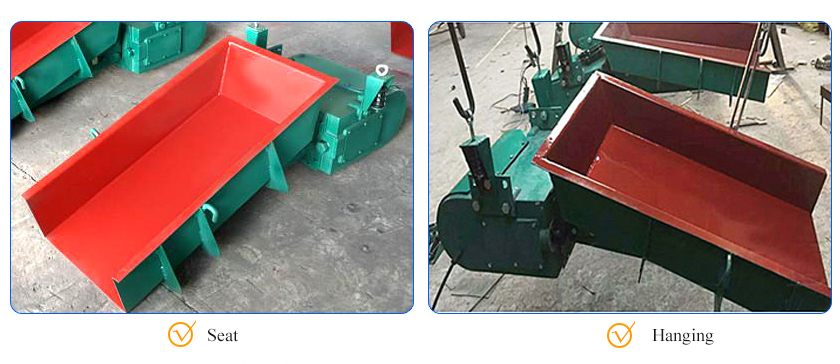

2. According to the structure, it can be divided into:

Open type: It is a common structure. Suitable for material feeding without special requirements.

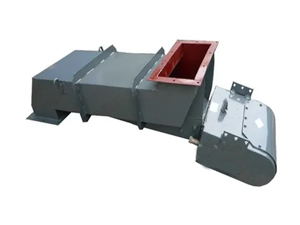

Enclosed type: Enclosed electromagnetic vibrating feeder adopts closed body design, which can prevent dust pollution. It is suitable for feeding materials with fragile particles, large dust and easy volatilization.

3. According to the installation method:

Seat type: Under normal conditions, it can be installed with a downward tilt of 10°. For materials with high viscosity or high water content or fine powder, it can be installed with a downward tilt of 15°.

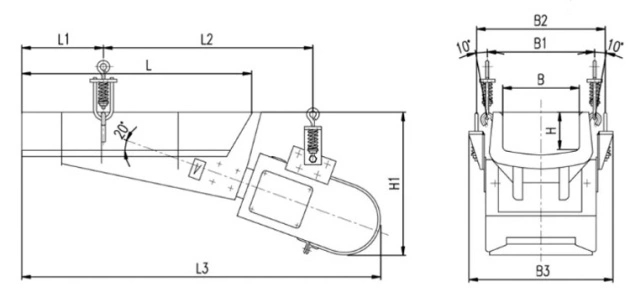

Hanging type: Hanging type installation, the body performs periodic linear reciprocating motion along the groove direction to achieve uniform and quantitative feeding. After installation, the feeder should have a 20mm swimming gap, and the horizontal direction should be horizontal. The suspension device adopts flexible connection .

| Type | Productivity calculation capacity (t/m³) |

Use | |

| basic type |  |

1.6 | Material feeding without special requirements |

| Closed type |  |

1.6 | Install and use when the configuration space is not enough, others are the same as the basic type |

| Hanging type |  |

1.6 | Typically used for feeding heavy or bulky materials |

| Round tube type |  |

1 | The entire conveying process is carried out in a sealed circulation pipeline, which is suitable for conveying dusty and volatile materials |

Electromagnetic vibrating feeders are widely used in various industries that require controlled and precise feeding. Some common industries that use electromagnetic feeders are:

Mining and Quarrying: Used to feed bulk materials such as ore, rock and aggregate into crushers, screens or conveyors. Precise, controlled feeding ensures efficient and even processing of the material.

Chemical and pharmaceutical: for precise dosing and feeding of powdery or granular materials. They are often integrated into production processes where precise measurement and delivery of ingredients or additives is crucial.

Food and Beverage: For controlling the feeding of ingredients, additives or bulk materials. They are commonly used in processes such as mixing, blending, packaging and delivery of food products.

Recycling and Waste Management: Used to feed materials such as shredded paper, plastic, glass or metal into processing equipment. Controlled feed facilitates efficient sorting, separation and recycling of various materials.

Construction and Construction Materials: Used to feed aggregate, sand, cement or other bulk materials into batching plants, mixers or concrete plants. Accurate and consistent feeding ensures the desired composition and quality of concrete or building materials.

Ceramics and Glass: Used to control the feeding of raw materials such as powders or granules. Precise dosing helps maintain the desired composition and consistency of the mixture.

Plastics and Rubber: Used to feed granular, granulated or powdered materials into molding machines, extruders or mixers. Controlled feed ensures uniformity and consistency in the production process.

The working principle of the electromagnetic vibrating feeder is to use the electromagnetic coil to generate vibration, so that the material moves along the tray or trough. Here's a step-by-step explanation of how it works:

Magnetic field generation: When current passes through the electromagnetic coil, an alternating magnetic field is generated. The magnetic field causes the coil and attached tray to vibrate.

Vibration: The alternating magnetic field causes the coil and tray to vibrate up and down or back and forth, depending on the design. These vibrations are transmitted to the material loaded onto the pallet.

Material Movement: The vibratory motion of the pallet moves the material forward in a controlled manner along the pallet or chute. Material is transported or fed to the discharge end of the feeder.

By adjusting the amplitude and frequency of the vibration, the electromagnetic vibrating feeder can effectively regulate the flow rate and prevent clogging or uneven material distribution.

Precise and controlled dosing

The amplitude and frequency of vibration can be adjusted to achieve the desired flow rate and ensure accurate metering or feeding. This level of control is especially important in industries where precise material handling is critical, such as pharmaceutical, chemical and food processing.

Handle materials gently

Controlled vibrations ensure smooth transport of materials without damage or degradation. This is especially beneficial for handling materials that are prone to breakage, segregation or degradation during transport.

Versatility in Material Handling

A wide variety of materials can be handled, including powders, granules and solid blocks. They are suitable for both fine and coarse materials and are therefore suitable for a wide variety of industrial applications. Feeders can be adapted to different material sizes, shapes and characteristics, allowing flexibility in the material handling process.

Reliability and Durability

They are constructed of strong materials such as stainless steel or mild steel to withstand heavy-duty use and harsh environments. Electromagnetic drive units are known for their long life and minimal maintenance requirements, ensuring high reliability and durability.

Energy efficient

Electromagnetic drive units efficiently convert electrical energy into mechanical vibrations. The ability to control vibration and regulate flow helps to optimize energy consumption and reduce material waste, resulting in cost savings during production.

Easy to integrate and automate

They can be synchronized with other equipment such as crushers, screens or conveyors for seamless material flow. Feeders can also be equipped with various control options such as timers, sensors or programmable logic controllers (PLC) for automated operation and process optimization.

| Model | Productivity (t/h) | Feed particle size (mm) |

Double amplitude(mm) | Voltage (V) |

Current (A) | Power (KW) |

Matching control box | ||

| horizontal | —10° | Working current | Indicates current | ||||||

| GZ1 | 5 | 7 | 50 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 |

| GZ2 | 10 | 14 | 50 | 3 | 2.3 | 0.15 | |||

| GZ3 | 25 | 35 | 75 | 4.58 | 3.8 | 0.2 | |||

| GZ4 | 50 | 70 | 100 | 8.4 | 7 | 0.45 | XKZ-20G2 | ||

| GZ5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | |||

| GZ6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.2 | XKZ-20G3 |

| GZ7 | 250 | 350 | 250 | 24.6 | 20 | 3 | |||

| GZ8 | 400 | 560 | 300 | 39.4 | 32 | 4 | |||

| GZ9 | 600 | 840 | 350 | 47.6 | 38.6 | 5.5 | XKZ-200G3 | ||

| GZ10 | 750 | 1050 | 500 | 39.4*2 | 32*2 | 4*2 | XKZS-200G3 | ||

| GZ11 | 1000 | 1400 | 500 | 47.6*2 | 38.6*2 | 5.5*2 | |||

Electromagnetic vibrating feeder is mainly composed of tank body, electromagnetic vibration exciter and vibration damper.

| Model | Weight(kg) | Dimensions | |||||||

| L1

|

L2

|

L3

|

L4

|

H1

|

H2

|

B1

|

B2

|

||

| GZ1 | 77 | 910 | 600 | 209 | 100 | 360 | 200 | 280 | |

| GZ2 | 151 | 1175 | 660 | 120 | 450 | 300 | 388 | ||

| GZ3 | 233 | 1325 | 900 | 311 | 790 | 150 | 520 | 400 | 496 |

| GZ4 | 460 | 1615 | 1100 | 413 | 965 | 200 | 645 | 500 | 620 |

| GZ5 | 668 | 1815 | 1200 | 463 | 1050 | 250 | 765 | 700 | 850 |

| GZ6 | 1271 | 2410 | 1600 | 400 | 1470 | 250 | 1030 | 900 | 720 |

| GZ7 | 1920 | 2800 | 1800 | 650 | 1465 | 250 | 1130 | 1100 | 840 |

| GZ8 | 3040 | 3302 | 2200 | 750 | 1800 | 300 | 1343 | 1300 | 1000 |

| GZ9 | 3750 | 3515 | 2400 | 800 | 2000 | 300 | 1440 | 1500 | 1010 |

Electromagnetic vibrating feeders are versatile in handling various materials such as bulk materials, granular materials, powders, and even sticky or abrasive materials. They are suitable for feeding materials like coal, ore, limestone, gypsum, cement, chemicals, food ingredients, and aggregates. The electromagnetic vibration allows for precise control over the flow rate, making it ideal for applications requiring accurate dosing or feeding.

Electromagnetic vibrating feeder is one of the equipment on the batching production line. It has good quality, simple structure, long life, low energy consumption and high efficiency. It can feed the equipment more uniformly and continuously during operation. The conventional shell is cast iron The material can be customized (carbon steel, stainless steel), wear-resistant, high temperature resistant, corrosion resistant, long life, reasonable selection and design according to working conditions, no material jam, uniform feeding, and customized according to size.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.