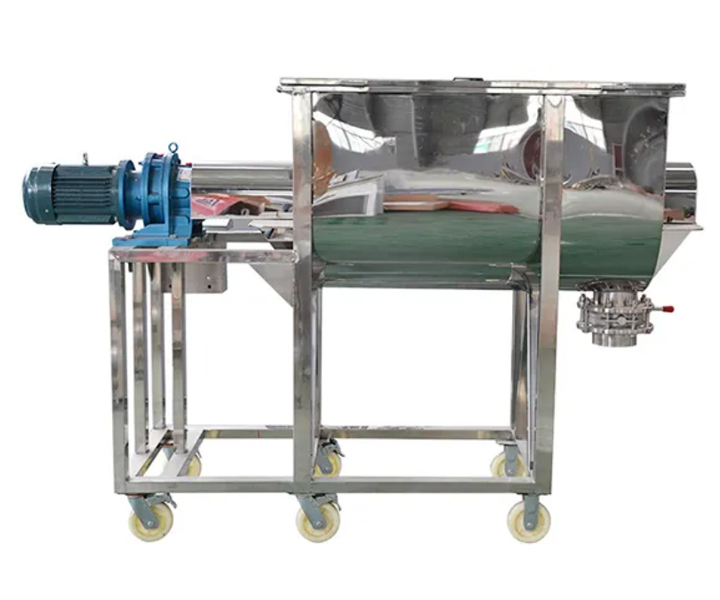

Mechanical equipment used for mixing feed, mainly composed of U-shaped container, spiral ribbon stirring blades and transmission parts.

![]()

![]()

![]()

Price:$300.00-$3,500.00/Set

Consult now and enjoy a 10% discount

0.5 tons/hour to 20,000 liters/batch

One-time mixing:100-6000 (kg)

Mixing time:8-20 (min)

Mixing speed:15-60(r/min)

Motor power 3-75(kw)

Commitment:

The feed ribbon mixer is a piece of equipment used for feed processing and is mainly used to mix different types of feed raw materials. It includes a belt conveyor and a mixer. The feed raw materials are sent into the mixer through the ribbon conveyor for mixing. The feed ribbon mixer has the characteristics of simple structure, easy operation and uniform mixing. It can meet the mixing requirements of different types of feed and improve the efficiency of feed processing and product quality.

Feed ribbon mixers are mainly used for the mixing process in the feed production process in agriculture and animal husbandry. The following are some application scenarios of feed ribbon mixers:

1. Animal feed production: The feed ribbon mixer can be used to mix a variety of raw materials in feed, such as powder, feed additives, nutritional formulas, etc., to ensure the uniformity and consistency of the mixed feed.

2. Breeding farms: In breeding farms, feed ribbon mixers can be used to mix various feed ingredients to meet the nutritional needs of different types of animals. By adjusting the speed and time of the mixer, the proportions of different ingredients in the feed can be controlled.

3. Feed processing plants: Feed ribbon mixers are often used in large-scale feed processing plants to mix and evenly distribute different types of feed ingredients. Through the efficient mixing effect of the mixer, the quality and production efficiency of feed can be improved.

4. Planting industry: In the planting industry, the feed ribbon mixer can be used to mix plant hay, feed additives and nutritional supplements, etc., to make plant nutrient soil or mixtures for plant health care purposes.

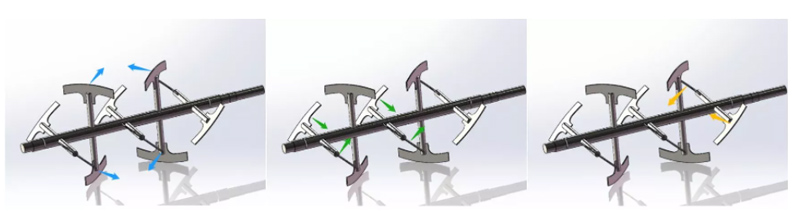

Feed ribbon mixer consists of a set of inner and outer spiral blades. When the ribbon mixer is working, the outer ribbon pushes the material from both sides to the center of the cylinder, and the inner ribbon pushes the material from the center of the cylinder to both sides of the cylinder, which is a ribbon layout. The most efficient design can form more vortex during the feed flow, thus speeding up the mixing speed and improving the mixing uniformity.

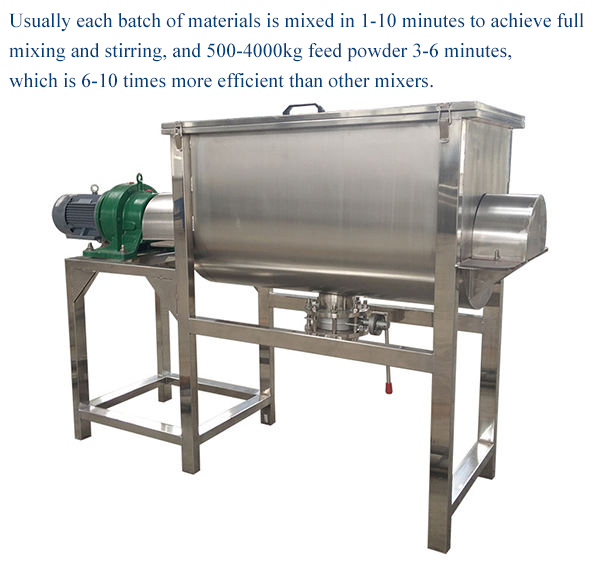

1. Usually each batch of materials is mixed in 1-10 minutes to achieve full mixing and stirring, and 500-4000kg feed powder 3-6 minutes, which is 6-10 times more efficient than other mixers.

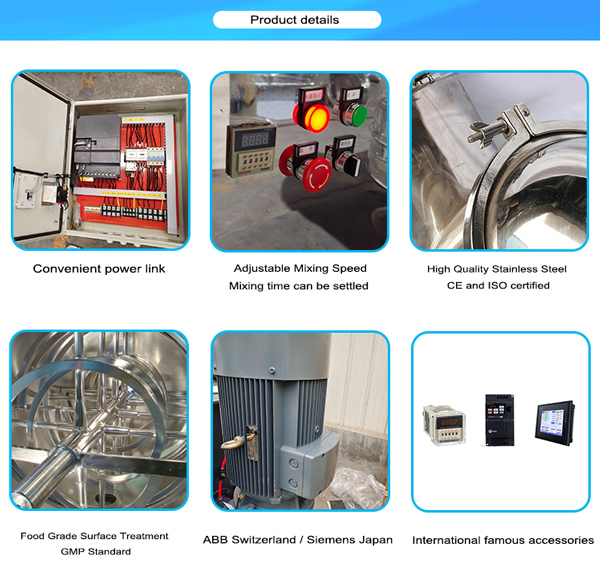

2. 304 stainless steel is used for material contact parts, with good finish, convenient operation and maintenance, and meets food-grade hygiene requirements.

3. The optimally designed two-way spiral-belt rotor has mild mixing process, high uniformity and no segregation.

4. High uniformity and no segregation.

5. It can be equipped with multiple spray atomizers to add various liquids.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The feed ribbon mixer can fully mix feed raw materials of different components to ensure the balance of feed raw materials.

Even mixing: The feed ribbon mixer drives the feed raw materials of different components to mix effectively through the rotation of spiral blades.

Improve feed quality: Through the mixing and stirring effect, various feed raw materials can be combined to make the feed quality more reliable.

Speed up production: The feed ribbon mixer adopts a fully automatic mode, which can quickly mix and stir different raw materials, speeding up feed processing.

Improve product accuracy: Feed can be added according to the proportion to ensure that each raw material can be normally stirred according to the proportion to ensure the consistency of the finished product.

There are several reasons for choosing to use a feed ribbon mixer:

1. Efficient mixing: The feed ribbon mixer uses a combination of belt conveyor and mixer to achieve continuous mixing and stirring operations, so that the feed is fully mixed evenly and improves production efficiency.

2. Basket design: The basket design of the feed ribbon mixer can ensure that the feed will not produce secondary separation and floating layer phenomena during the mixing process, improving the mixing effect.

3. Automated control: The feed ribbon mixer adopts an advanced automated control system to realize automatic feeding, mixing, unloading and other operations of feed, reducing manual operations and improving work efficiency.

4. Multi-functional application: The feed ribbon mixer is not only suitable for mixing feed, but can also be used to mix plant fibers, granules, powdery materials, etc., with strong applicability and flexibility.

Paddle mixers and ribbon mixers are both commonly used mixing equipment, but they have some differences in structure, working principle, and scope of application.

| Feature | Paddle mixer | Ribbon mixer |

| Structure | Simple, with various blades | Complex, two layers of spiral ribbons inside and outside |

| Working principle | Shear, circulating flow | Shear, tumbling, convection |

| Scope of application | Low viscosity liquid, solid-liquid mixing | High viscosity liquid, paste, powder, granular |

| Mixing effect | General | Good |

| Applicable material range | Narrow | Wide |

Henan Xinxiang Dahan Vibration Machinery Co., Ltd. has been established for 15 years, we are a manufacturing brand and supplier of powder and fine material processing equipment, our solutions focus on mixing technology, size sorting and screening.

The industries supported by Dahan Machinery are food processing, chemical and pharmaceutical. In addition to spare parts, we also supply new equipment, however, all our solutions are also designed on a project-by-project basis. This ensures unmatched quality and dependable performance.

We are proud to have accumulated decades of knowledge in the best solutions and processes for handling food, chemicals and plastic products, which has helped us become widely regarded as industry experts in our technology in these areas.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.