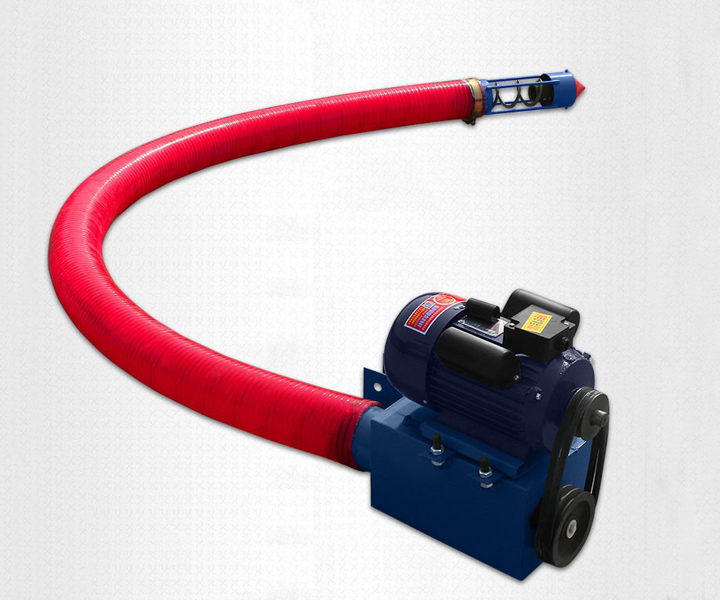

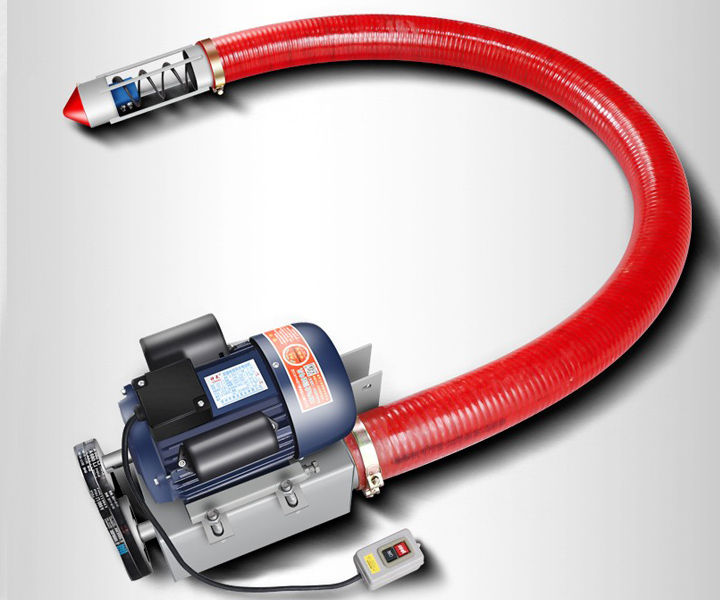

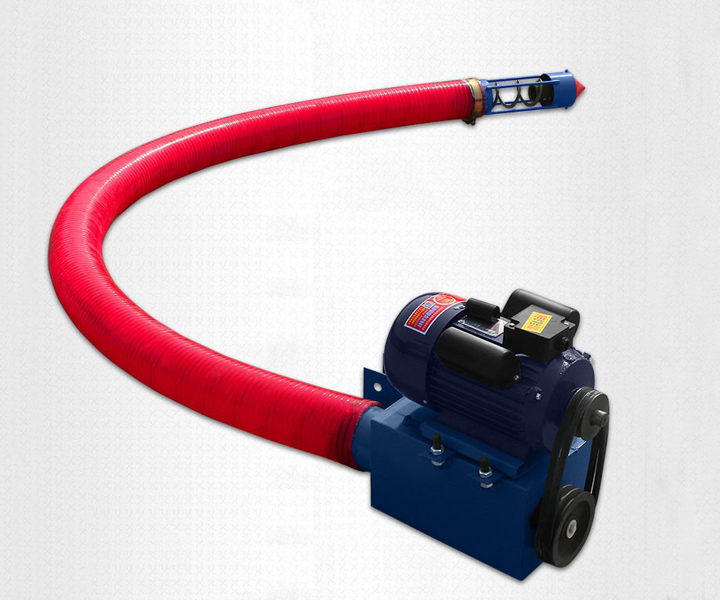

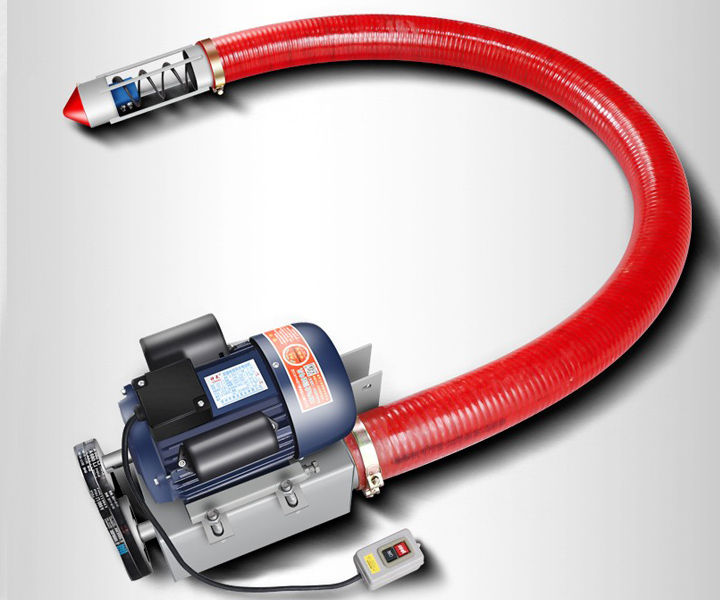

grain suction machine

grain suction machine portable grain suction machine

portable grain suction machine hand grain suction machine

hand grain suction machine vehicle-mounted grain suction machine

vehicle-mounted grain suction machine wheat grain suction machine

wheat grain suction machine

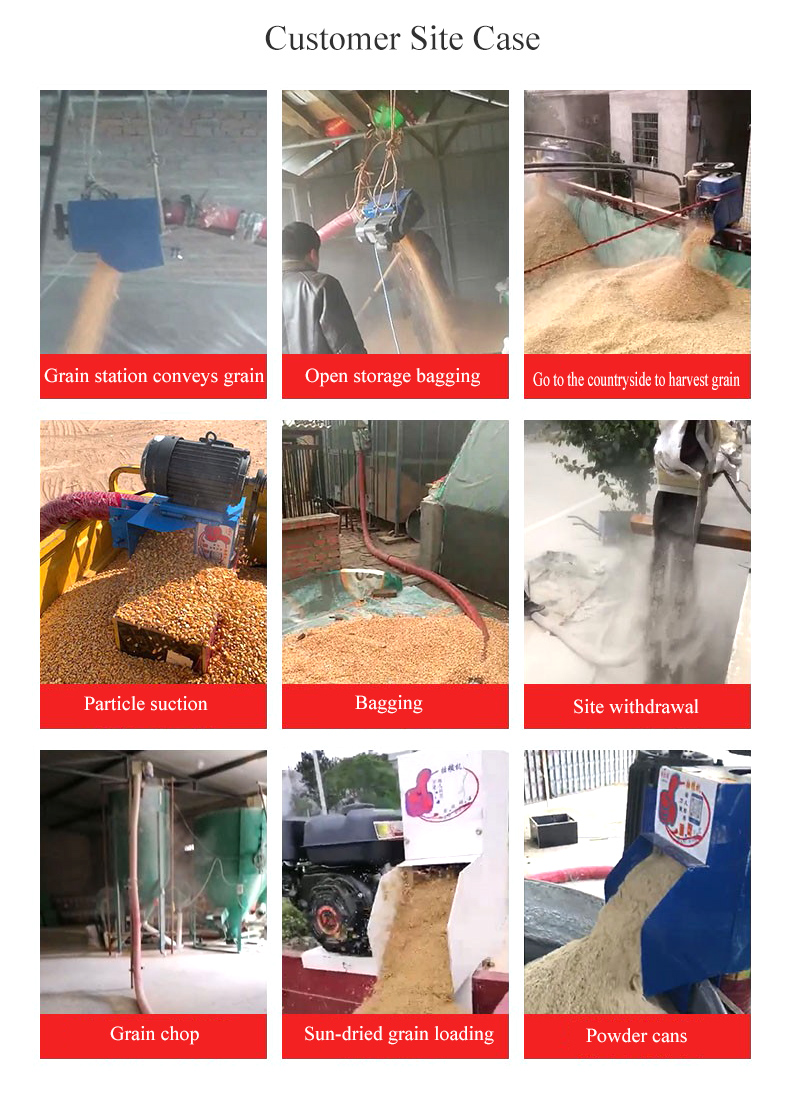

Convey all kinds of grain horizontally, inclinedly and vertically

![]()

![]()

Price:$80.00-$1000.00/Set

Consult now and enjoy a 10% discount

Length: 3-30 meters

Conveying capacity:20 tons/hour

Voltage: 220V/380V

Power: 3-7.5KW

Weight: 43-200KG

Purpose:

The grain suction machine is mainly a tool for harvesting grain. It is a small equipment specially designed for rural grain transportation, loading, stacking, and storage. It can load and unload dust and granular materials, turn warehouses, and clear warehouses. For transshipment and other tasks, Dahan grain suction machines have multiple models, ranging from 5 tons per hour to 50 tons per hour. Large ones can move freely and work in multiple locations, saving manpower and material resources.

sieve shaker for testing soil

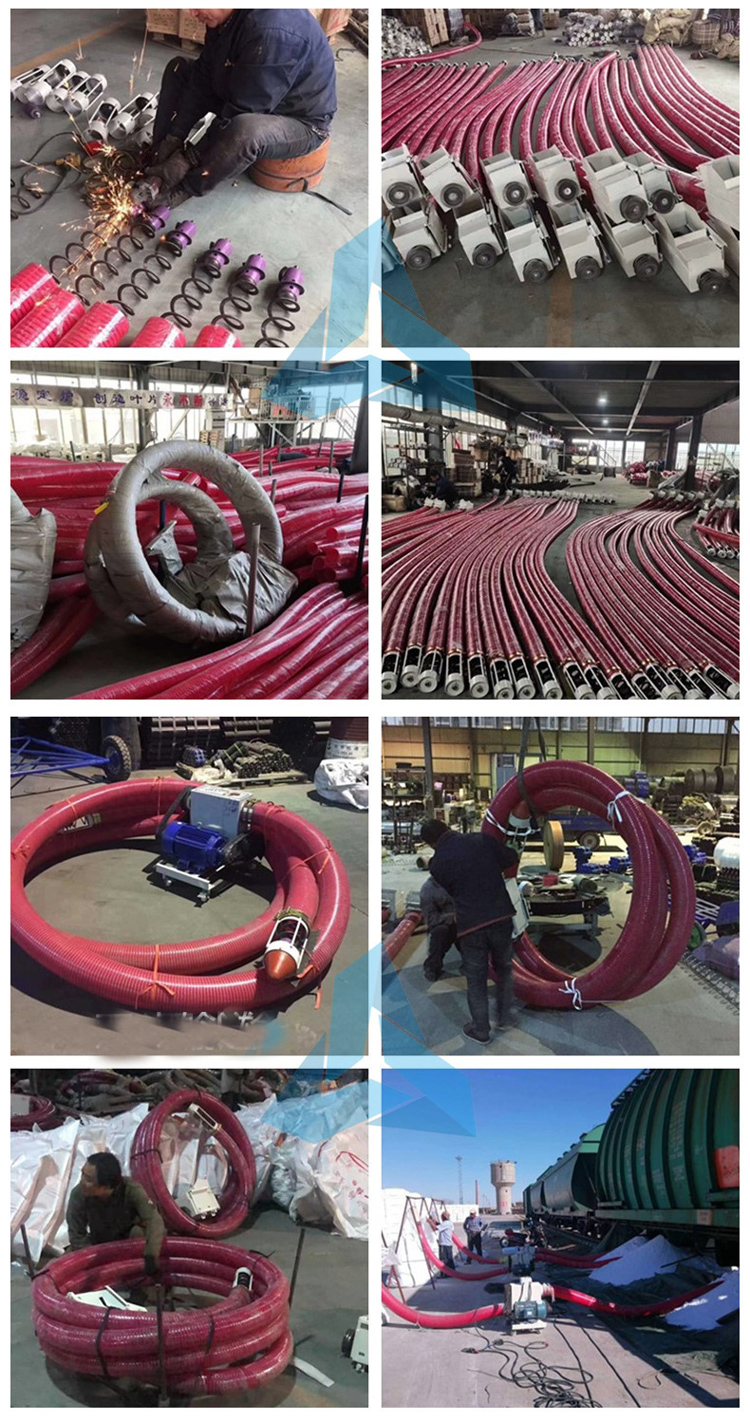

The motor shaft and the spiral spring are connected by a screw. When it starts the motor, the motor drives the spiral spring to rotate. Under the action of the rotating spring, the grain in the collecting port will rise in the direction of the spiral angle of the spring and reach the discharge port. At time, due to gravity, automatic unloading of grain.

| Diameter | Length | Voltage | Power | Capacity | Weight |

| 100mm | 3m | 220V | 3KW | 5-6T | 43kg |

| 100mm | 4m | 220V | 3KW | 5-6T | 47kg |

| 100mm | 5m | 220V | 3KW | 5-6T | 51kg |

| 100mm | 6m | 220V | 3KW | 5-6T | 55kg |

| 100mm | 7m | 220V | 3KW | 5-6T | 62kg |

| 100mm | 8m | 220V | 3KW | 5-6T | 66kg |

| 100mm | 9m | 220V | 3KW | 5-6T | 70kg |

| 100mm | 10m | 220V | 4KW | 5-6T | 74kg |

| 100mm | 11m | 380V | 4KW | 5-6T | 82kg |

| 100mm | 12m | 380V | 4KW | 5-6T | 86kg |

| 120mm | 3m | 220V | 3KW | 7-8T | 48kg |

| 120mm | 4m | 220V | 3KW | 7-8T | 52kg |

| 120mm | 5m | 220V | 3KW | 7-8T | 56kg |

| 120mm | 6m | 220V | 3KW | 7-8T | 60kg |

| 120mm | 7m | 220V | 4KW | 7-8T | 60kg |

| 120mm | 8m | 220V | 4KW | 7-8T | 71kg |

| 120mm | 9m | 220V | 4KW | 7-8T | 75kg |

| 120mm | 10m | 220V | 4KW | 7-8T | 79kg |

| 120mm | 11m | 380V | 4KW | 7-8T | 89kg |

| 120mm | 12m | 220V | 4KW | 7-8T | 93kg |

| 100mm | 20m | 380V | 7.5KW | 5-6T | 150kg |

| 100mm | 25m | 380V | 7.5KW | 5-6T | 170kg |

| 120mm | 20m | 380V | 7.5KW | 6-7T | 180kg |

| 120mm | 22m | 380V | 7.5KW | 6-7T | 200kg |

1. Wide range of applications

One machine is multi-purpose, it can suck grain as well as granular fertilizer, feed, chemical products and other non-corrosive granular materials.

2. High conveying efficiency

The whole machine can be produced with a length of 3-15 meters, and the conveying capacity can reach 20 tons per hour. It can also be customized according to the user's conveying requirements.

3. Can be used in combination

It can be operated by a single unit, combined with multiple units, or can be combined with other equipment to form a conveying system to meet different requirements.

4. Easy to operate

The whole machine is light in weight, small in area, and convenient to move and install.

Grain suction machine for grain

Grain suction machine for paddy

Car grain suction machine for rice

The grain suction machine is very suitable for individual farmers, professional grain households and agricultural cooperatives. It can also be used in the occasions of conveying pellets, such as breeding farms, feed factories, food factories, and plastic factories. It can transport grains such as wheat, soybeans, corn, rice, sorghum, plastics, resins, and rice. It can be transported horizontally and inclinedly. Compared with any shipping method, the shipping cost is lower.

The grain suction machine produced by Dahan Machinery has a length of 3-30 meters and can suck 2-20 tons of grain per hour. The weight of the machine is about 60 kilograms. The machine uses a power supply of 220V single-phase power/380V three-phase power. The product models are complete and can absorb grain. The machine can be customized according to customer requirements.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.