Relying on drum screens to help material separate, it is highly effective in separating and processing wood chips, topsoil, compost, light demolition waste and household waste.

![]()

![]()

![]()

Price:$800.00-$5,000.00 /Set

Consult now and enjoy a 10% discount

Mesh size: 16mm×12mm

Mesh size: 2-80mm

Feed size: ≤300-400mm

Cylinder speed: 16-20 rpm

Drum angle: 8°-16°

Capacity: 50-800 tons/hour

Motor power: 2.2-45kw

Application: Mainly used in mineral and solid waste treatment industry.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

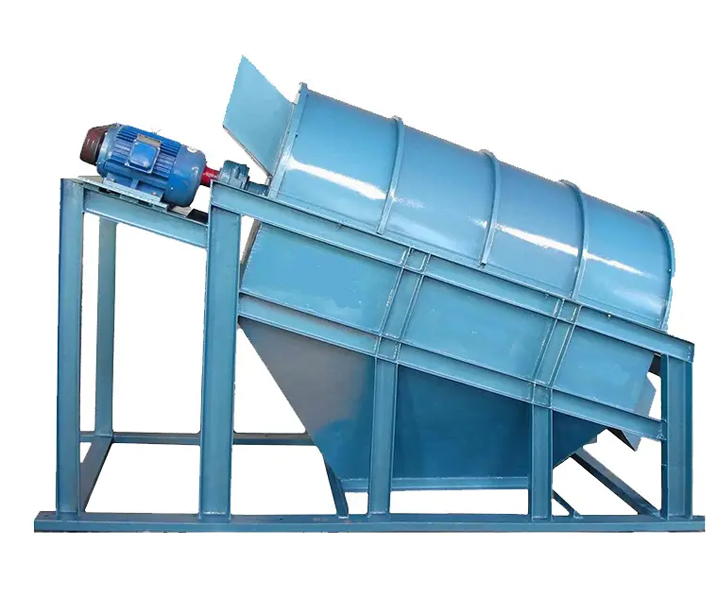

Trommel screen, also known as a rotary screen or drum screen, is a mechanical screening machine used to separate materials by size. It consists of a cylindrical drum that is usually elevated at an angle at the feed end. The drum rotates, and as the material enters the drum, the smaller particles pass through the openings in the screen, while the larger particles are retained inside the drum and discharged at the end.

Trommel screens are commonly used in the mining, waste management, and composting industries. They are ideal for separating materials such as soil, rocks, sand, and other aggregates. The screen size can be customized based on the specific application and the desired output size.Trommel screens are designed to be highly efficient and require minimal maintenance. They can handle large volumes of material and are often used in conjunction with other processing equipment, such as crushers and shredders.

Mobile trommel screen: Suitable for situations where frequent transfer of work locations is required, such as mining sites, construction sites, etc. It is usually equipped with wheels or tracks to facilitate movement between different workplaces.

Shafted trommel screen: The trommel is equipped with a central shaft support, which makes the trommel more stable during rotation. It is suitable for situations where larger amounts of materials are processed, such as ore screening.

Shaftless trommel screen: The trommel has no central shaft support, and the overall structure is simpler. It is suitable for some occasions that do not have high requirements on the equipment structure, such as screening of light granular materials.

Large trommel screen: It is suitable for processing large amounts of materials. It has large screening capacity and processing capacity. It is often used in mining, building materials and other industries.

Small trommel screen: It is suitable for processing a small amount of materials or in situations where space is limited. The structure is relatively light and easy to transport and install. It is often used in laboratories, small production lines and other places.

Double layer trommel screen: It has two layers of screen mesh, which can conduct coarse and fine screening of materials at the same time to improve screening efficiency. It is widely used in fields that require multi-stage screening, such as ore processing, building materials, etc.

The trommel screen works by rotating a cylindrical drum that is typically elevated at an angle. As the drum rotates, materials are fed into the drum at the feed end. The material then tumbles inside the drum, and the smaller particles fall through the openings in the screen, while the larger particles are retained inside the drum and discharged at the end.

Efficient screening

Designed to efficiently screen large volumes of material. The rotating drum and customizable screen size can effectively screen different sizes of materials, making the process faster and more efficient, with a screening efficiency of over 95%.

Material separation

Material can be efficiently separated by size, allowing separation of smaller and larger particles. This is useful in recycling and waste management applications where different materials need to be separated for further processing or disposal.

Versatility

Can be used to screen a wide variety of materials including soil, sand, rock and other aggregates. They can also be used in various industries such as mining, waste management and composting.

Low maintenance

Low maintenance costs make it a cost-effective solution for screening applications. They are simple in design and require minimal maintenance, reducing downtime and repair costs.

Customizable

Can be customized to meet specific screening requirements such as sieve size, sieve shape and drum size. This makes them a versatile and adaptable solution for a wide variety of screening applications.

Reduce noise and dust

Designed to reduce noise and dust emissions, making it a greener solution for screening and processing applications.

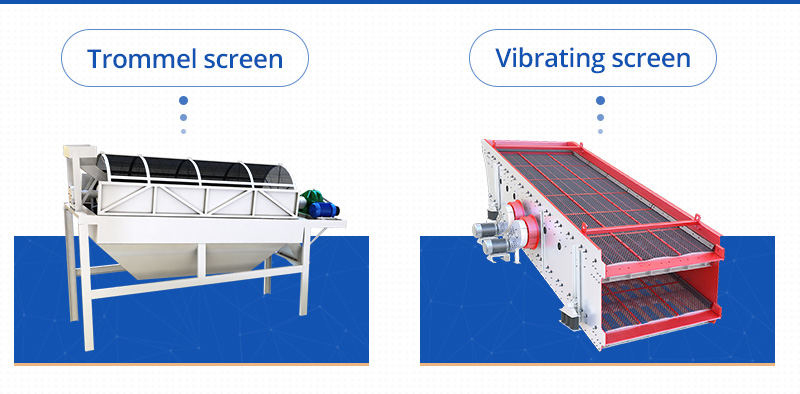

| Compared | Trommel Screen | Vibrating Screen |

| Screening method | During the screening process, the equipment will not vibrate, but generally the motor and reducer will drive the roller to rotate through the bearing. The material in the roller will pass through the screen from high to low due to the rotation of the roller, and will be successfully screened out, which belongs to the rolling screen. point. | Screening using the exciting force generated by the vibrating motor belongs to vibrating screening, and the material can be screened in multiple stages through multi-layer screens. |

| Screening effect | t is suitable for dusty, small particles, and wet materials. It overcomes the screen sticking problem that occurs when various vibrating screens screen wet materials, and improves the output and reliability of the screening system. | It is more suitable for the screening of bulk materials; the screening accuracy is relatively low, but the equipment wear is small and the service life is long |

| Screening congestion | The material rolls in the screen with the movement track of the roller, which can make the material stuck in the screen hole fall out, or be ejected by the free-falling material, so generally the screen is rarely blocked. | The vibrating screen relies on the vibration of the screen to screen the material. The vibration frequency is fixed. If the material is stuck in the screen hole, it is difficult to remove it by its own strength. Therefore, after a period of use, the machine will be shut down to clean the clogged screen holes, or the net cleaning device will be installed to prevent the screen holes from being clogged. |

Trommel Screen for sawdust

Trommel Screen Waste Separation

| Model | Screen Diameter(mm) | Screen Length(mm) | Mesh size(mm) | Max feeding size(mm) | Capacity(t/h) | Power(kw) |

| GTS0618 | 600 | 1800 | 2-80 | <300 | 0.5-1.0 | 1.1 |

| GTS0824 | 800 | 2400 | 2-80 | <300 | 5-30 | 2.2 |

| GTS1030 | 1000 | 3000 | 2-80 | <300 | 20-100 | 4 |

| GTS1236 | 1200 | 3600 | 2-80 | <300 | 30-120 | 7.5 |

| GTS1545 | 1500 | 4500 | 2-80 | <300 | 60-280 | 11 |

| GTS1860 | 1800 | 6000 | 2-80 | <300 | 80-350 | 22 |

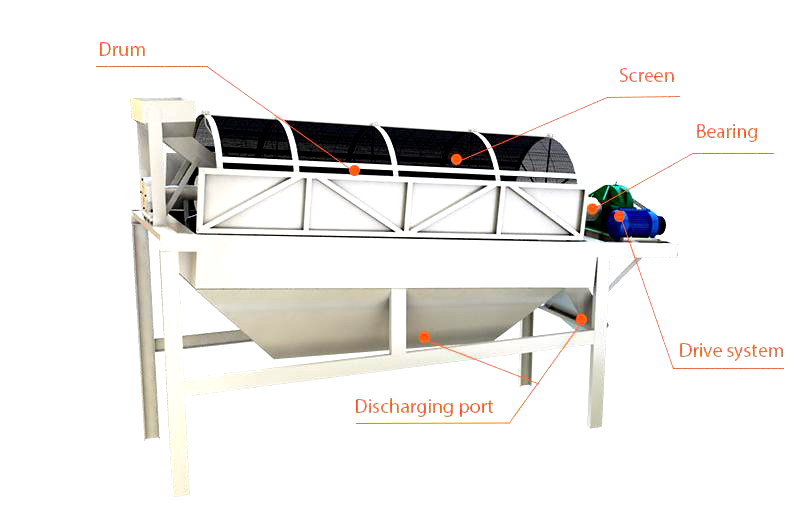

The structure of a trommel screen consists of several key components that work together to screen materials efficiently. Here are the main components of a trommel screen:

Drum: The drum is the main component of the trommel screen and is typically made of steel. It is a cylindrical structure that rotates about its axis, and is inclined at an angle to allow materials to tumble inside.

Screen: The screen is attached to the inside of the drum and is typically made of mesh or perforated metal. The size of the openings in the screen can be customized to suit the specific application and desired output size.

Feed hopper: The feed hopper is located at the top of the drum and is used to load materials into the trommel screen.

Discharge chute: The discharge chute is located at the end of the drum and is used to discharge screened materials onto a conveyor or into a container.

Drive system: The drive system is used to rotate the drum and is typically powered by an electric motor, gearbox, or chain drive.

Support structure: The support structure is used to hold the drum and other components in place, and is typically made of steel or other durable materials.

Cleaning system: Trommel screens may include a cleaning system, such as a brush or spray bar, to keep the screen clean and prevent blockages.

There are several options available for trommel screens to customize them for specific applications. Here are some of the most common options:

Screen size: Can be customized with different screen sizes, allowing for the separation of materials of different sizes.

Screen material: Can be fitted with screens made of different materials, such as woven wire, mesh, or perforated plates, to suit the specific application and material being screened.

Drum size: Can be customized with different drum sizes to accommodate varying processing capacities and throughput requirements.

Drum material: The material of the drum can be customized, with options including steel, rubber, or urethane, depending on the specific application and material being screened.

Infeed and discharge conveyors: Trommel screens can be equipped with infeed and discharge conveyors to automate the screening process and improve efficiency.

Spray bars: Spray bars can be added to the trommel screen to wash the material being screened and prevent blockages.

Agitators: Agitators can be added to the drum to help break up clumps of material and improve screening efficiency.

Dust covers: Trommel screens can be fitted with dust covers to reduce dust emissions and improve the working environment.

Trommel screen is mainly used to classify the particle size of materials. It has outstanding advantages in screening wet and adhesive materials. It can achieve the purpose of not sticking to the screen and not blocking holes. It is widely used in metallurgy, building materials, chemicals, food, etc. Screening of dry powder or granular materials in pharmaceutical, abrasive and fertilizer industries, especially suitable for dry production of machine-made sand, and can also be used for granular wet material screening.

1. In the stone quarry, it is used for grading large and small stones and separating soil and stone powder.

2. It is used for sand and gravel separation in sand and gravel fields.

3. The coal industry is used for the separation of lump coal and pulverized coal and for coal washing (a component of coal washing machinery).

4. The chemical industry and mineral processing industry are used for the classification of large and small blocks and the separation of powdery substances.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.