It can realize drying and vertical conveying functions simultaneously. During the conveying process, the material is not impacted by mechanical force, which is suitable for lossless conveying occasions.

![]()

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

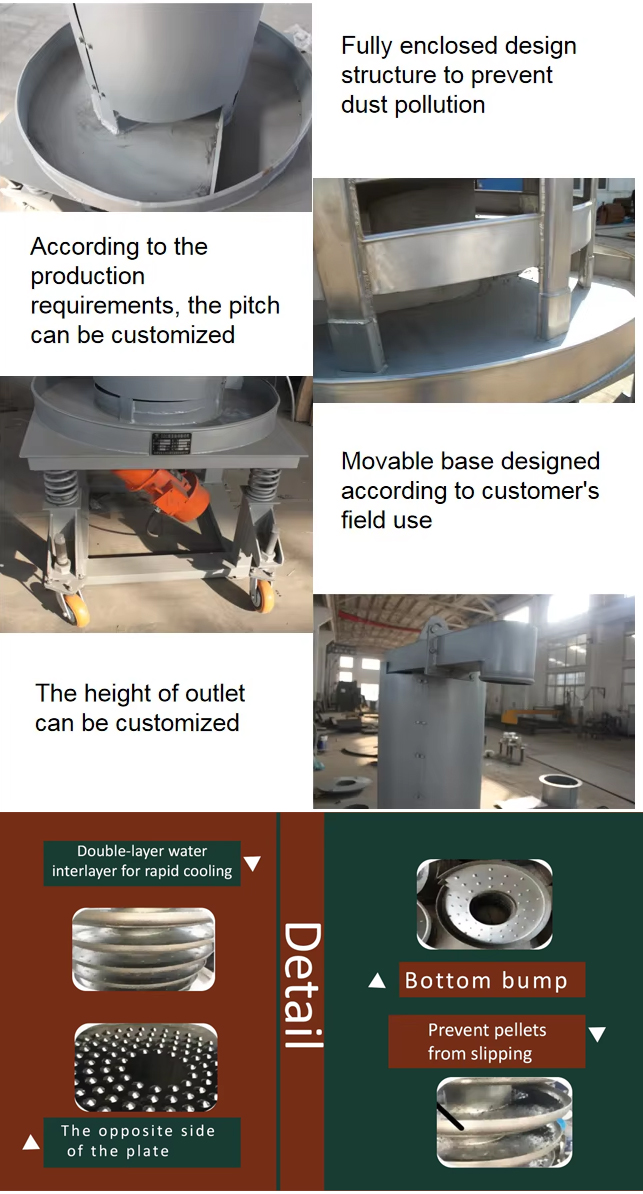

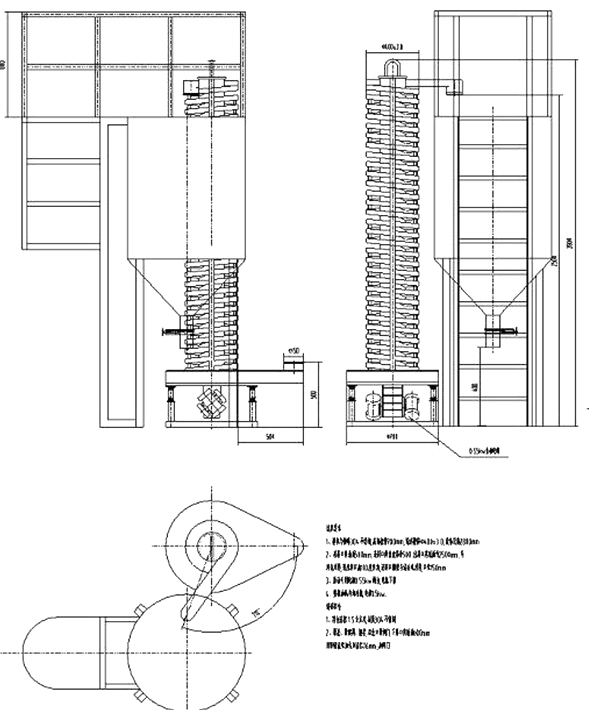

Conveyor trough diameter: 300-900mm

Height: ≤6 meters

Feeding capacity: 3.5 tons/hour

Type: Fan

Dryer coefficient: Hot air

Frame material: SUS304/Carbon Steel

Application: Suitable for occasions that require vertical lifting, cooling and drying, such as food processing, chemical industry, agriculture, glass processing, ceramic production, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

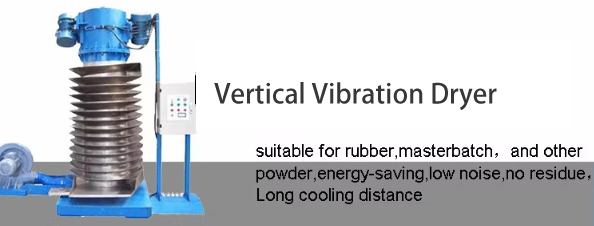

Vertical vibration dryer, also called spiral vibration elevator dryer conveyor, is designed for rapid cooling, drying and lifting of materials. It uses a fan to dry and cool materials through the holes on the center column. It is suitable for cooling and drying high-temperature materials in modified plastic production lines. It can provide a vibration conveyor with a conveying capacity of 500-4000kg/h.

Vertical vibration dryer is a standard equipment for lifting bulk materials in many industries. It can convey, dry and cool plastic particles, rubber particles, chemical and pharmaceutical intermediates, metal salts, solder powder, glass ingredients, catalysts, abrasives and ash as well as milk powder, coffee powder, tea, nuts, nutrients and grains.

Vertical vibration dryer combines drying, cooling and vertical conveying functions. The specific functions include:

Drying materials: By introducing hot or cold air and vertical vibration, the moisture in the material is accelerated to evaporate, and the granular or powdered materials are dried.

Cooling: By introducing a fan system, the temperature of the material can be reduced and the material can be quickly cooled. It is suitable for occasions where the material needs to be cooled.

Vertical conveying: The vertical conveying function of the elevator can effectively transport the material from the bottom to the top or the opposite direction, realizing the vertical conveying and lifting of the material.

Vertical vibration dryers come in various types based on their design and functionality. Some common types of vertical vibration dryers include:

Fan Type Vertical Vibration Dryer

Output: 500-4000kg/h

Cooling method: fan blowing

Purpose: Use the fan to dry and cool the material through the holes on the center column, used in the production of engineering plastics.

Water Cooling Type Vertical Vibration Dryer

Output: 500-4000kg/h

Cooling mode: Supply 25℃ industrial water

Purpose: Mainly used in occasions where materials need to be cooled and solidified, such as candy, chocolate, etc. in the food industry.

Steam Jacket Type Vertical Vibration Dryer

Output: 500-4000kg/h

Heat transfer medium: steam

Purpose: Suitable for occasions where high-temperature drying is required, such as high-temperature drying of powdered and granular raw materials in the chemical industry.

Material Loading: Bulk materials are fed into the dryer from the top.

Vibration Action: The vertical vibration causes the material to move and mix, ensuring uniform exposure to heat.

Air Flow: Hot air is circulated through the material, evaporating moisture.

Discharge: Dried material is collected at the bottom of the dryer.

Multifunctional

A dual-purpose dryer that can simultaneously realize the functions of drying, cooling and vertical conveying.

Low breakage rate

The material is not impacted by mechanical force during conveying, which is suitable for lossless conveying occasions.

Uniform drying

The material moves continuously during vibration, no material is retained, the heating time is stable, and the drying is uniform.

Strong versatility

It can be designed as upper feeding and lower discharging or lower feeding and upper discharging, and the height can be customized according to customer requirements.

Reduce agglomeration

Vertical vibration can effectively prevent the material from agglomerating during the drying process, maintain the gap between the material particles, and avoid affecting the drying effect due to agglomeration.

Easy operation

Vertical vibration dryer is usually simple in design, easy to operate and maintain, provides stable drying effect, and reduces the need for manual intervention.

| Items | Unit | LSZ1050 | LSZ1200 |

| Groove diameter | mm | 1050 | 1200 |

| Groove width | mm | 240 | 400 |

| Groove height | mm | 1600 | 1600 |

| Material running distance | mm | 35000 | 50000 |

| Helical pitch | mm | 110 | 110 |

| Width of inlet | mm | 650 | 650 |

| Height of inlet (From the ground level)mm |

mm | 300 | 300 |

| Width of outlet | mm | 245 | 245 |

| Height of outlet (From the ground level) |

mm | 1650 | 1650 |

| Conveying Speed (adjustable) |

m/min | 6~8 | 6~8 |

| Motor power | kw | 0.75*2 | 1.1*2 |

| Motor power for cooling fan | kw | 3.7 | 3.7 |

| External Dimension | m | 2.15*1.35*2.56 | 3*1.5*2.56 |

| Total weight | T | 1.2 | 1.5 |

Vertical vibration dryer usually consists of the following main components:

Elevator body: This is the main structure of the entire equipment, usually a vertical barrel or cylindrical container for holding the material to be dried.

Vibration system: The vibration system usually consists of a vibration motor, a vibrator, etc., which is used to generate vertical vibration force to promote the uniform heating and drying of the material during the lifting process.

Fan system: The fan system includes a fan and an air duct, which is used to introduce hot or cold air to take away moisture from the material and accelerate the drying process.

Heating system: Used to heat the air in the air duct, provide the required drying temperature, and promote the rapid drying of the material.

Feed port and discharge port: The equipment is usually equipped with a feed port and a discharge port for loading and unloading the material to be dried.

Support structure: Structural components that provide stability and support for the equipment to ensure safe operation of the equipment.

Food industry: Drying of grains, cereals, nuts and snacks.

Pharmaceutical industry: Drying of active pharmaceutical ingredients (API) and granules.

Chemical industry: drying of powders, pigments and granular materials.

Agricultural industry: drying of seeds, fertilizers and agricultural products.

Other industries: Drying of plastics, minerals and other industrial materials.

The Vertical Vibration dryer is a valuable asset in industrial drying processes, efficiently and evenly drying a wide range of materials. With its unique vertical design, gentle handling, fast drying capabilities and customizable features, the Vertical Vibrating Dryer is a versatile solution for industries seeking high-quality and efficient drying solutions.

| Application scenarios | Materials | Application | Delivery capacity (kg/h) |

Vertical height (m) |

Other instructions |

| Food industry | Grains (wheat, corn, etc.) | Drying, conveying to the grinding process | 5000 | 5 | Preheat and then convey to improve grinding efficiency |

| Feed industry | Soybean meal, fish meal | Drying, mixing | 3000 | 3 | Link with mixing equipment to prepare mixed feed |

| Chemical industry | Plastic granules (PP, PE) | Cooling, conveying to the molding machine | 8000 | 2 | Quick cooling of high-temperature particles from the extruder |

| Mining industry | Ore powder | Drying, conveying to the mineral processing process | 10000 | 4 | Open-pit mine, harsh environment, requires durable equipment |

| Pharmaceutical industry | Chinese herbal medicine powder | Drying, conveying to the packaging process | 2000 | 8 | GMP certified workshop, requires hygienic cleaning |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.