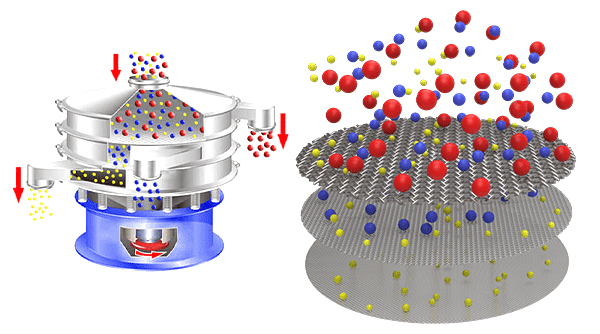

It can be used to screen dry powder or granular products as well as wet products and liquids by using customized layered sieves and 3D motion to screen products

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Screen frame: 1-5 layers (3 layers is best)

Material: Q235 carbon steel, stainless steel 304 or 316L, polypropylene plastic

Motor power: 0.25Kw to 2.2Kw or customized

Power supply: 220/240/380/415/450V can be used. 50 or 60HZ.

Application: Commonly used in a variety of industries including food processing, pharmaceuticals, chemicals, plastics and minerals

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Vibrating sieve, also known as a vibrating screen or vibratory sieve, is a machine that is used to separate and classify particles based on their size and shape. As material to be screened is fed onto the screen, vibrations cause particles to move and bounce across the screen surface. Smaller particles pass through the screen and are collected in a container below, while larger particles remain on top of the screen and are discharged at the end of the machine.

The vibrating sieve is especially suitable for separating and classifying materials with various particle sizes, as well as removing oversized particles or impurities from materials. Vibrating screens are available in a variety of sizes and designs, from 400mm to 2000mm, to meet the screening needs of different industries, with an output of 100 to 3300kg/h, widely used in food and beverage, pharmaceuticals, paper and pulp, metal powder, powder coating and other industries, and can be fully customized according to your application.

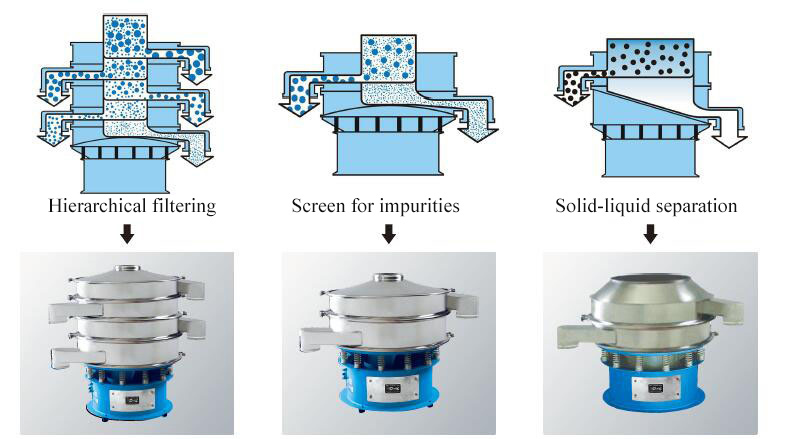

Vibrating sieve is based on particle size and shape for separation and classification. The main function of the vibrating screen is to remove oversized particles and impurities in the screened material.

Key features include:

1. Separation and classification: Separation and classification are carried out according to the size and shape of the particles to ensure that the final product quality is consistent and meets the required specifications.

2. Removal of impurities: Remove oversized particles and impurities in the screened material, resulting in a higher quality, purer product that is safe to eat or use.

3. Solid-liquid separation: quickly remove insoluble solids in various slurries, and remove unqualified impurities or suspended solids in slurries.

Efficient Particle Separation

Vibration is used to make particles move and bounce on the screen surface, and efficient separation is carried out according to the size and shape of particles. This results in a high level of separation precision and efficiency.

Improve product quality

By removing oversized particles and impurities from the material, vibrating screens can improve the quality and purity of the final product, ensuring it meets required specifications.

Multi-layer screening

By using custom-made layered sieves and 3D motion to screen products, up to 5 stages of product separation can be performed in just 1 operation.

High pass rate

Can handle large volumes of material and can operate at high throughput rates, making it suitable for industrial-scale production.

Easy to maintain

Easy maintenance with simple controls and easy access to screens for cleaning or replacement.

Versatility

Vibrating screens are available in a variety of sizes and designs, with different screen sizes and mesh materials to suit different applications and material types.

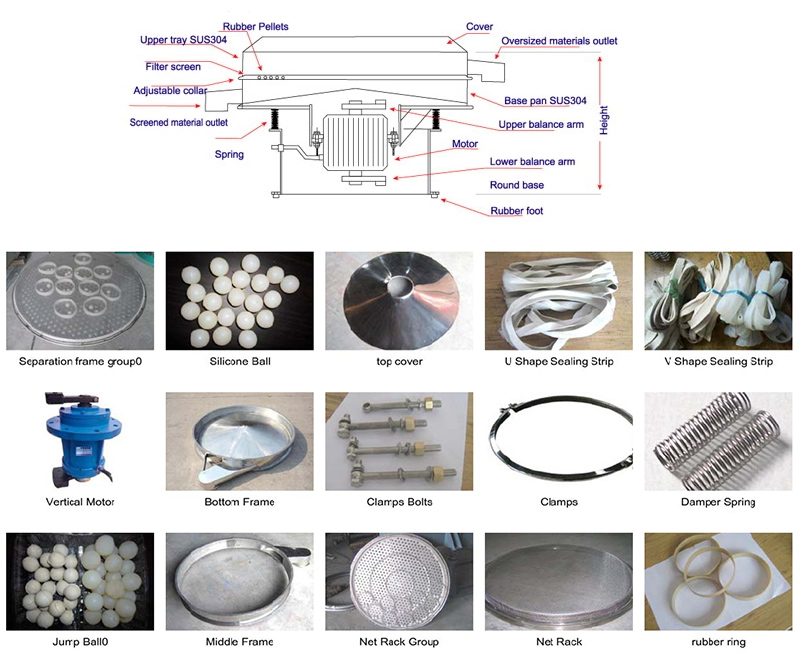

Vibrator sieve uses YZUL vertical vibration motor as the excitation source. The eccentric weight at the upper and lower ends of the vibration motor converts the rotational motion into a horizontal, vertical, and inclined three-dimensional motion, and transmits it to the screen surface of the rotary vibrating screen; It enters the equipment through the inlet. According to different material screening requirements, the material passes through 1-5 layers of different mesh metal woven screens. In this process, the cleaning screen is located under the screens of each layer . The device (bouncing ball) continuously hits the stainless steel screen through frequency vibration, so that the materials on the screen can be smoothly screened through the mesh, and effectively solve the problem of material blockage. The materials of different meshes pass through the screens of the corresponding meshes of each layer. After the net, it is discharged at the discharge port of each layer, and finally achi eves the purpose of screening and removing impurities or filtering and grading.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Vibrator sieves can be customized to suit specific applications and material types. Here are some examples of vibrator sieve customizations:

| Special Design | Design Brief | Image |

| Standard type | The three-dimensional rotary vibrating screen has a variety of models to choose from. It can filter solids and liquids or carry out size classification and impurity removal on dry materials. |  |

| Edge type | The specially designed flanged type is a model with large feeding capacity, prevents material splashing, and is easy to observe the screen. |  |

| Gate type | There is a gate-type design for the processing of special materials to ensure the processing accuracy of difficult-to-screen materials and increase the processing capacity. |  |

| Ultrasonic | Equipped with an ultrasonic screening system, a sharp tool for fine powder screening, to solve the problem of mesh blocking, so that the mesh is truly not blocked. |  |

| Inline type | Special design, huge processing capacity, easy to combine with production lines, good at screening flour, starch, washing powder, additives, etc. |  |

| Anti-corrosion type | The part in contact with the material is made of polypropylene (PP plastic), and it has a solution for screening corrosive materials such as carbon steel and stainless steel. |  |

| Explosion-proof | The whole machine has better sealing and adopts BZDL explosion-proof vertical vibration motor to meet the higher requirements of special industries. |  |

| High frequency type | Using a high-frequency vibration motor (3000RPM) as the excitation source, it is good at filtering materials such as ceramic glazes. |  |

Note: It is inconvenient to display more models one by one. Dahan Machinery can customize the most suitable vibrator sieve according to your needs.

1. Screen size: The screen size of the vibrator sieve can be customized to suit the particle size distribution of the material being screened. This ensures that the screens are optimized for maximum separation efficiency.

2. Mesh material: The mesh material can be customized to suit the specific performance of the screened material. For example, a finer mesh material can be used for powders, while a coarser mesh material can be used for larger granules.

3. Sieve plate configuration: can be customized according to the specific requirements of the application. For example, a single-layer configuration can be used for simple particle separation, while a multi-layer configuration can be used for more complex separation requirements.

4. Motor speed and power: Motor speed and power can be customized to meet the throughput requirements of the application. Larger volumes of material may require higher motor speeds and power, while smaller volumes may require lower motor speeds and power.

5. Materials of Construction: Materials of construction can be customized to meet the specific requirements of the application. For example, stainless steel can be used in food and pharmaceutical applications, while carbon steel can be used in industrial applications.

| Diameter | 400mm/600mm/800mm/1000mm/1200mm/1500mm/1800mm | |

| Layer | 1-5 | |

| Mesh size | 2-325mesh | |

| Material | carbon steel/stainless steel/plastic | |

| Screen cleaning way | Only sieve (don't have other screen cleaning device) | for coarse material which is easy to sieve or used for filter |

| Bouncing balls | used for coarse material and easy to sieve | |

| Ultrasonic system | used for fine,light material and easy adsorption | |

| Rotary brush | used for some easy to conglomerate and viscosity material | |

| Voltage | 3 phase, 380V, 50HZ or 3 phase, 415V, 50HZ or others can be customized | |

| Warranty | 12months except the easy wear parts | |

Chemical industry: resin powder, paint, washing powder, micro powder, paint, soda ash, lemon powder, rubber, plastic, etc.

Abrasives, ceramics industry: alumina, quartz sand, mud, spray soil particles.

Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar, etc.

Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, welding rod powder, etc.

Pharmaceutical industry: Chinese medicine powder, Chinese medicine liquid, western medicine powder, western medicine liquid, Chinese and western medicine granules, etc.

Papermaking industry: coating paint, clay slurry, black and white liquid, waste liquid, papermaking liquid, waste water recovery.

Environmental protection: garbage, human and animal manure, waste oil, food wastewater, wastewater processing, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.