For a 100-ton slag cement waste transfer and loading truck, choosing the appropriate slag cement waste transfer equipment can involve either an inclined belt conveyor or a grain conveyor. Depending on the conveying distance and inclination angle, an inclined belt conveyor can transport over 100 tons per hour and can reach an inclination angle of 45°, while a grain conveyor can reach an inclination angle of 90°.

The choice of either an inclined belt conveyor or a grain conveyor for a 100-ton slag cement waste transferred and loaded truck depends on the actual operating conditions. Inclined belt conveyors offer a high conveying capacity, handling over 100 tons of material per hour. With a special patterned belt surface, they can reach an inclination angle of up to 45°. They are suitable for efficient medium- and long-distance transportation, with low energy consumption and excellent continuous operation stability. Grain conveyors, on the other hand, utilize pneumatic conveying principles, enabling vertical lifts up to 90°. They offer flexible layouts and a fully enclosed process with no dust leakage, making them particularly suitable for applications with limited space or stringent environmental requirements. However, they have a relatively low handling capacity and high energy consumption.

When loading a 100-Ton Slag Cement Waste Transfer and Loading Truck, choosing a pneumatic suction machine offers significant advantages, particularly its exceptional flexibility in conveying distances. Horizontal conveying distances can reach up to 30 meters, and vertical lifting distances can reach 10 meters or more. All conveying processes utilize a fully enclosed stainless steel or carbon steel system, ensuring excellent corrosion resistance and durability while completely preventing dust leakage. This enclosed design is particularly suitable for handling powdered materials such as slag cement, maintaining clean operation and meeting strict environmental requirements. Furthermore, its maneuverability allows it to be drawn directly from the stockpile without additional equipment, significantly reducing labor costs and minimizing material loss during transfer. A range of power options are available, including motors, power supplies, and diesel engines.

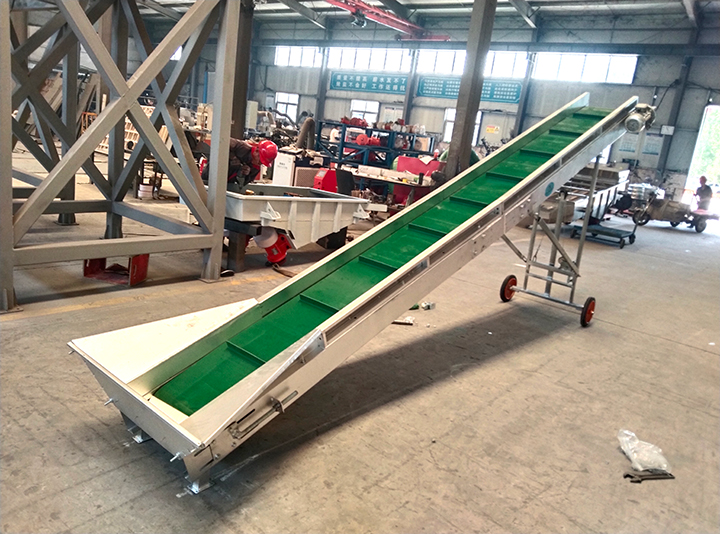

An inclined belt conveyor was chosen to transfer and load 100 tons of slag and cement waste. Its high-strength rubber belt surface and corrosion-resistant steel frame structure are capable of withstanding the long-term wear of abrasive materials. Suitable for horizontal and inclined conveying distances exceeding 50 meters, with a maximum inclination angle of 18-22° (up to 45° with a special baffle design), it achieves efficient, continuous conveying of over 100 tons per hour. Its power consumption is far lower than that of pneumatic systems, significantly reducing operating costs. Its robust and reliable structure and simple maintenance make it particularly suitable for fixed-route, high-capacity, and energy-sensitive industrial applications.

The 100-Ton Slag Cement Waste Transfer and Loading Truck process typically begins at a stockpile or silo, where material is retrieved by heavy equipment such as an inclined belt conveyor or an enclosed grain conveyor. Belt conveyors are suitable for high-capacity conveying along fixed paths, with a maximum inclination angle of 22° (which can be increased to 45° with special baffle designs), handling over 100 tons per hour. Grain conveyors utilize pneumatic conveying for fully enclosed, dust-free operation, making them particularly suitable for applications with limited space or stringent environmental requirements. After being lifted and transferred to the loading point by the conveyor equipment, the material is precisely loaded into the truck bed via an adjustable chute. Dust emission and material fragmentation must be controlled throughout the entire process to ensure the safe transportation of the waste to a disposal site or recycling facility.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.