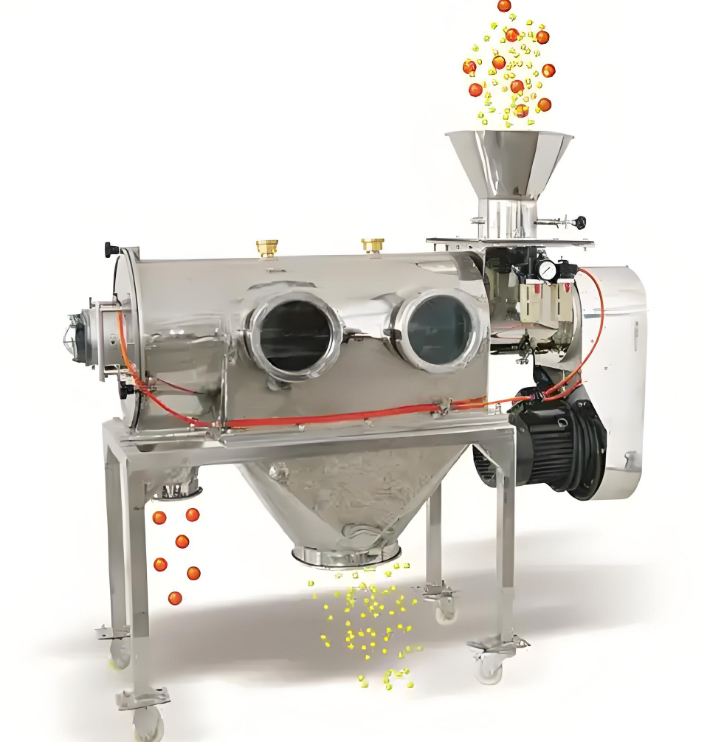

The Centrifugal Sieve Machine, leveraging its high-speed rotation to generate powerful centrifugal force, enables high-precision screening operations, achieving a sieving fineness of up to 800 mesh (approximately 20 microns). It is suitable for applications with stringent particle size requirements, such as fine chemicals and high-purity powders. In standard configurations, hourly throughput varies depending on material characteristics (such as specific gravity, flowability, and moisture content) and the mesh size, typically ranging from 500 kg to 5 tons. Design optimization can even achieve higher throughput for lightweight or highly fluid materials.

When selecting a machine, if the material is prone to static electricity, agglomeration, or requires extremely high screening accuracy, consider cyclone or airflow sieves as alternatives. Cyclone sieves utilize a rotating impeller to generate negative suction, which synergizes with centrifugal force. They are particularly effective at processing lightweight, fibrous materials and offer enhanced anti-clogging capabilities. Airflow sieves, on the other hand, rely solely on airflow energy to transport and drive the material through the sieve, with virtually no moving parts. They are ideal for ultrafine powders with extremely high hygiene requirements or those prone to explosion.

The core strengths of a Centrifugal sieve machine lie in its high processing capacity and continuous operation. Its continuous feed and discharge design allows for easy integration into automated production lines, enabling 24-hour uninterrupted operation. Its throughput per unit time is significantly higher than that of a similarly sized intermittent vibrating screen. Furthermore, the machine exhibits excellent anti-clogging performance. The centrifugal force generated by high-speed rotation and the built-in sweeping arm create a strong self-cleaning effect on the screen, effectively handling sticky, fibrous, or easily agglomerated materials. Furthermore, the powerful centrifugal force forces particles to fully and quickly contact the screen, ensuring high screening accuracy. This makes it particularly suitable for classifying fine powders such as flour and metal powders. Its compact and fully enclosed vertical structure not only takes up little space but also perfectly meets the dust control requirements of industries such as food and pharmaceuticals.

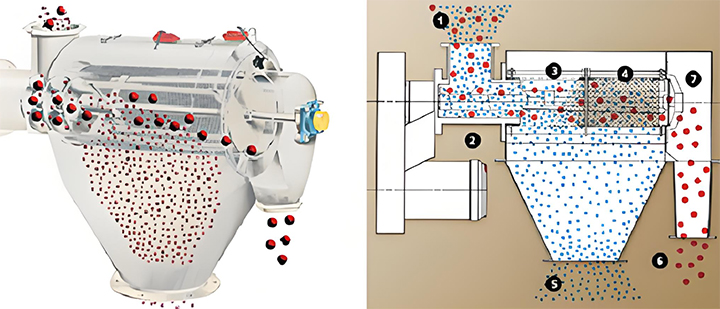

In a Centrifugal sieve machine, material falls from the feed inlet into the high-speed rotating drum. Centrifugal force propels particles toward the inner wall of the screen. Fine particles smaller than the sieve apertures are rapidly passed through the sieve by the combined forces of centrifugal force and gravity, becoming the undersize (fine material). Coarse particles or impurities larger than the sieve apertures are retained on the inside of the sieve. As the drum rotates or the sweeping arm pushes them, they are continuously conveyed to the coarse material outlet for discharge. The entire process is continuous, automatic, and highly efficient.

Centrifugal sieve machines play an indispensable role in numerous industrial sectors. When selecting a machine, consider material characteristics (viscosity, particle size, shape, friability), production capacity requirements, hygiene standards, and energy budgets. Centrifugal sieve machines are used for screening starch, flour, powdered sugar, cocoa powder, and separating soy milk residue from liquid. The pharmaceutical industry relies on them for fine grading of APIs, traditional Chinese medicine powders, and excipients. Furthermore, in the metallurgical and mining industries, they efficiently screen quartz sand, abrasives, and metal powders.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.