Chain Type Elevator Buckets also known as chain-driven vertical conveyors, are vertical conveyors based on chain drive. The chain pulls buckets to circulate along a sealed casing, continuously transferring granular, lumpy, and powdery materials from a low to a high position. Vertical lifting heights can reach 10-50 meters, with a single unit capable of producing up to a thousand tons per hour, perfectly suited for the material handling needs of large-scale production. The main frame is available in carbon steel and stainless steel. Smaller chain-type bucket elevators feature innovative adjustable rollers at the bottom, facilitating flexible movement and precise positioning, and reducing operating noise through a shock-absorbing structure, meeting the diverse needs of small spaces such as laboratories and workshops.

Based on customer conveying needs, we offer Chain Type Elevator Buckets in two main types: single-chain and double-chain. Single-chain models are compact, easy to maintain, and suitable for small to medium production capacities, while double-chain models offer even force distribution, strong load capacity, and are suitable for high specific gravity.

Single-chain bucket elevator: Utilizes a single high-strength chain as the traction mechanism. The bucket is suspended and fixed to the chain on one side, resulting in a compact structure, lightweight design, and convenient installation and maintenance. It features low power loss and is suitable for small to medium capacity operations with low to medium lifting heights.

Double-chain bucket elevator: Equipped with two parallel chains for synchronous traction, the bucket is fixed to two chains on each side. This ensures even force distribution, strong operational stability, and the ability to withstand heavy impacts. It is suitable for large-scale operations with lifting heights of 20-50 meters and high capacity.

Chain Type Elevator Buckets use high-strength chains for traction, offering strong load-bearing capacity. They can transport materials with high specific gravity and large diameters. The sealed structure prevents dust and leakage, ensuring stable operation, low failure rate, and wear and high-temperature resistance.

Strong load-bearing capacity: The structural characteristics of chain drive make it suitable for conveying materials with high specific gravity and large diameters, reducing the likelihood of belt breakage or bucket detachment.

High conveying efficiency: The continuous circulation bucket design enables uninterrupted feeding, with a capacity far exceeding traditional lifting equipment.

High stability: The transmission structure is simple and reliable, with a low failure rate. Routine maintenance only requires periodic checks of chain tension and bucket wear.

Customizable: Bucket shapes and materials can be customized according to material characteristics to meet the personalized needs of different industries.

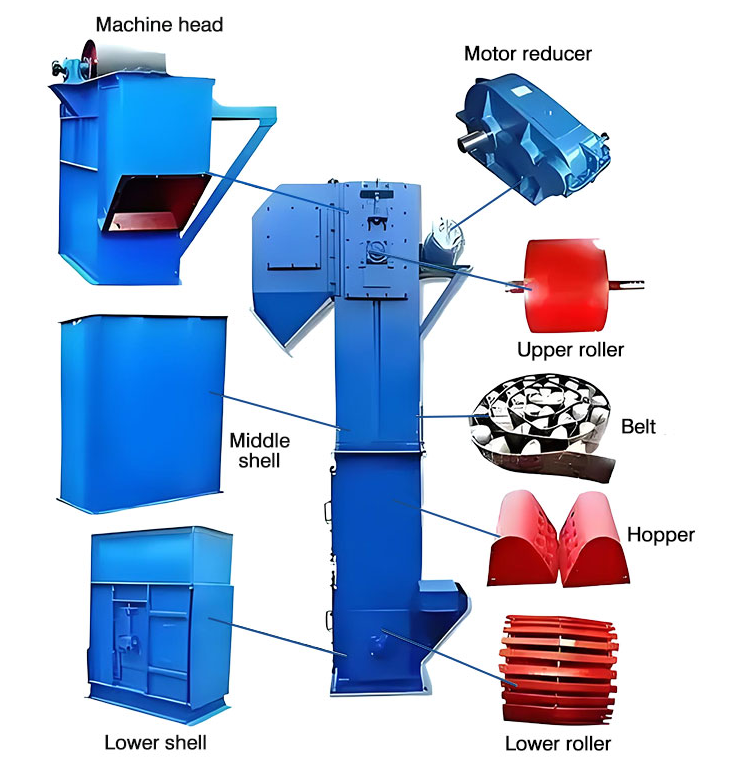

The Chain Type Elevator Buckets consist of five main modules: drive unit, traction chain, buckets, housing, and tensioning device. The coordinated operation of each component is essential to completing the entire conveying process.

Drive Unit: Utilizing a combination of electric motor and reducer, power is transmitted to the traction chain via sprockets, ensuring smooth operation.

Traction Chain: A ring chain forged from low-alloy steel using a carburizing and quenching process, offering more than three times the wear resistance of ordinary chains. The NE series plate chain bucket elevators further employ a double-row chain structure, increasing the load-bearing capacity to twice that of a single-row chain.

Bucket Design: Z-type medium-deep buckets and S-type deep buckets are developed to address different material characteristics. Suitable for various types of wet, sticky materials such as molding sand, fertilizer, loose coal, and crushed stone.

Sealed housing: Welded from 3-5mm wear-resistant steel plate, equipped with an explosion-proof observation window and an inert gas protection system. Automatic protection activates when dust concentration exceeds limits, ensuring safe operation in high-risk environments such as chemical and metallurgical plants.

Chain Type Elevator Buckets utilize a chain traction + hopper circulation system for vertical conveying. During operation, the drive motor rotates the head sprocket, pulling a high-strength chain and the hoppers fixed to it in a cyclical motion. When the hopper descends with the chain to the bottom inlet, it scoops up the material to be conveyed. It then moves vertically upwards with the chain, reaching the head sprocket. There, the hopper rotates in a circular motion, and under centrifugal force or gravity, discharges the material into the outlet, achieving continuous material transfer from low to high.

Chain-type Elevator Buckets, featuring high-strength chain traction and wear-resistant bucket design, are widely used in mining, building materials, chemical, and food industries. They can efficiently lift materials such as ores, cement clinker, fertilizer granules, and grains.

Building Materials Industry: Used for vertical lifting of raw materials such as cement, sand, and lime, connecting to production equipment such as rotary kilns and mills.

Mining Industry: Suitable for transferring materials such as coal, ore, and tailings, withstanding heavy-duty conveying under harsh working conditions.

Chemical Industry: Can transport fertilizer granules and chemical raw materials; stainless steel models meet corrosion resistance requirements.

Food Industry: Used for the storage and lifting of bulk grains such as wheat, corn, and soybeans; the sealed structure ensures material cleanliness.

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

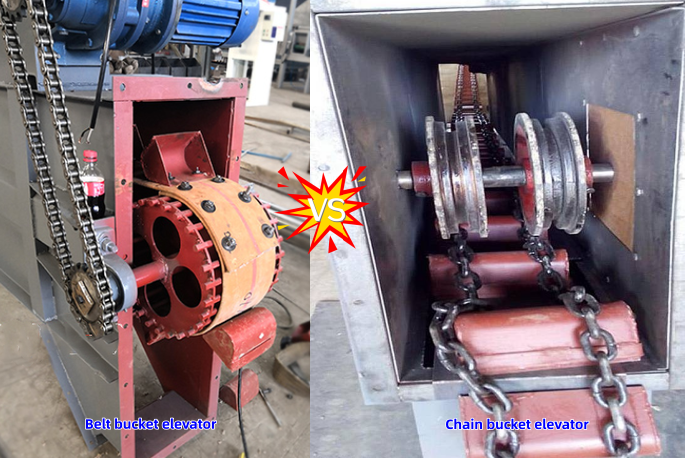

Belt-type elevators have low noise and high conveying speed, but are prone to slippage and are suitable for powdery materials; chain-type elevators have high strength and good wear resistance, and can carry large and abrasive materials.

Traction Mechanism: Belt bucket elevators use rubber or canvas conveyor belts as the traction component, with buckets fixed to the belt; chain bucket elevators use high-strength chains as the traction component, with buckets suspended on single or double chains.

Load Capacity: Belt conveyors have lower load capacity and are suitable for small to medium production capacity and lifting heights ≤30 meters. Chain conveyors have higher load capacity and can be adapted to large production capacity and heavy-duty scenarios with lifting heights of 10-50 meters.

Applicable Materials: Belt conveyors are suitable for conveying lightweight, fine-particle, and low-abrasive materials, such as grains, flour, and chemical powders; chain conveyors are suitable for heavy-weight, highly abrasive, and large-diameter materials, such as ores, cement clinker, and sand.

Maintenance Costs: Belt conveyors are prone to wear and aging, requiring frequent replacement, resulting in low maintenance costs and simple operation; chain conveyors have highly wear-resistant chains with a long service life, but their complex structure requires regular tension adjustment.

Working Environment: Belt conveyors are not resistant to high temperatures and oil contamination, and are suitable for dry, normal-temperature environments; chain conveyors are more resistant to high temperatures and corrosion, and can operate stably in harsh working conditions such as mines and building materials.

DaHan Machinery's Chain Type Elevator Buckets range from $550.00 to $6,800.00 per model. Prices may vary depending on the specific model, primarily due to chain type, lifting height, conveying capacity, and customized configurations such as stainless steel material, explosion-proof motor, and high-temperature resistant design. As a direct manufacturer, we eliminate intermediaries, support customized solutions, and offer free selection consultations, ensuring that customers of all sizes can obtain cost-effective vertical conveying solutions.

DaHan Machinery integrates independent R&D, customized production, and full-process service. Focusing on core technologies for heavy-duty vertical conveying, Chain Type Elevator Buckets encompass single and double chain series, employing high-strength manganese steel chains and wear-resistant steel buckets, adaptable to lifting heights of 10-50 meters and meeting the material needs of various industries. We support customized services for conveying capacity, materials, and drive methods, matching different scenarios such as mining, building materials, chemicals, and grain. We offer specialized configurations including carbon steel, stainless steel, explosion-proof, and high-temperature resistant options. Customization can be based on assembly drawings or tailored to your production site.

With its high speed, reliability, and strong adaptability, Chain Type Elevator Buckets have become the core equipment for vertically lifting powdery, granular, and small lump materials. Achieving continuous lifting through chain-driven buckets not only breaks through the spatial limitations of traditional conveying equipment but also demonstrates unique advantages under extreme conditions such as high temperature and high abrasiveness.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.