Corn kernels hose grain auger conveyor is designed for conveying corn kernels hose grains. Its flexible structure enables it to adapt to complex conveying paths and effectively solve space limitations. The core spiral is made of wear-resistant materials to ensure long-term stable operation. The conveying system integrates an adjustable screening device, and the appropriate screening mesh (for example: 20 mesh, 40 mesh) can be selected according to needs to effectively remove impurities and improve the purity of corn kernels hose grains. The conveying capacity is as high as 5-10 tons per hour, the motor power is 3kW, the conveying pipe diameter is 150mm, and the length can be customized according to actual needs. It is an ideal choice for corn kernels hose grain processing.

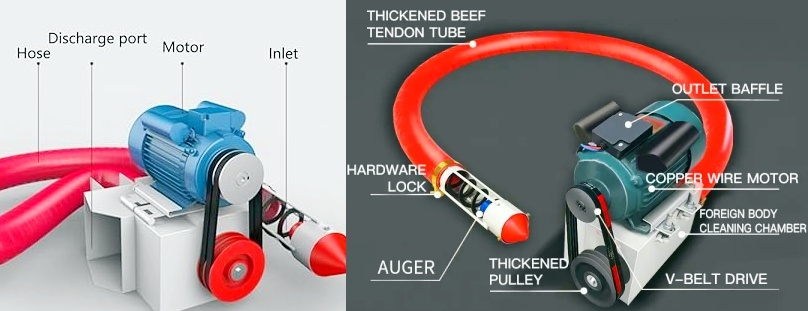

The core component of the corn kernels hose grain screw conveyor is a rotating spiral blade (or spiral) installed in the trough or pipe. When the drive device (usually a motor) drives the spiral to rotate, the spiral blade pushes the material forward in the direction of the spiral axis. The specific process can be summarized as follows:

① Feeding: corn kernels hose grain enters the trough or pipe through the feed port.

② Screw propulsion: The rotating spiral blade contacts the material, and due to the spiral rotation of the blade, an axial thrust is generated on the material.

③ Material movement: Under the continuous push of the spiral blade, the corn kernels hose grain moves forward along the trough or pipe.

④ Discharging: The material is finally discharged from the discharge port to complete the conveying process.

By adjusting the speed of the spiral, the flow rate of the conveyed material can be controlled. For inclined or vertical conveying, the friction between the material and the trough and the gravity of the material itself will also affect the conveying efficiency.

Spiral blades: usually made of steel or wear-resistant plastic, which push the material forward when rotating.

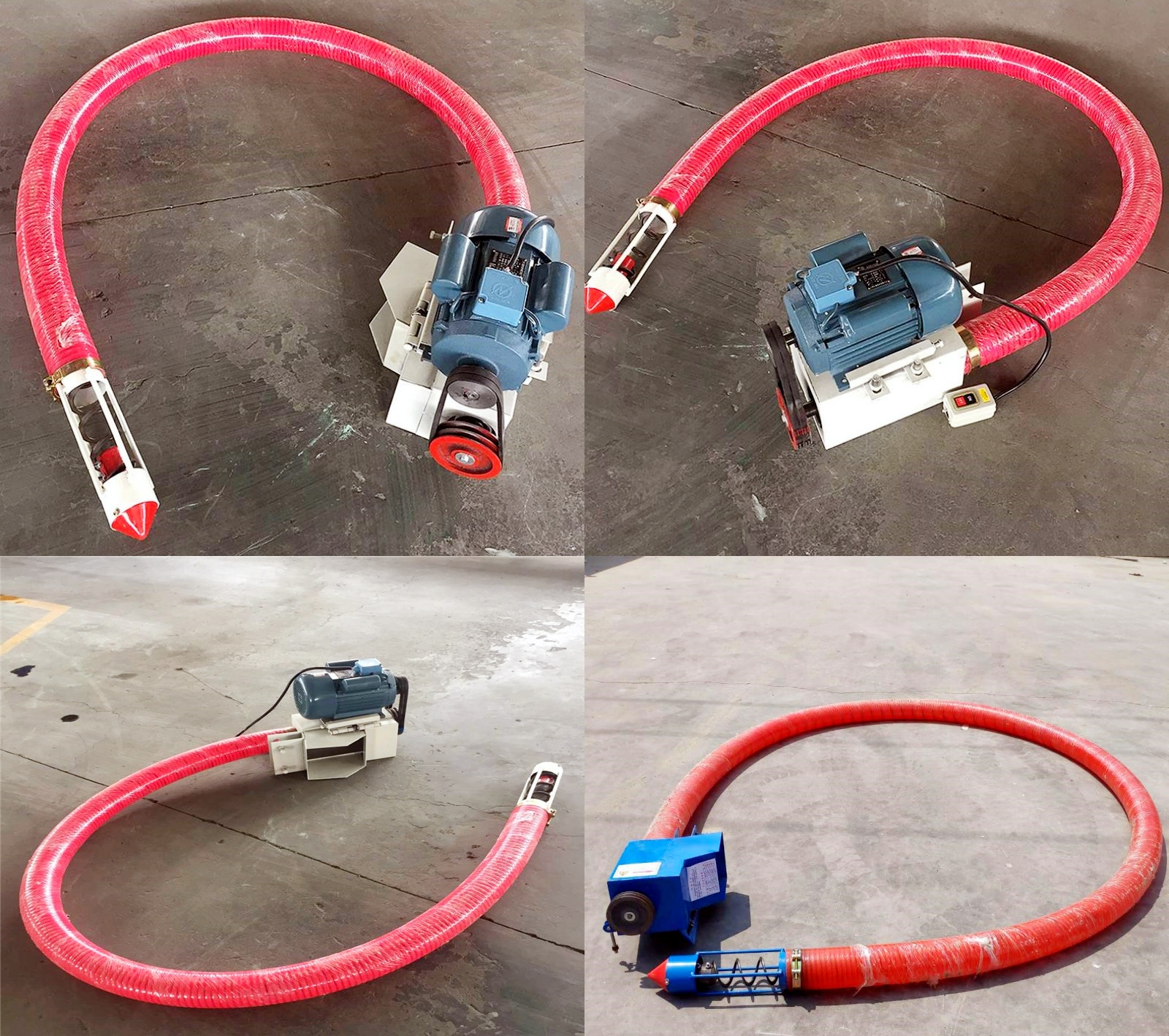

Flexible hose: The outer layer is made of wear-resistant rubber or polyurethane hose, and the inner lining is smooth material to reduce friction. The flexible screw conveyor uses a flexible hose as a trough, and the interior is a flexible spiral, which enables it to adapt to the curved conveying path.

Drive device: usually composed of a motor, a reducer, and a coupling, etc., to provide the power and speed required for the rotation of the spiral body.

Feed port and discharge port: used for the entry and discharge of materials. The design of the feed port should facilitate the inflow of materials, and the discharge port should be designed according to the subsequent process requirements.

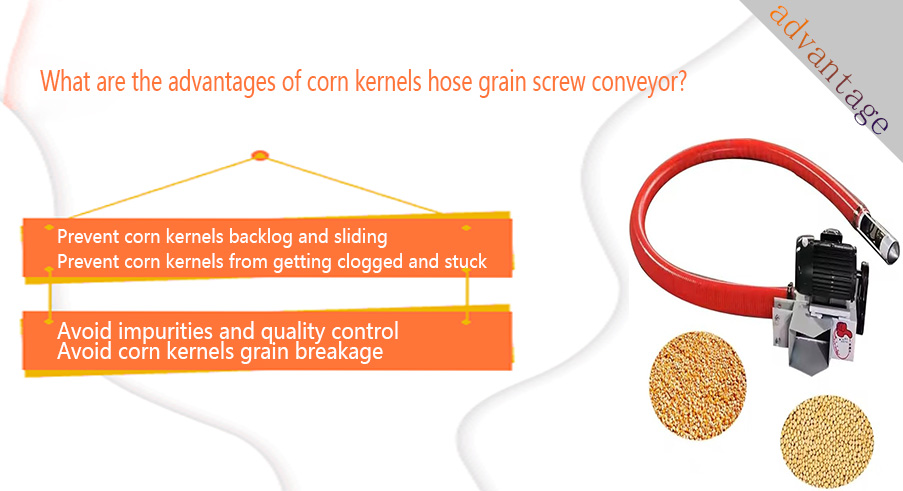

Prevent corn kernels backlog and sliding: The design of the spiral blade helps to ensure that the material is evenly distributed during the conveying process, and there will be no concentrated accumulation. Through continuous rotation, the corn kernels is pushed evenly, avoiding sliding or backlog caused by excessive accumulation.

Prevent corn kernels from getting clogged and stuck: The design of the spiral shaft allows the material to be continuously pushed forward in the hose, avoiding the blockage caused by material aggregation or uneven flow in traditional conveying equipment. Even at longer conveying distances and larger inclination angles, the material can still flow smoothly.

Avoid impurities and quality control: During the harvesting and processing of corn kernels, some impurities may be mixed in. The corn kernels hose grain spiral conveyor can simultaneously remove impurities larger than a specific mesh number during the conveying process, thereby improving the purity of corn kernels hose grains.

Avoid corn kernels grain breakage: For the more fragile corn kernels hose grains, some damage will be caused by the extrusion and friction of the spiral blades. The conveyor usually uses a shaftless spiral or a specially designed spiral blade to reduce the extrusion force on the material, thereby reducing the material breakage rate.

The following is a recommended table of different screening mesh counts for corn kernels hose grain screw conveyor:

|

Processing stage |

Recommended items |

Aperture (mm) |

Purpose |

Remarks |

|

Preliminary end of corn kernels kernels |

4-8 mesh |

4.75-2.36 |

Achieved the destruction of large particles (such as stones, transformation), and obtained complete corn kernels kernels |

Suitable for the front end of the pipeline machine to clean raw materials |

|

corn kernels kernel classification |

10-16 mesh |

2.00-1.18 |

Grading corn kernels kernel size, suitable for feed or food processing (such as distinguishing whole kernels from broken kernels) |

Can be used with the middle section of the pipeline machine Grade equipment |

|

Coarse grinding of corn kernels flour |

30-50 mesh |

0.60-0.30 |

Processing coarse corn kernels flour, suitable for feed or coarse grain products (such as corn kernels porridge) |

Pipeline machine is followed by coarse grinding and screening equipment |

|

Fine grinding of corn kernels flour |

60-80 mesh |

0.25-0.18 |

Producing fine corn kernels flour, suitable for baking or food processing (such as corn kernelsmeal) |

High-efficiency pipeline machine is required to ensure no siltation, and fine screen is configured |

|

Ultra-fine processing of corn kernels starch |

100-120 mesh |

0.15-0.125 |

Producing ultra-fine corn kernels starch or special powder, suitable for food or industrial use |

Pipeline machine needs anti-sticking design and high-mesh size net. |

corn kernels hose grain screw conveyor has shown broad application prospects in many links of the corn kernels industry chain due to its unique flexibility, closure and integrated screening characteristics. Its gentle conveying characteristics are particularly suitable for protecting the integrity of corn kernels kernels and reducing breakage.

① Farm harvesting and primary processing: After corn kernels is harvested, the kernels need to be quickly transported from the field to the primary processing site for threshing, drying and other treatments. Flexible screw conveyors can be flexibly arranged in the field, and closed conveying reduces the scattering and contamination of kernels during transportation.

② Grain storage and transportation: corn kernels is transported from the primary processing site to the granary for long-term storage, or transported between different granaries. corn kernels hose grain screw conveyors can be used for the storage and outbound links of granaries. Its closed nature reduces the risk of pests and mildew during storage.

③ Food processing (deep processing of corn kernels): After deep processing, corn kernels can produce a variety of food raw materials and products such as corn kernels starch, corn kernels oil, corn kernels grits, and corn kernels flakes. In these processing processes, corn kernels or its semi-finished products need to be transported between different equipment. Conveyors are used to transport corn kernels kernels, coarse starch slurry, etc. after corn kernels is soaked, and coarse particles or impurities can be removed during transportation.

④ Seed processing: corn kernels seeds need to be cleaned, graded, coated, etc. during processing. The flexible screw conveyor, with its gentle conveying characteristics, can reduce mechanical damage to fragile corn kernels seeds and ensure the germination rate of seeds.

In summary, the corn kernels hose grain auger conveyor, with its unique advantages, has shown important application value in all aspects of corn kernels from the field to the table, especially in scenarios that require flexible layout, reduce material damage and dust pollution, and is an ideal conveying solution. The screw conveyor with integrated screening function can further improve the quality of corn kernels products.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.