Laboratory Sieve for Calcining Clay is primarily used for particle size classification, impurity removal, and purity enhancement of calcined clay materials. Stainless steel is the mainstream material choice due to its corrosion resistance and ease of cleaning. Single-batch processing capacity is typically between 10g and 2kg, with sieving efficiency ranging from 5 to 15 minutes per cycle depending on the characteristics of the calcined clay and parameter configuration. Flexible sizes are available to suit different workstation spaces and experimental volumes. Mesh sizes can reach up to 1800 mesh, enabling the separation of ultrafine calcined clay. Equipped with a high-frequency vibration motor and an optional ultrasonic anti-clogging system, it effectively breaks up clay agglomeration and screen clogging, ensuring sieving accuracy and efficiency.

Laboratory Sieve for Calcining Clays are mainly divided into manual and electric types. There is also an ultrasonic model that can break up agglomerates and prevent clogging, suitable for fine sieving needs. Available in 2-8 layers, catering to various sieving needs.

Single-frame sieve: Consists of a single sieve frame and mesh, offering convenient operation. Primarily suitable for preliminary or coarse sieving where high precision is not required, it quickly separates large particles from calcined clay.

Test sieve: Typically composed of multiple stacked sieve frames with different apertures, driven by a vibrating motor to transmit vibration to the material within the sieve frame for sieving. Characterized by low noise, high efficiency, and high precision, it is widely used in laboratories for precise particle size analysis of calcined clay.

Ultrasonic test sieve: Based on a standard test sieve, it incorporates an ultrasonic system. Its unique sieving principle utilizes high-frequency electrical oscillations generated by an ultrasonic vibration power source, superimposed on the sieve surface and combined with low-frequency three-dimensional vibration, effectively solving the problems of fine powder agglomeration and mesh clogging caused by static electricity.

Striking sieve: Composed of a base, sieve fixtures, and transmission mechanism, it can be equipped with specialized clamps to hold multiple layers of test sieves. Its motor drives a gearbox via a synchronous belt, causing the main shaft to rotate. This, in turn, drives the eccentric wheel, push rod gear, and hammer to achieve material sieving. The impact sieve boasts high sieving efficiency, fast material discharge, thorough sieving, low maintenance costs, a simple structure, and standard bearings in rotating parts that are less prone to wear. It also offers the advantages of being environmentally friendly and clean.

The Laboratory Sieve for Calcining Clay offers significant advantages. Made of clean and corrosion-resistant stainless steel, it features high-frequency vibration and ultrasonic anti-clogging for improved efficiency. Its compact design saves space, and the quick-release screen allows for easy cleaning, meeting diverse needs for clay sieving in scientific research.

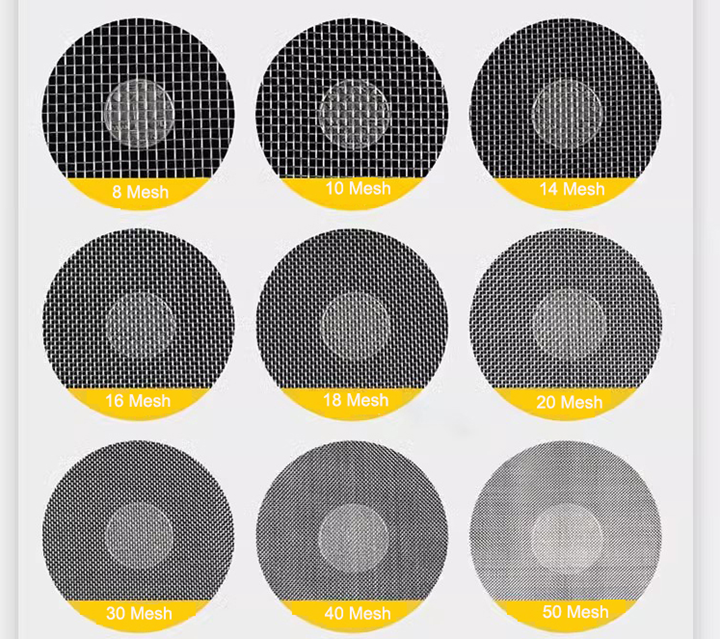

Error-free sieving: Supports customization of multiple screen sizes from 1-1800 mesh. The tensioned screen design ensures flatness and prevents loosening, guaranteeing the repeatability and accuracy of experimental data, and is suitable for precision experiments such as particle size distribution analysis.

Compact and space-saving: Adopting a compact structure, the machine body is only 200-300mm in size, occupying little floor space and can be flexibly placed on a laboratory workbench without taking up excessive space.

Easy-to-clean material: The main body is made of stainless steel, which is corrosion-resistant and high-temperature resistant, and can handle calcined clay residue and dust adhesion; the quick-release sieve design makes disassembly and cleaning convenient, avoiding cross-contamination of samples.

Simple operation: Equipped with a small high-frequency vibration motor, the vibration frequency is adjustable, and a single sieving takes only 5-15 minutes, far exceeding the efficiency of manual sieving; one-button start/stop + optional timer function, no complicated operation required.

High adaptability: Vibration parameters can be adjusted according to different calcined clay characteristics, suitable for experiments in various fields such as university research, geological exploration, and ceramic research and development, meeting diverse needs such as particle size classification and raw material purification.

The Laboratory Sieve for Calcining Clay is driven by a vibration motor, which transmits the vibration to the sieve frame through a vibrating plate. The material forms a three-dimensional vibration trajectory on the sieve surface, and particles smaller than the sieve holes fall layer by layer, achieving particle size classification.

Pretreatment: The calcined clay sample is passed through a 2mm sieve to remove large particle impurities.

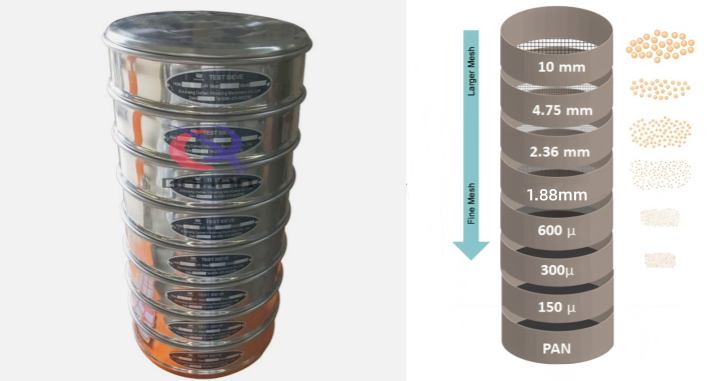

Sieve Frame Assembly: Stack sieve frames from bottom to top according to aperture size, from smallest to largest. Cover the top and install a receiving tray at the bottom.

Parameter Setting: Adjust the vibration time and amplitude according to the material characteristics.

Result Analysis: Weigh the residue mass of each sieve layer, calculate the cumulative sieve residue percentage, and plot the particle size distribution curve.

| Effective | ||||

| Shape | Size | diameter | Depth | |

| Biggest | Smallest | |||

| round | 75 | 75 | 65 | 25 |

| round | 200 | 200 | 175 | 25,50 |

| round | 300 | 300 | 285 | 75 |

| square | 300 | 300 | 75 | |

| No. | name | unit | parameter |

| 01 | frame | the number of layer | 1-8 |

| 02 | frame diameter | mm | &200 |

| 03 | sieve size | mm | 0.025-3 |

| 04 | noise | dB | less than 50 |

| 05 | amplitude | mm | 2-500 |

| 06 | vibration frequency | times/min | 1440 |

| 07 | outside dimension | LWH | 350*350*(300+n*5) |

| 08 | power supply | V;HZ | 200;50 |

| 09 | machine weight | kg | 2-500 |

| 10 | vibration motor | power | o.12kw |

Our Laboratory Sieve for Calcining Clay can be configured with up to 8 sieve layers in a single operation, easily achieving simultaneous grading of 1-7 particle size grades, perfectly meeting the core needs of multi-size particle separation in scientific research experiments. The 8 sieve layers adopt a stacked design, arranged from top to bottom according to mesh size from coarse to fine. After the calcined clay sample is placed in the top layer, through high-frequency vibration, particles of different sizes are separated step by step along the sieve layers, obtaining multiple graded samples in one operation. A single grading operation only takes 5-15 minutes, far exceeding the efficiency of traditional manual sieving.

The material selection for a Laboratory Sieve for Calcining Clay needs to balance corrosion resistance, cleanliness, durability, and experimental safety. 304/316L stainless steel is the most suitable material. Calcined clay may retain trace amounts of acidic or alkaline components after high-temperature treatment, and laboratory settings require extremely high sample purity. Stainless steel effectively resists the corrosion of these components, preventing oxidation and rust that could contaminate samples, thus ensuring the accuracy of experimental data.

We customize laboratory calcined clay sieve solutions for clients in different industries, providing suitable sieving equipment based on their production needs to support the smooth progress of scientific research and development in various fields.

New Cement-Based Material Development: When studying calcined clay as a supplementary cement-based material, laboratories need to precisely control its particle size distribution to analyze reactivity. An 8-layer laboratory calcined clay sieve with a 40-500 mesh gradient screen is used to separate seven particle size grades in a single pass. The equipment is constructed of 304 stainless steel to prevent corrosion from alkaline solutions, and high-frequency vibration ensures screening is completed within 15 minutes.

High-Dry-Strength Clay Formula Optimization: To develop crack-resistant clay formulas, ceramic companies' R&D centers need to control the particle size of calcined clay clinker and slurry. Laboratory calcined clay sieves are used, with a 250-mesh main sieve layer, supplemented by 200-mesh and 300-mesh auxiliary grading. A quick-release sieve design allows for rapid switching between sieve sizes.

Celadon-Colored Vitreous Clay Screening: Fine screening of calcined raw materials such as feldspar and kaolin is required. A combination of 80-200 mesh laboratory calcined clay sieves is used to accurately separate particles of different proportions, ensuring uniform mixing of components such as quartz and barium carbonate. The equipment's vibration parameters are adjustable to suit viscous materials, improving the uniformity of raw material mixing by 40% after screening.

Choosing a laboratory sieve for calcining clay should be based on the core experimental objectives, comprehensively considering factors such as material compatibility, sieving accuracy, and ease of operation.

Material Selection: 304 or 316L stainless steel is preferred. For routine calcined clay sieving, 304 stainless steel is suitable due to its resistance to atmospheric corrosion, ease of cleaning, and compliance with food-grade and general scientific research hygiene requirements. If the experiment involves corrosive environments containing chloride ions or sulfates, or high-purity sample analysis, upgrading to 316L stainless steel is recommended.

Sieve Configuration: The mesh size should match the experimental grading objectives, with a common range of 40-500 mesh. For example, ceramic formulation optimization often requires 200-300 mesh fine sieving, geological material analysis may involve 40-80 mesh coarse grading, and the development of new cement-based materials requires 500 mesh ultra-fine separation. When purchasing, confirm that the sieve is a standard woven or perforated mesh, and prioritize a tensioned fixing structure.

Number of layers and sieve size: The number of layers determines the single-pass classification capability. An 8-layer sieve can achieve simultaneous separation of 7 grades, suitable for multi-gradient particle size analysis; if only 1-2 grades of separation are required, 3-5 layers are sufficient. The sieve diameter is recommended to be selected based on the sample volume per pass; 200-300mm is the mainstream laboratory size.

Vibration performance: A high-frequency vibration motor is required to generate a three-dimensional vibration trajectory, breaking up the electrostatic adsorption and agglomeration of calcined clay. For processing highly viscous calcined clay clinker, it is recommended to choose a model with an ultrasonic auxiliary system, which can improve sieving efficiency by more than 30%.

The price range for the Laboratory Sieve for Calcining Clay manufactured by DaHan Machinery is $20.00-$3,680.00. The price difference is mainly determined by the configuration and functions. Basic models, such as manual single-layer sieves, are less expensive and suitable for simple sieving needs. Advanced models with vibrating motors and 3-5 layers of sieves are moderately priced and suitable for conventional multi-grade grading. High-end models feature ultrasonic anti-clogging systems, 316L stainless steel construction, 8-layer precision sieves, and timer control; these are more expensive and meet the needs of high-purity, precision experiments. Furthermore, the price will increase if you require the addition of an ultrasonic system or other accessories. We will provide a detailed quote based on your specific requirements.

What temperature can the machine withstand?

The Laboratory Sieve for Calcining Clay can withstand temperatures up to 150-200℃, with custom-made models capable of withstanding up to 300℃, suitable for sieving clay samples that have not fully cooled after calcination. The main body of the equipment is made of 304/316L stainless steel, which maintains stable mechanical strength and corrosion resistance even at high temperatures, preventing deformation that could affect sieving accuracy.

What is the highest mesh size?

The Laboratory Sieve for Calcining Clay can reach a fineness of 1800 mesh, meeting the requirements for high-precision clay particle classification. To achieve an 1800-mesh sieve, the equipment needs to be equipped with a high-frequency ultrasonic system to break up electrostatic agglomeration of clay powder and screen clogging.

What sieve diameters are available?

Our factory produces Laboratory Sieve for Calcining Clay with sieve diameters of 75mm, 100mm, 200mm, 300mm, 400mm, and 500mm. The choice can be flexible based on the sample volume per sieve, laboratory workbench space, and classification efficiency requirements.

Are you a factory/manufacturer or a trading company?

We are a direct factory with our own production line and plant, capable of supporting various customized needs. You don't need to worry about the extra costs of intermediaries or trading companies.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.