Laboratory test micro powder sieveis a special equipment for particle size analysis and sieveing test of fine powder materials. It is widely used in chemical, pharmaceutical, metallurgical, food and other fields. The equipment is usually composed of a vibration motor, a sieve frame and a control system, which can achieve effective classification of micron-level particles. The mesh size range is wide, generally 100 mesh to 500 mesh (equivalent to a particle size of 149μm to 25μm), and some high-precision models can reach 635 mesh (about 20μm). The sieveing process is stable and suitable for rapid sieveing of small batches and multi-specification samples, which is convenient for studying the particle size distribution and quality control of materials.

The laboratory test micro powder sieve is suitable for particle size analysis of various fine powders, especially for powdery and granular materials with a particle size range of 20 mesh (850μm) to 500 mesh (25μm). These materials usually have the following characteristics:

① Small particle size: mainly for powders with a particle size below 75 microns (200 mesh) or even finer, such as ultrafine powders of tens of microns or submicron level.

② Dry or nearly dry: Although some micro powder sieves are also suitable for wet sieveing, laboratory tests usually focus on dry sieveing to avoid agglomeration or other changes of samples in water media.

③ Good fluidity or fluidity can be improved by flow aids: For micro powders with poor fluidity, a small amount of flow aid may need to be added to improve sieveing efficiency.

There are many types of specific applicable materials, including but not limited to:

Metal powder: such as iron powder, copper powder, aluminum powder, stainless steel powder, used for powder metallurgy and 3D printing material testing.

Non-metallic mineral powder: such as quartz powder, talcum powder, kaolin, calcium carbonate powder, widely used in ceramics, rubber, coatings and other industries.

Chemical raw materials: such as polymer resin powder, catalyst powder, additive powder, used for chemical formula control and product development.

Pharmaceutical raw materials: such as Chinese medicine powder, API, and auxiliary powder, used for particle size control and quality inspection.

Food powder: such as milk powder, flour, starch, and cocoa powder, used for quality grading and standardized production.

The core function of the laboratory test micro powder sieve is to accurately grade and analyze powder or granular materials through sieveing technology, which mainly includes the following key functions:

Multi-level particle size separation: By superimposing sieves of different mesh sizes (such as 200 mesh, 325 mesh, and 400 mesh), the fine grading of powder samples is achieved, and the separation particle size range covers 0.5μm to 500μm, supporting the simultaneous acquisition of materials in multiple particle size ranges.

Particle size distribution analysis: Equipped with a high-precision balance and data acquisition system, it can quantitatively calculate the mass proportion of the sieve residue at each level, generate a particle size distribution curve (such as the RRB model), and provide data support for process optimization.

Agglomeration dissociation and anti-blocking: integrated ultrasonic vibration module (frequency 20-40kHz), effectively crushing soft agglomerates, avoiding hard particles from clogging the sieve, and improving the sieveing efficiency of micron-sized materials (such as nano-alumina).

Process verification and quality control: through adjustable amplitude (0-5mm) and sieveing time (1-60min) parameters, simulate actual production conditions, verify the stability of raw material particle size, and ensure that the product meets the standards (such as D50 particle size control).

The working principle of laboratory test micro powder sieve (ultrasonic test sieve) mainly includes the following steps:

Ultrasonic vibration: The equipment has a built-in ultrasonic generator that converts electrical energy into high-frequency sound waves to generate ultrasonic vibrations.

sieve excitation: Ultrasonic waves are transmitted to the sieve through the transducer, causing the sieve to vibrate up and down rapidly. This vibration helps the particles move better on the sieve surface.

Particle separation: With vibration, the movement speed of particles on the sieve is accelerated, and fine particles can pass through the sieve aperture more easily, while larger particles are blocked above, achieving effective separation.

Multi-layer sieveing: Ultrasonic test sieves can usually be installed with multi-layer sieves, which can sieve particles of different particle sizes at the same time, further improving the sieveing efficiency.

Collection and analysis: The sieveed particles will be collected in different containers for subsequent analysis and testing.

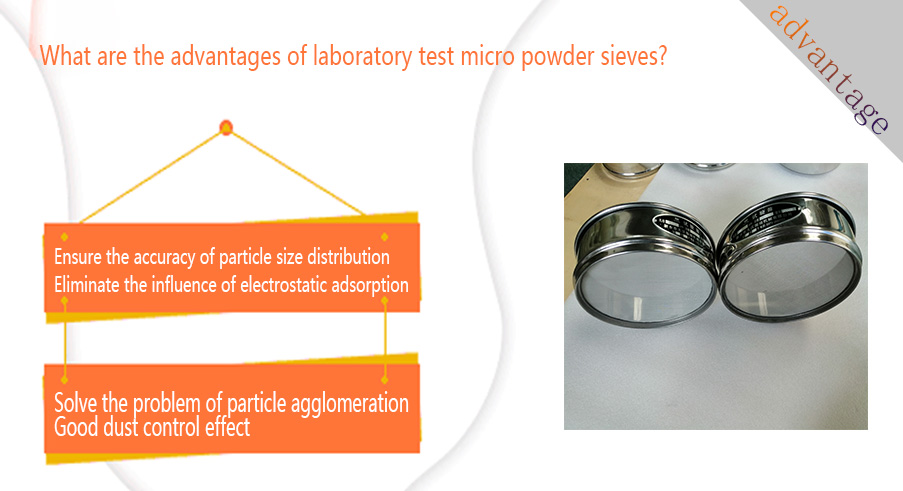

① Ensure the accuracy of particle size distribution: The diamond sieve adopts electrochemical corrosion or laser cutting technology, and the aperture error is controlled within ±1μm. With modular design, it is easy to quickly replace and calibrate. Some high-end models integrate laser particle size analyzers to monitor the particle size distribution of powder after sieveing in real time to ensure data traceability.

② Eliminate the influence of electrostatic adsorption: The surface of the sieve is coated with a conductive coating or embedded with metal fibers to avoid powder agglomeration or adsorption on the sieve due to electrostatic attraction. Wet sieveing can also effectively reduce the influence of static electricity. By adding liquid medium, the neutralization effect of the liquid is used to reduce the electrostatic charge on the surface of the particles, reduce the attraction between particles, and help to better sieve diamond particles that are prone to static electricity.

③ Solve the problem of particle agglomeration: The diamond test sieve can use ultrasonic vibration technology. Through high-frequency mechanical vibration, the powder on the surface of the sieve is kept in a suspended state, the adhesion, friction and agglomeration between particles are suppressed, and the agglomerated powder is redispersed. For some mild agglomeration caused by humidity and other reasons, it can also be solved by appropriately increasing the temperature of the sieveing environment or reducing the humidity, reducing the viscosity between particles caused by moisture and preventing agglomeration.

④Good dust control effect: The laboratory test micro powder sieves can be designed as a fully enclosed structure to reduce the contact between the powder and the outside air and prevent dust from flying out. At the same time, wet sieveing is used in the sieveing process, which can suspend the powder in the liquid and greatly reduce the generation and diffusion of dust. For some dry sieveing situations, a dust suction device can also be equipped to remove the dust generated during the sieveing process in time.

|

Features |

Ultrasonic Test sieve |

Traditional Micro Powder sieve |

|

Image |

|

|

|

Applicable Materials |

Nano Powder, Sticky Powder, High Purity Fine Powder |

Conventional Powder (No Agglomeration or Low Viscosity) |

|

Sieving Mesh |

Can reach 500 mesh or more (below 25μm) |

Usually ≤300 mesh (above 50μm) |

|

Net Blockage Risk |

Very Low (Ultrasonic Real-time Net Cleaning) |

High (Especially Fine Mesh sieve) |

|

Detection Accuracy |

Error ≤1% |

Error 3%-5% |

|

Processing Efficiency |

30%-50% Faster Under the Same Conditions |

Conventional Efficiency |

In short, the laboratory test micro powder sieve is an important tool for fine powder particle size analysis, quality control and scientific research and development, and plays a key role in many fields. It is particularly suitable for the sieveing of hard and fine powders, and is an important equipment for improving the quality and efficiency of powder sieveing. Do you have a specific powder type or application scenario? We can help you analyze it in more detail.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.