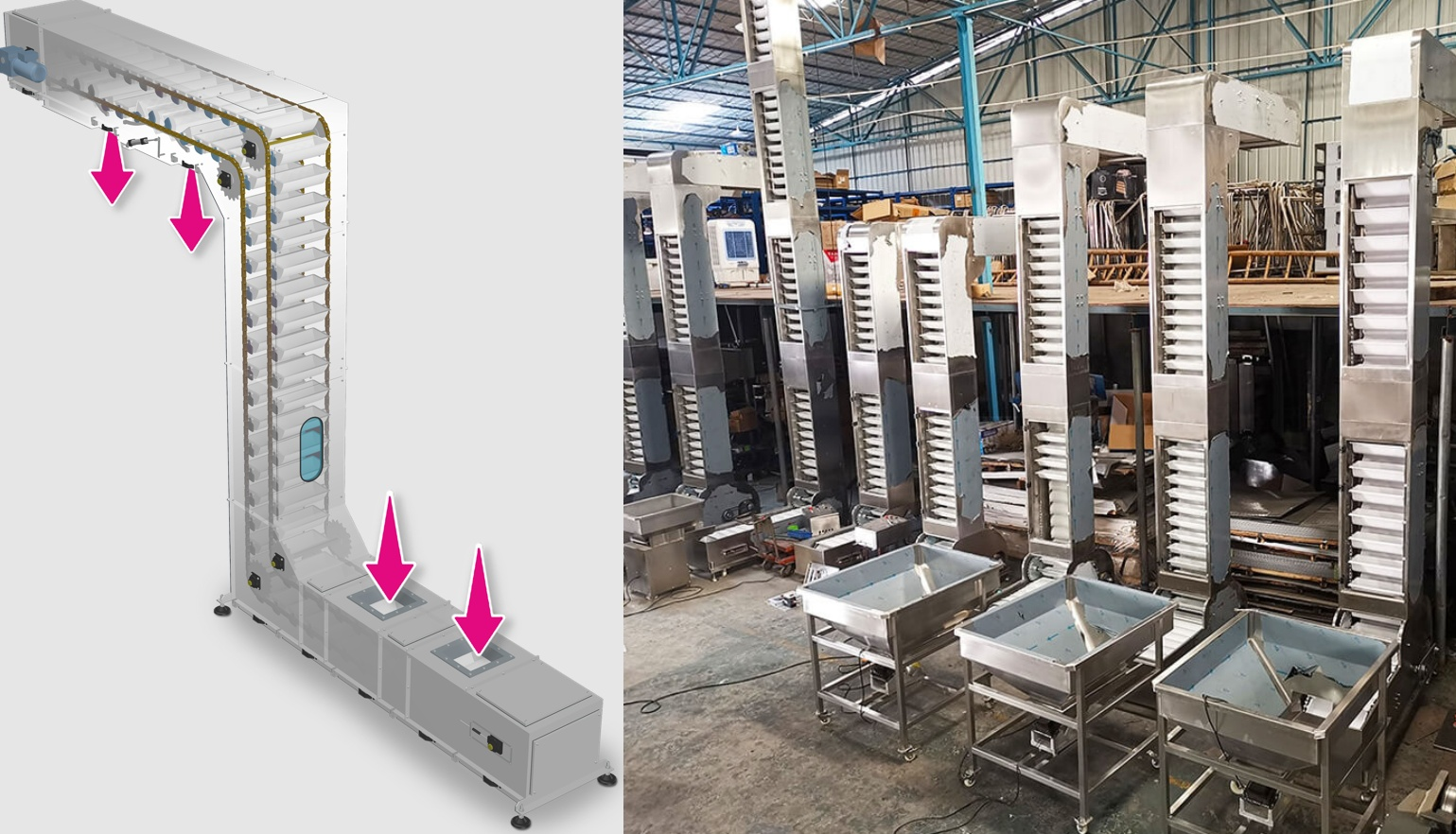

Z-type bucket elevator for grain peanuts is a lifting device specially designed for vertical and horizontal combined conveying of granular materials (such as peanuts, grains, nuts, etc.). Its design adopts Z-shaped structure, which enables it to achieve efficient material conveying while occupying a small area. The conveying capacity can reach 10-50 cubic meters/hour, and the lifting height can reach up to 20 meters. The hopper volume can be selected from 0.01 to 0.1 cubic meters according to demand, and the running speed is 0.5 to 1.2 meters per second, which effectively reduces material damage. The mesh size of the matching feed inlet screen can be customized, and 10-40 mesh is commonly used, which can effectively separate impurities and unqualified material particles.

|

Material type |

Typical representative |

Key physical parameters |

|

Granular materials |

Peanuts, corn, wheat, soybeans, sorghum |

Particle size: 2-15mm Bulk density: 0.5-0.8t/m³ Humidity: ≤14% |

|

Small block materials |

Peanut crushed, feed pellets, molasses blocks |

Particle size: ≤20mm Hardness: ≤3Mohs |

|

Powdered materials |

Flour, starch, milk powder (need to be conveyed in a closed manner) |

Particle size: <0.5mm Fluidity: ≥1.2 |

Feeding: Peanuts, grains and other materials enter the elevator through the feed port, and the inflow feeding method is adopted. The materials naturally flow into the hopper under the action of their own gravity. This method can reduce the crushing and blockage of the materials during the feeding process.

Lifting: After starting the drive device, the driving wheel drives the traction member to move, and the hopper fixed on the traction member rises cyclically, lifting the material from a low position to a high position.

Discharging: When the hopper moves to the top, it usually bypasses the top wheel and flips down, pouring the material into the receiving trough to complete the discharging process. The empty hopper continues to move down to the bottom and enters the next cycle.

Preventing peanut grains from breaking: The hopper of the Z-type bucket elevator usually adopts a shallow bucket or intermittent bucket design, and the peanut grains are piled up at a low height in the hopper, which reduces the extrusion and collision between materials during the lifting process. According to the characteristics of the peanut grains and the conveying volume requirements, it can be avoided that the material is broken due to inertia during the lifting process due to excessive speed. At the discharging end, the Z-type elevator uses a special discharging device to enable the peanut grains to be discharged smoothly from the hopper to prevent the material from breaking.

Avoiding the blockage of peanut grains: The feed port of the Z-type bucket elevator for grain peanuts is usually designed to be spacious and has a certain inclination angle, which facilitates the smooth entry of peanut grains into the hopper and reduces the possibility of material accumulation and blockage at the feed port. The spacing between the hoppers is carefully designed to ensure sufficient material delivery and avoid the hopper spacing being too small, which causes the materials to squeeze each other and become blocked during the lifting process.

Preventing the scattering of peanut grains: The casing of the Z-type bucket elevator adopts a sealed structure, which effectively prevents the peanut grains from being scattered due to vibration or airflow during the lifting process. Sealing devices are also set at the feed port and the discharge port to further improve the sealing and reduce the scattering of materials. The elevator adopts a high-precision transmission system and positioning device to ensure that the hopper can be accurately positioned at the feed port and the discharge port during operation to avoid scattering due to the position deviation of the hopper.

Reduce material residue: The inner surface of the hopper is made of smooth material, so that the material is not easy to adhere and remain in the hopper, which is convenient for cleaning after each conveying. The bottom of the hopper is designed to be inclined, so that the material can be completely discharged by gravity during unloading, reducing the residue of materials at the bottom of the hopper. Operators can regularly open the parts of the bucket elevator to clean the inside of the elevator to remove residual peanut grains and dust.

|

Project |

Parameter range or description |

Project |

Parameter range or description |

|

Model |

DH-Z100, DH-Z200, DH-Z300, etc. |

Discharging method |

Electromagnetic vibration, pneumatic control, gravity feeding, etc. |

|

Hopper material |

Food grade plastic (PP/ABS), stainless steel 304 |

Conveying capacity |

2~10 cubic meters/hour (m³/h) |

|

Hopper volume |

1L/1.8L/3.6L (optional) |

Lifting height |

26 meters (customizable, commonly 35 meters) |

|

Conveying direction |

Horizontal-vertical-Z-shaped three-stage combination |

Lifting speed |

0.5~1.5 meters/second (adjustable) |

|

Motor power |

0.75~2.2 Kilowatt (kW), according to the model configuration |

Applicable materials |

Peanuts, grains, nuts, pellet feed, etc. |

|

Material |

Carbon steel spraying/stainless steel (suitable for food grade requirements) |

Control mode |

Automatic/manual, can be linked with packaging machine/screening machine |

|

Equipment noise |

≤65 dB |

Applicable temperature range |

-10°C~+60°C |

1. Grain processing and storage: The Z-type elevator lifts the cleaned grain to the cleaning machine or storage bin. In the flour mill, the Z-type elevator can lift the upper part of wet wheat to the grinding equipment to avoid sludge squeeze damage. Grain is an important part of feed raw materials. The Z-type elevator is used to transport the crushed grain to the mixer to support the automated production of the feed factory.

2. Peanut processing production line: Z-type bucket elevator for grain peanuts can gently lift the shelled peanuts from the low feed inlet to the screening equipment. Before packaging peanut snacks (such as salt-baked peanuts and spicy peanuts), the Z-type elevator transports the processed peanut kernels to the multi-head weighing machine or the feeding port of the packaging machine, supporting multi-point discharging to match multiple packaging lines.

3. Deep processing of peanut grains: In the peanut butter production line, the Z-type elevator transports the roasted peanut kernels to the entrance of the grinder. When producing puffed corn flakes, oatmeal and other foods, the Z-type elevator transports grains to the seasoning machine. In the mixed nut packaging line, the Z-type elevator transports peanuts and other grains (such as fried corn kernels) processed by different processing equipment to the mixer.

4. Peanut grain and logistics: After the peanuts or grains are transported, they need to be piped from the transport vehicle or primary processing equipment to the high-level storage bin. Z-type bucket elevator for grain peanuts can realize the medium pipeline from the ground to the warehouse above 10 meters. Before the grains (such as millet and glutinous rice) are packaged, the Z-type elevator pipes the grains in the storage bin to the packaging machine or weighing equipment.

Z-type bucket elevator for grain peanuts is not only suitable for common agricultural products such as peanuts and grains, but can also be extended to diversified materials such as seeds, feed, and food intermediates. Through flexible design adjustments, it adapts to the physical properties of different materials while avoiding the space and damage limitations of traditional conveying equipment. When selecting the model, it is necessary to focus on the particle size, bulk density, humidity and brittleness of the material, and customize the solution in combination with the hygiene and explosion-proof requirements of the production environment.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.