Linear vibrating screen is widely used in the dried fruit industry for efficient screening and impurity removal of walnut kernels, pistachios, almonds, cashews, etc. The equipment is driven by a dual vibration motor to make the material jump forward on the screen surface in a straight line and perform classification according to different particle sizes. It can be configured with 2-4 layers of screens, and the commonly used screen meshes are 6 mesh (3.35mm), 10 mesh (2.00mm), 16 mesh (1.00mm), 20 mesh (0.85mm), etc., which can meet the screening needs of dried fruits of different specifications. It is widely used in the pretreatment of dried fruits before frying and the grading of finished products. It is an important equipment for improving product quality and packaging efficiency.

Linear vibrating screen for dried fruits is an efficient and reliable screening equipment in the dried fruit processing industry, mainly used for washing, grading, impurity removal and pretreatment of dried fruits before packaging.

Impurity removal: Dried fruits (such as raisins, almonds, walnuts, dates) may be mixed with branches, leaves, debris, sand and gravel during the picking or drying process. Linear vibrating screen for dried fruits can efficiently separate impurities and improve product purity through high-frequency vibration and multi-layer screen design.

Particle size classification: According to market demand, dried fruits are classified by size (such as large, medium and small particles). For example:

① Almond classification: first grade (whole), second grade (broken particles), third grade (powder).

② Raisin classification: special grade (full), first grade (standard), second grade (defective).

Vibration source drive: Two vibrating motors installed on both sides of the screen body rotate synchronously in opposite directions to generate a combined force to drive the screen box to vibrate linearly.

Material screening process: After the dried fruit raw materials enter the screen box from the feed inlet, they are affected by the vibration force and jump forward in a straight line on the screen surface. During the movement, the dried fruits pass through the upper screen according to the particle size, fall into the lower layer or are discharged from different outlets to achieve the effect of graded screening. Smaller particles such as impurities, debris, and dust are discharged from the fine mesh screen, and clean dried fruits are discharged from the discharge port.

Multi-layer screen screening: 2~4 layers of screens can be installed to achieve one-time separation of dried fruits into multiple specifications (such as large fruits, medium fruits, small fruits, and powder).

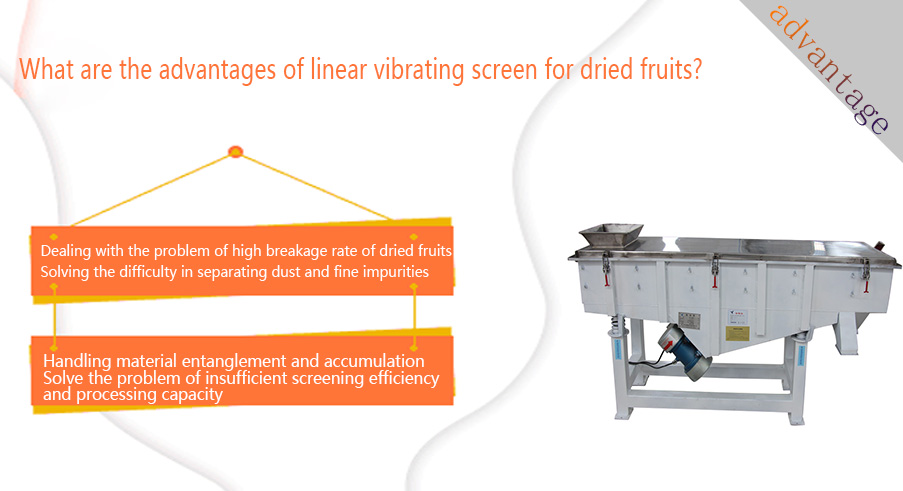

Dealing with the problem of high breakage rate of dried fruits: Severe vibration or improper equipment selection may cause some fragile dried fruits to break during the screening process, affecting product quality. By adjusting the parameters of the vibration motor and selecting the appropriate vibration frequency and amplitude, gentle screening can be achieved to reduce the impact on dried fruits.

Solving the difficulty in separating dust and fine impurities: Dust and fine impurities will be generated during the processing and transportation of dried fruits, and these fine particles are difficult to separate by simple gravity. Linear vibrating screen for dried fruits can gradually separate particles of different sizes, including fine dust, by setting up multiple layers of screens with different apertures.

Handling material entanglement and accumulation: Some dried fruits with fruit stalks or irregular shapes, such as dates and raisins, are prone to entanglement with each other or accumulate on the screen surface during screening. Compared with circular vibrating screens, the material movement trajectory of linear vibrating screens is more directional, which helps to evenly distribute the material on the screen surface and reduce entanglement and accumulation.

Solve the problem of insufficient screening efficiency and processing capacity: Traditional screening methods may not meet the needs of large-scale dried fruit production, with low efficiency and processing capacity. Linear vibrating screen for dried fruits has a large processing capacity and can continuously and efficiently process a large amount of dried fruits. The size, number of layers and vibration parameters of the screen surface can be customized according to production needs to achieve the required processing capacity and screening efficiency.

|

Processing link |

Applicable dried fruit type |

Recommended mesh number |

Corresponding particle size (mm) |

Number of screen layers |

|

Primary screening of raw materials |

walnuts, almonds, pine nuts |

8-12 mesh |

2.36-1.68mm |

single or double layer |

|

Fine removal of impurities |

almonds, cashews, pistachios |

14-20 mesh |

1.41-0.84mm |

double layer |

|

Particle size classification |

cashews, hazelnuts, macadamia |

6 mesh/10 mesh/16 mesh |

3.35/2.0/1.0mm |

three layers |

|

Screening after powder coating |

seasoned peanuts, honey walnuts |

40-60 mesh |

0.425-0.25mm |

single layer |

|

Slice thickness sorting |

dried mango, banana chips, apple crisps |

4-6 mesh |

4.75-3.35mm |

double layer |

|

Crumb recovery |

raisins, wolfberries, dried blueberries |

60-80 mesh |

0.25-0.18mm |

single layer |

Grading and screening of dried fruits (pistachios, walnuts, hazelnuts, etc.): After the initial shelling and drying, the dried fruits need to be graded according to the particle size to meet different market needs (such as export grade, large packaging, bulk retail, etc.). The linear vibrating screen can be equipped with multiple layers of screens to achieve 2-5 grades of grading at one time.

Dust removal and impurity removal (shelled or shelled dried fruits): After washing and drying, the dried fruits are often mixed with fine broken shells, dust, branches and leaves and other impurities. Through the linear vibrating screen for dried fruits with a screen of appropriate mesh size, these impurities can be effectively screened out to ensure the cleanliness of the product.

Separation of worm-eaten fruits and light fruits (walnut kernels, pine nuts, cashews, etc.): Some worm-eaten fruits or hollow fruits have low density and light weight, which can be separated by the linear vibrating screen for dried fruits combined with the air selection system or the specific gravity grading mesh screen structure, thereby improving the quality of the finished product.

Front-end pre-screening and back-end fine screening are used together: before the raw materials enter the wok, they are pre-screened through the linear screen to remove large impurities or unqualified fruit particles to avoid affecting the uniformity of frying; after frying, they are finely screened again through the linear screen to ensure the consistency and quality of the output.

Linear vibrating screen for dried fruits runs through the entire process of grading, impurity removal, dehydration, and packaging in the processing of dried fruits. Through precise screening and efficient processing, it ensures the standardization and quality stability of dried fruit products. Its ability to flexibly adapt to the characteristics of different dried fruits makes it an indispensable core equipment in the dried fruit processing industry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.