Mini Screw Feeder Required is a compact and simple continuous feeding device primarily designed for small-batch, high-precision material conveying. Its small overall size and minimal footprint allow for flexible material transfer between laboratories and various equipment. It is suitable for various materials including powders, granules, and small lumps, supports variable frequency speed control for quantitative feeding, and allows for selection of different materials based on material characteristics. The minimum pipe diameter is 89mm, and the length can be customized to fit your production site and requirements.

The choice of material for the Mini Screw Feeder Required directly affects its adaptability, durability, and material safety. We offer three materials: carbon steel, stainless steel, and PP, suitable for different industries and material scenarios.

Carbon steel: The surface can be painted or galvanized for rust prevention. Advantages include low cost, high mechanical strength, and resistance to minor wear and impact. It is suitable for conveying non-corrosive materials without hygiene requirements, such as sand, slag, and ordinary plastic granules.

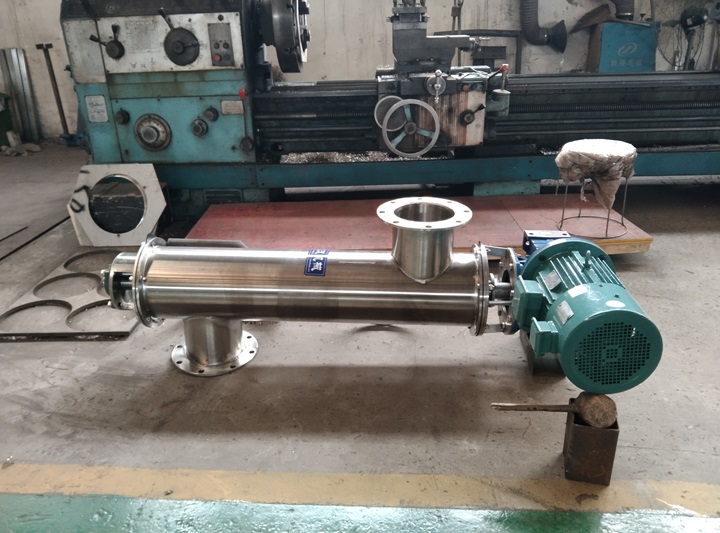

Stainless Steel Material: Made primarily of 304 or 316L stainless steel, the blades and conveyor cylinder are integrally molded with a smooth, burr-free polished surface. It boasts exceptional corrosion resistance and rust prevention, eliminating the risk of material contamination and meeting the hygiene standards of the food, pharmaceutical, and fine chemical industries. Suitable for materials such as flour, pharmaceutical powders, and corrosive chemical raw materials.

PP Material: Injection molded from high-strength polypropylene plastic, it is lightweight, chemically stable, and resistant to acids, alkalis, and organic solvents. Both the blades and conveyor cylinder are made of PP, preventing chemical reactions with materials. Suitable for conveying strong acids and alkalis, corrosive powders, etc., it is lightweight and easy to install, making it suitable for small-batch conveying in laboratories or short-term operations in corrosive environments.

With its core characteristics of being compact, efficient, flexible, and stable, the Mini Screw Feeder Required is the preferred equipment for small-batch, precision material conveying scenarios, highlighting its unique advantages through its structure.

Compact Size: Its small overall size allows for flexible integration into production line gaps or confined laboratory spaces, minimizing space requirements and adapting to complex layouts.

Precise Conveying: Equipped with a variable frequency speed control system, the conveying capacity can be precisely adjusted from 0.1 to 5 tons/hour, achieving quantitative and uniform feeding to meet the precision production needs of food ingredient preparation and chemical reagent addition.

Reliable Sealing: Utilizing a sealed conveying structure with seamless connection between the conveyor cylinder and the inlet/outlet, it effectively prevents dust, material leakage, and moisture contamination, making it suitable for powders and easily dusty materials, and meeting hygiene standards in the food and pharmaceutical industries.

Flexible Customization: Affordable price; pipe diameter, length, material, and drive method can be customized for different materials and scenarios, accommodating both small-batch laboratory testing and continuous production line operations, suitable for small and medium-sized enterprises and research institutions.

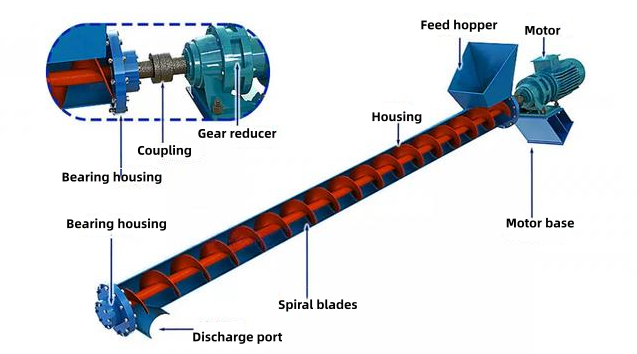

The Mini Screw Feeder Required consists of five core components: a screw shaft, housing, drive unit, inlet, and outlet. The screw shaft, as the main component, relies on welded helical blades to propel the material. Depending on the material's characteristics, the blades can be designed as solid, ribbon, or toothed helical surfaces. The casing is typically made of carbon steel or stainless steel, forming a closed conveying channel to prevent material leakage and external contamination. The drive unit consists of a motor, reducer, and coupling, using frequency conversion speed control technology to achieve precise speed control from 0-1500 rpm, ensuring the conveying speed is synchronized with the production rhythm.

When the drive unit is activated, the screw shaft drives the blades to rotate, and the material falls into the helical groove under gravity. The friction between the blades and the material causes the material to move in the direction of the screw's rotation, while the constraint force of the casing prevents it from rotating synchronously, ultimately converting it into linear motion along the axial direction. This rotation-to-linear conversion mechanism allows the equipment to operate stably in horizontal, inclined, and even vertical positions.

Mini Screw Feeders, with their compact size, precise delivery, and reliable sealing, have been deeply integrated into the production and research processes of multiple industries. Their applications are concentrated in scenarios requiring small-batch, precision material transport.

Food Processing Industry: Suitable for the quantitative transport of powdered/granular raw materials such as flour, starch, milk powder, and sugar. Examples include continuous flour feeding in biscuit production lines, precise addition of sugar powder during baking, and pre-mixing transfer of raw materials in meal replacement powder production.

Pharmaceutical and Chemical Industry: Used for small-batch transport of pharmaceutical powders and chemical reagents, such as precise dosing of pharmaceutical agents in pharmaceutical workshops and quantitative addition of colorants in paint production.

Electronics and New Energy Industry: Used for the precise feeding of positive and negative electrode materials in lithium battery production; and for the precise transport of tiny particulate materials such as solder powder and insulating powder in electronic component production.

Feed and Agriculture: Suitable for the quantitative pre-packaging transport of small particulate materials such as pet food and aquatic feed, or for small-batch raw material transfer during feed formulation development in laboratories.

Laboratory Applications: Used in materials research and chemical experiments for conveying and proportioning small doses of materials. The compact model can be embedded in the laboratory bench and, when paired with a high-precision speed-regulating motor, achieves stable feeding of milligram-level materials.

Packaging and Filling Industry: Used in conjunction with packaging machines for quantitative feeding and filling of materials such as coffee powder, protein powder, and flavorings, such as the precise filling of coffee powder in a small coffee capsule production line.

| Types |

|

|

|

|

|

|

| 100 | 160 | 200 | 250 | 315 | 400 | |

| Screw diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 |

| Screw pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 |

| Rotating speed(r/min) | 100 | 120 | 90 | 90 | 75 | 75 |

| Capacity Qφ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 |

| Power Pd 1=10m(kw) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 |

|

Specification only for your reference, size variable as per customer's request. Note: Please use other types of screw conveyors of our company for those larger than 1000 kg/h. |

||||||

The Mini Screw Feeder Required features a flexible installation design, allowing for wall-mounted, vertical, and horizontal installation options to suit different scenarios, depending on available space, production line layout, and material conveying direction.

Wall-mounted Installation: The feeder is fixed to a wall or the side wall of the production line equipment using the pre-installed mounting brackets. The conveying cylinder is horizontal or slightly inclined. This method requires no floor space and is suitable for workshops with dense equipment and limited space.

Vertical Installation: The feeder is placed vertically with the inlet at the top and the outlet facing downwards, fixed to the ground or platform by a bracket. Suitable for short-distance vertical material conveying, such as feeding material from the bottom of a hopper to the top of a mixer, or unloading material from above a packaging machine. Installation must ensure the machine's verticality, and the bottom should be secured with anti-slip pads or anchor bolts to prevent material accumulation and tilting.

Horizontal Installation: The feeder is placed horizontally on a ground bracket or production line platform. This is the most common installation method, suitable for horizontal material conveying. During installation, the bracket height can be adjusted to ensure precise alignment of the inlet and outlet with upstream and downstream equipment. The bracket must have sufficient load-bearing and shock absorption capacity to ensure stable equipment operation.

Our factory's Mini Screw Feeder Required is priced between $300.00 and $1,000.00. The price difference is mainly determined by the materials, specifications, and functional requirements. The basic model is made of carbon steel and equipped with a standard micro motor, suitable for conveying conventional materials without special requirements, and is priced at the lower end of the range. Models using 304/316L stainless steel or PP materials are priced higher due to the higher material costs.furthermore, the conveying length, pipe diameter, and whether a variable frequency speed control system or explosion-proof function is added will also affect the final price. You can provide us with detailed conveying requirements and production scenarios, and we will recommend or customize suitable conveying equipment based on your needs and provide a detailed quotation.

Dahan Machinery mainly focuses on the R&D, production, and sales of Mini Screw Feeder Required models, offering models in multiple materials including carbon steel, 304/316L stainless steel, and PP. Customization services for pipe diameter, length, and installation methods are supported. With stable conveying performance and a sealed, clean design, our products are widely applicable to various industries including food, pharmaceuticals, and chemicals. Our main products include tubular, U-shaped, and vertical screw conveyors, supporting customized designs to meet the conveying needs of different industries for powdery, granular, and small lump materials. We can provide suitable conveying equipment based on your production site and conveying requirements. Our products are sold globally and can be delivered to various manufacturers.

What vertical angle can it reach?

Our Mini Screw Feeder Required can achieve a vertical conveying angle of up to 90°. It overcomes gravity through centrifugal force generated by high-speed rotation and friction with the casing, achieving the vertical lifting of powdery and granular materials.

What is the maximum length?

The Mini Screw Feeder Required can be up to 30 meters horizontally, meeting the needs of long-distance continuous conveying; the maximum vertical lifting height is 6 meters, effectively saving space. Its length can be customized according to actual working conditions.

What types of materials is it mainly suitable for?

The Mini Screw Feeder Required is widely applicable, capable of conveying powdery materials such as flour and cement, granular materials such as plastic granules and fertilizers, and small lump materials such as ores and coal.

Can a weighing and metering version be made?

Yes, a weighing and metering version of the Mini Screw Feeder Required can be customized. By installing a high-precision weighing sensor and intelligent control system in the conveying section, the weight of the material is monitored in real time, and the screw speed is automatically adjusted to achieve dynamic metering and precise quantity control.

How to get an accurate quote?

To obtain an accurate quote for the Mini Screw Feeder Required, you need to specify parameters such as length, type of material being conveyed, and conveying capacity, and also indicate whether any special materials or functions are required. We will provide you with an accurate and detailed quote based on these requirements.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.