Screw conveyor for bulk materials are devices for the horizontal, inclined, or short-distance vertical transfer of various bulk materials such as grains, coal, sand, cement, and chemical powders. They enable efficient connection of materials from silos and stockpiles to production lines and storage facilities. They can be flexibly customized according to application scenarios and are available in horizontal, inclined, vertical, and mobile types based on installation method. Horizontal types are the most widely used, with conveying distances exceeding 30 meters. We support full-dimensional customization services, with materials including carbon steel, stainless steel, and PP, comprehensively meeting the personalized transfer needs of different customers.

We offer various types of Screw conveyor for bulk materials, tailored to customers' production needs and usage scenarios, adapting to the bulk material transfer requirements of multiple industries.

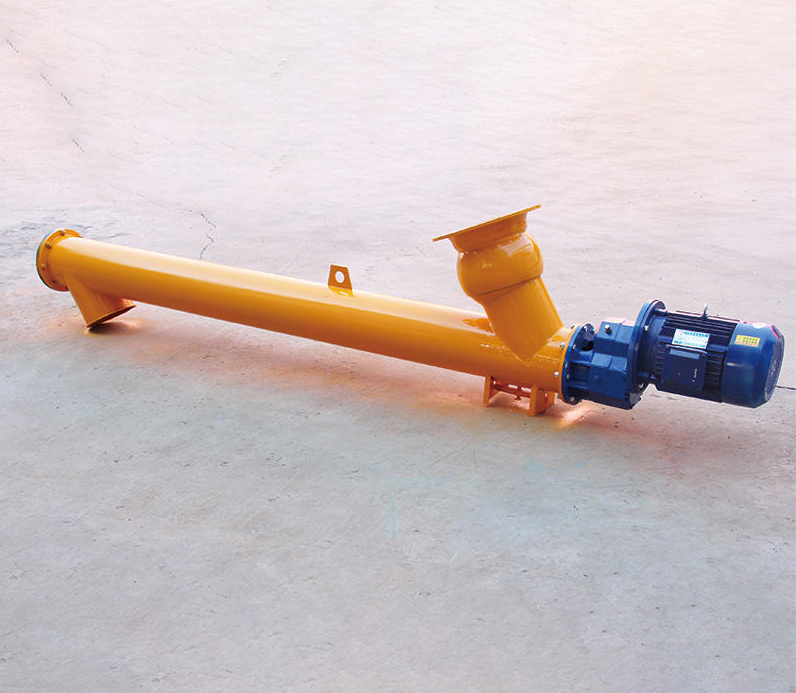

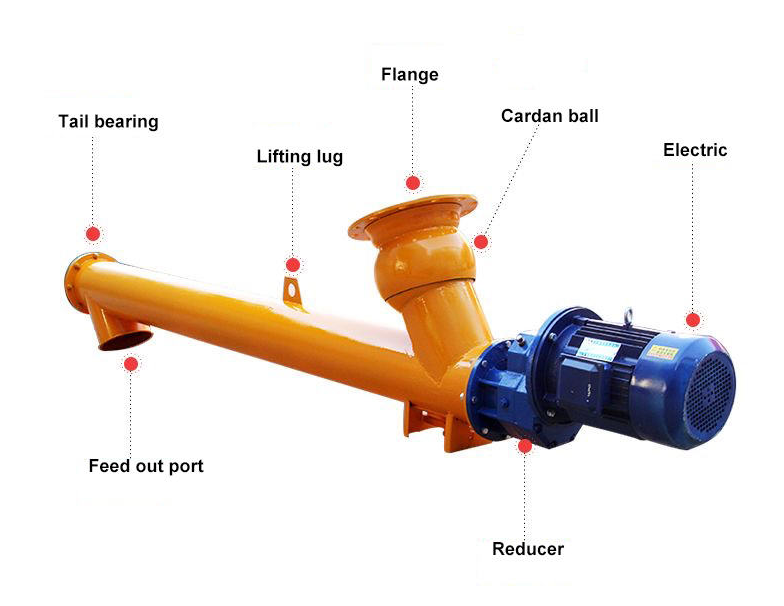

Tube screw conveyors: Utilizing a fully enclosed tubular structure design, the small gap between the screw blades and the tube wall minimizes material residue and dust leakage. Suitable for long-distance transport of powdery, fine-particle, and moisture-sensitive materials, supporting horizontal, inclined, and small-angle vertical conveying.

U-shaped screw conveyor: Featuring a semi-open trough structure, the trough can be covered as needed, combining convenient conveying with dust prevention. Compared to tubular models, U-shaped screw conveyors are simpler to clean and maintain; the screw blades and trough can be quickly inspected by opening the cover. Suitable for transporting lumpy, abrasive materials such as ores, sand, and coal.

Flexible screw conveyor: Replacing traditional pipes with wear-resistant flexible hoses, it features 360° free bending, allowing for flexible adjustment of the conveying direction, suitable for material transport needs in narrow workshops and complex environments. Its lightweight design supports both mobile and fixed installation, easily achieving horizontal, inclined, and vertical multi-directional conveying.

Stainless steel handheld screw conveyor: A portable model designed for loading and unloading small batches of scattered materials at multiple points. Lightweight and easy to operate, it can be operated by a single person. The body is made of stainless steel, which is corrosion-resistant, easy to clean, and meets the clean conveying standards of the food, pharmaceutical, and fine chemical industries.

With its compact structure and flexible customization, the screw conveyor for bulk materials offers advantages such as wide material compatibility, stable conveying, dust prevention, and convenient operation and maintenance. Multiple materials and models are available, allowing integration with various production lines.

Wide Compatibility: It can convey various bulk materials such as grains, coal, sand, gravel, and chemical powders, and is compatible with horizontal, inclined, and short-distance vertical conveying.

Stable Conveying: Utilizing the screw propulsion principle, it achieves continuous transfer, accurately connecting silos, stockpiles, and production lines, avoiding material accumulation and blockage, and ensuring stable production output.

Excellent Sealing Performance: The fully enclosed or semi-enclosed structure design effectively solves the problems of dust pollution and material loss, while preventing materials from being contaminated by the external environment.

Compact Structure: Small size and small footprint, requiring no complex infrastructure, it can be flexibly deployed in narrow spaces, and the flexible hose helix supports 360° adjustment of the conveying direction.

Customizable: Supports full-dimensional customization of materials, dimensions, conveying capacity, etc., adapting to different working conditions and material characteristics to meet individual needs.

A screw conveyor for bulk materials mainly consists of a drive unit, a screw, a conveying trough, and a sealing system. The drive unit uses a combination of a motor and a reducer to provide stable power to the screw and achieve precise speed control. The screw consists of a screw shaft and blades; the blade shape is designed according to the material characteristics, such as solid blades for conveying powders and belt blades for conveying granular materials. The conveying trough is mostly U-shaped or cylindrical, and materials include carbon steel and stainless steel to adapt to different working conditions. All components work together to ensure high-speed, stable, and sealed conveying of bulk materials.

The core logic of a Screw conveyor for bulk materials is screw propulsion. During operation, the motor drives the screw shaft and blades to rotate at high speed through the reducer. When the material enters the conveying trough from the inlet, it moves axially along the inner wall of the trough under the thrust of the screw blades and is finally discharged from the outlet, completing the entire conveying process.

Screw conveyors for bulk materials can transport various materials, including powders, granules, lumps, and specialty materials, by adjusting the screw diameter, speed, blade shape, and material.

Agricultural materials: Raw grains such as wheat, corn, soybeans, and rice, as well as processing by-products such as feed pellets, straw powder, and soybean meal. Food-grade stainless steel models are suitable to prevent moisture and mold growth.

Mining and construction materials: Coal, sand, ore, cement clinker, cement powder, fly ash, etc. These materials are highly abrasive; U-shaped or tubular models with carbon steel screws and wear-resistant manganese steel blades are recommended.

Chemical materials: Conventional powders such as fertilizer granules, PVC powder, and calcium carbonate powder, as well as corrosive acid and alkali materials such as citric acid powder and soda ash granules. The latter requires PP material models to prevent reactions between the material and equipment components.

Other materials: Plastic particles, industrial sludge, slag, etc. The machine structure and materials can be customized according to the material characteristics to achieve stable transport.

From mining sand and gravel to food and grain, and even corrosive chemical materials, we customize exclusive screw conveyor solutions for bulk materials for customers in different industries. Through precise matching of materials and models, we achieve high-speed, dust-free, and stable bulk material transfer.

Mining Industry: Needing to solve the problem of transferring large-diameter, highly abrasive materials in the workshop, we customized a U-shaped carbon steel screw conveyor with wear-resistant manganese steel spiral blades. The conveying capacity can reach 50t/h, and the conveying distance is 15 meters. After the equipment was put into use, it achieved continuous transfer of ore raw materials from the crushing workshop to the screening production line. The fully enclosed cover design effectively suppresses dust diffusion.

Grain and Oil Food Processing Plants: Needing to transfer clean raw materials such as wheat and corn, as well as finished feed pellets. We provided a stainless steel tubular screw conveyor. The body and blades are all made of 304 stainless steel. The equipment is suitable for narrow workshop layouts, achieving precise feeding from the silo to the milling production line.

Chemical Powder Production: Facing the challenge of conveying corrosive materials. Custom-made PP tubular screw conveyors are constructed entirely of acid and alkali-resistant PP material, equipped with corrosion-resistant seals to prevent reactions between materials and metal components. The equipment is used to convey materials such as citric acid powder and soda ash granules, with a conveying distance of 8 meters and a conveying capacity of 10t/h.

Selecting a screw conveyor for bulk materials requires careful consideration of two core factors material characteristics and conveying conditions. Environmental protection and customization requirements should also be considered. Based on material, choose carbon steel, stainless steel, or PP models; based on the application scenario, determine the type, such as tubular or U-shaped.

Based on material characteristics: For highly abrasive ores and sand, choose a U-shaped model with carbon steel and wear-resistant manganese steel blades; for clean materials such as food and pharmaceuticals, choose a tubular model made of 304/316 stainless steel; for corrosive materials such as acids and alkalis, choose a fully enclosed model made of PP material.

Based on operating conditions: For long-distance, high-capacity horizontal/inclined conveying, tubular screw conveyors are preferred, equipped with high-power drive units and intermediate bearings; for narrow spaces and flexible multi-directional transfers, flexible hose screw conveyors are selected; for small batches and scattered replenishment at multiple points, stainless steel handheld screw conveyors are chosen.

Based on site environment: For scenarios with strict dust control, choose fully enclosed tubular or flexible hose models with sealing components to prevent dust leakage; for operating conditions requiring frequent cleaning and maintenance, choose semi-open U-shaped models, allowing for quick inspection and maintenance of the screw blades by simply opening the cover.

Customization needs: For customers requiring customization, please specify parameters such as conveying capacity, factory length, and installation space. We will customize and produce suitable conveying equipment based on your specifications.

Dahan Machinery is a source manufacturer of screw conveyors, capable of customizing them in carbon steel, stainless steel, and PP materials. Core components such as the drive unit, screw body, and conveyor frame are all independently developed and manufactured, with strict control over material selection and process precision to ensure the equipment is suitable for material handling needs in mining, agriculture, chemical, and other industries. Our equipment is sold globally, meeting the conveying equipment requirements of customers in different countries.

With its compact and rational design of five core components, the Screw Conveyor for Bulk Materials achieves stable transfer of various bulk materials. Its flexible material and model customization options can precisely adapt to the working conditions of mining, agriculture, chemical, and other industries, while also offering advantages such as dust protection and convenient maintenance, making it a reliable choice for bulk material production and distribution.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.