When selecting an Ultrasonic Screen with 500 Mesh, the screen mesh should be changed based on the Ultrasonic Screen model. Generally, there are seven Ultrasonic Screen models: DHC-400, DHC-600, and DHC-1800. The Ultrasonic Screen with 500 Mesh requires an ultrasonic vibrating screen equipped with a 500-mesh screen. The pore size of a 500-mesh screen is approximately 25 microns. With such a fine screen, the biggest challenge when dealing with extremely fine, easily agglomerated, highly static, and highly viscous materials is no longer accuracy; it's preventing screen clogging to ensure continuous, efficient screening.

The main advantage of the Ultrasonic Screen with 500 Mesh is the addition of an ultrasonic screen cleaning and anti-clogging system. This is precisely because it adds a sophisticated ultrasonic screen cleaning and anti-clogging system. This system, consisting of an ultrasonic generator and transducer, converts electrical energy into high-frequency mechanical vibrations exceeding tens of thousands of times per second, which are transmitted directly to every mesh of a 500-mesh sieve via a dedicated resonant ring. This high-frequency micro-vibration creates a dynamic "bouncing wave" on the sieve surface, instantly and effectively breaking down the inherent surface tension, intermolecular adhesion, and electrostatic forces of ultrafine powders (such as turmeric powder and metal powder), thereby fundamentally addressing the physical root cause of sieve clogging. This feature is revolutionary for a 500-mesh sieve with a pore size of only approximately 25 microns, ensuring the sieve remains transparent throughout the screening process and significantly increasing screening efficiency.

Ultrasonic generator: Converts standard 50/60Hz industrial frequency electricity into high-frequency electricity between 18kHz and 40kHz.

Ultrasonic transducer: Converts high-frequency electricity into mechanical vibrations (i.e., ultrasonic waves) of the same frequency.

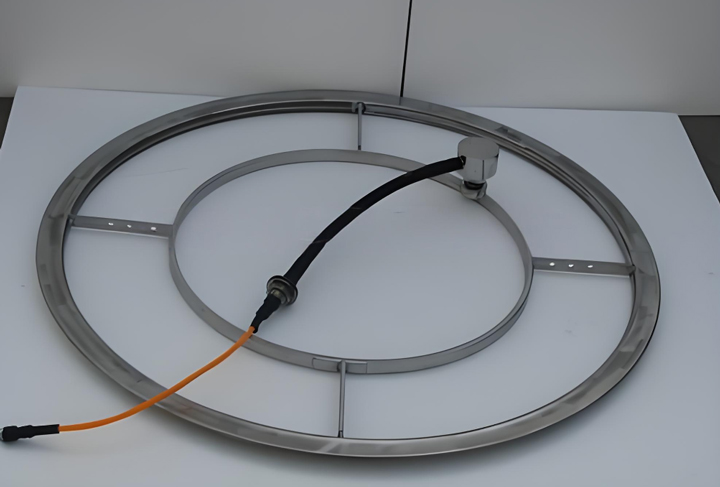

Ultrasonic resonant ring (vibrator): A specialized ring-shaped device mounted on the sieve that evenly transmits the high-frequency vibrations generated by the transducer across the entire sieve surface like a wave.

When configuring an ultrasonic screen cleaning system for 500-mesh ultrafine screens, the 500-mesh screen typically requires high-strength 316L stainless steel or more durable nickel mesh, depending on the material. This ensures stability and longevity under high-frequency vibrations. Ultrasonic systems of varying power levels may be required depending on material characteristics (such as specific gravity and viscosity), and selection and adjustment should be tailored to the specific situation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.